The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Headspace and Bullet Seating?????

Headspace and Bullet Seating?????Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

Folks, I am just getting back into reloading and will be engagining in real precision methods for the first time. I am having a custom built in .300 RUM. My builder tells me the following: 1. that he builds rifles with "tight chambers" 2. but that any factory round can be fired in them. 3. that he recommends the use of small based RCBS dies. THEN I buy an RCBS mic gauge to measure headspace and the instructions state that it cannot be used "...with small-based dies for use in semi-auto weapons." SO...I call RCBS to ask if the gauge will do me any good if I use small-based dies, but in a bolt action. The answer was that the mic gauge won't do me any good BECAUSE I AM ALREADY UNDER MINIMUM HEADSPACE. Question is--does that make sense????? Second question: I will be neck turning. So I am confused as to the order of operations--my understanding is that: 1. I full-length resize. 2. Then run the neck over a mandrel slightly smaller than the mandrel on the turning tool. 3. Then turn the necks. My question is--is that the correct order and most of all, do I have to take any further steps to size the neck prior to bullet seating--or does the mandrel used to open up the neck prior to turning take care of that? Thanks, Russ | ||

|

| One of Us |

#2). Read and follow the instructions that come with your case working tools. I have reamed a couple hundred necks but no outside turned as yet... #1). Just love "headspace." Look, SAAMI (Sporting Arms and Ammo Makers Institute or something like that) set standards. Guess what? They want all "factory ammo" to go into all "factory guns" or customers might be unhappy... makes sense... SO the "new" reamer cuts a chamber that is larger than the largest standard cartridge and guess what happens as the reamer wears??? Gets larger. Flip the coin. The "new" dies make the first hundred thousand cartridges to a size smaller than the smallest chamber but as they wear... rounds get bigger SLIGHTLY... Now you go and mess this all up. You have to have custom. The custom builder is not obligated to these standards. Usually these men make money providing higher/tighter standards that shoot better. He suggests "small base" dies, chances are you might be happier but you might do just fine with 60% of factory regular dies... If you care to do the research. RCBS has a device for working within the SAAMI standards. You have tossed those standards. Does it surprise you that the device won't do its work???? If you want to be hated, get a "no-go" gauge and take it to the used gun section and try it in used rifles. When new, it, the gauge, told the maker that his chamber would accept any factory standard round. You shoot a bit and the gun "loosens" up. Many factory rifles, USED, will take a no go gauge, no problem. It is the "field gauge" that predicts case separations often. (Or you can screw up the reloading and produce the same problems. Please don't.) Luck with your custom. Don't expect "standard rules" to apply. Might and things might be better. That is what you pay for. | |||

|

| new member |

Thanks, iiranger--and I have to confess I have heard most of that in one form or another--I am just having trouble wrapping my non-engineering mind around it. I watch the (to me at least) outstanding advanced reloading video with David Tubb, from Sierra. He takes a fired case--puts it into the precision mic gauge, and it shows about + .006 headspace. Then he tentatively sets the die, FLR the round and re-measures. And so on, kicking the neck back until he is at about .002 under minimum. So I am thinking--(always dangerous in a novice) what does "small based" mean anyway? I can see that it would reduce the size of the cartridge from the shoulder all the way down to the head, but wouldn't the lateral distance, such as from mid-neck to base, stay pretty much the same as SAAMI? It sounds like the answer is "no." So at this point, I have no idea how to set up my small based full-length resizing die. As to bullet seating, I am well-read up on how to determine experimentally how close to the lands I should place the ogive-(although I am struggling with why I need a comparator if I am already using the Stony Point depth gauge). But none of the instructions on any of my gear tells me whether, once I have expanded the neck with the special mandrell (for the sole purpose of keeping the brass from heating up while turning it)I then need to alter the neck size once again prior to seating the bullet. Maybe a better way to phrase this question would be as follows: When you FL resize the case using an expander ball, the ball will open the case enough to seat the bullet--there may be other negatives, but it will do that effectively. But then, if I use the mandrel to expand the case mouth enough to perform the neck turning, won't the bullet be too loose to seat? And if so, what's a mother to do? FL Rsize again???? Russ | |||

|

| One of Us |

I would wait until I have the rifle in hand before making any decisions. 1.The chamber may turn out to be within in standard specifications meaning standard dies will work fine. 2. While he may produce a "tight" chamber that may mean the diameter only not headspace. 3. If the gunsmith says all factory ammo will chamber by definition he is meeting the SAAMI specifications for headspace. If not the truly maximum cartridge will NOT chamber. 4. The RCBS tool is of no importance to you. there are other ways to measure cartridge headspace such as the Stoney Point/ Hornady tool. You did not say you would be getting a tight neck chamber. If you are, the gunsmith should tell you that. If so you will NOT be able to fire factory ammo safely. If you are getting a tight neck chamber you need to verify that your brass will chamber. Then turn the necks to the dimesnion the gunsmith specifies. If you have a blow up due to the tight neck you and the gunsmith can argue about it. If you don't get a tight neck I would just buy good brass, cull out the bad cases and forget about turning it. | |||

|

| one of us |

Small base full length resizing dies are smaller near the base of the die. They are designed to resize lower part of a case as well as the neck and shoulder. This type of sizing is needed if you are using cases that were fired in a full auto or semi auto gun. The extraction in these types of guns begins before the pressure is fully dissipated. Depending on the gun this may result in the body of the fired case being slightly enlarged at the portion nearer the head. The standard resizing die will not squeeze this part back to proper dimensions. Hence the advent of the small based die. I have used them when I come across a good buy in mil surp once fired brass. The "good" buys are usually machine gun fired or a mix. I have reloaded thousands of them for my M1A. Just small base sized once. Then they were in "spec" and worked well for several loadings with standard dies. muck | |||

|

| one of us |

"Tight chamber" means it's at the minimum SAAMI spec AND that the headspace (in this case bolt face to datum circle on the shoulder) is at -0.0010 to +0.0010 for the given chambering (most smiths set to 0.000 to +0.001, but I have at least 1 custom chamber set to -.001 with no throat). Small base dies reduce the base DIAMETER (go figure) slightly closer to the shell holder than a "standard" die does. Not needed in a bolt gun that is using brass fired from the same chamber. It's origional purpose was to bring back brass that had been fired in a sloppy chambered machinegun back to "normal" bolt gun diameter tolerances. As far as the video showing a +006 case being pushed back to -.002, well lets just say that Dave Tubbs is a pimp, and I'd take the advice of "Vince" the Shamwow guy before I'd listen to DT | |||

|

One of Us |

The best advice in all of the above. Russ, you also said

The neck needs to be expanded slightly larger than the mandrel on the neck turner, otherwise you will have a helluva time getting the mandrel in the neck. I turn for 3 tight necked custom rebarrels and I use the Lee Collet Neck Sizer which expands the neck to the exact size I need in order to use the Forster Hand Held Outside Neck Turner. As far as small based dies, I would wait until I had a problem before buying one. The problem will not show up until the 3rd or 4th firing when the brass loses it's springback and may get a little hard to work in the chamber. My 280AI is like that but I just live with the older brass being a little tight, my Redding Body Die does not size the pressure ring area small enough. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

Thanks, Gentlemen. All excellent information and I am digesting it. If I could ask you also to consider this updated information: In addition to the .300 RUM I have on the way--due in May--I also own, by the same builder--an ultra light in .300 Win mag for which I have never reloaded. Now, I don't know whether it has the same "tight" chamber as the coming, bigger rifle, but here is what I did: Last night, I ran a bunch of once-fired brass from factory loads (as well as the same unfired cartridges) through the RCBS mic gauge for headspace, with the following results: (12)Federal Premium 180 grain fired cases = average of .0015 over zero on the gauge. (15) RP 150 grain fired cases = average of .0015 over zero on the gauge. (8) Unfired, factory rounds Fed. Premium = average of .018 under zero on the gauge. (5) Unfired, factory rounds RP 150 grain = average of .015 under zero on the gauge. (5) Unfired, factory rounds of Hornady 150 grain = average of .009 under zero on the gauge. So bottom line was that the factory rounds were all over the landscape (although consistent within brand) as to the degree to which the round would rattle around back and forth in the chamber. But the fired cases all showed that they had been blown out to only ".0015". Am I missing something, or what does that indicate about the tightness (or lack of it) of my chamber--in terms of length. I realize it does not indicate anything about the tighness (or lack thereof) of the chamber from side to side. Also, am I correct in assuming what finally got through my dull brain (when I wondered why a case with .018 of headspace wouldn't blow up when fired) that the reason this did not happen was that the factory rounds all depend on headpace from the belt--and the .018 space actually exists between the shoulder of the factory round and the shoulder of the chamber? Asked another way: I am now getting ready to reload my fired cases for use in THIS custom chamber. And let's assume that, rightly or wrongly, I am going to take the advice of my builder and full-length resize. How far should I kick the shoulder back beyond where it ends up after firing (i.e., plus .0015 above zero on the mic gauge--where zero equals the minimum distance from the base to the datum point on the shoulder?) Russ | |||

|

| One of Us |

Your chamber may actually be .001 to .002 longer than what you have measured on your fired cases since the brass has some spring back. To find out what your chamber actually measures you might find a longer once fired case from another rifle and FL size it with out an expander until the bolt just barely drags on it when closing. If you have no cases from another rifle find a .458 Win case or other case that will be longer than your case are to the shoulder. Size this case down until it just barely chambers. Measure it and set your FL sizer to size about .001 to .002 shorter. Just for grins you could set it to be exactly .000 (the same) but I think you will pull the shoulder out every once in a while with the expander causing hard chambering. To get around this consider using a bushing die so no expander is required. | |||

|

| new member |

Gotch, SR. I had forgotten about the spring back of the brass. And I am hearing more and more about bushing dies as a way of getting past the problem of the chaos that can be caused by the expander ball--such as destroying the concentricity of the case. I was talking last night to the folks at Sinclair--quizzing them on the subject of whether I need to run a case through the FLR/Expander Ball (for bullet seating purposes) AFTER I have used an expander mandrel/neck turning tool on the case. He said ultimately for bullet seating I am going to need a bushing die. I really do appreciate the lessons. Russ | |||

|

| one of us |

Hey Russ, I'd suggest you are WAY over-thinking the entire process. That is common when a person trys to get their Brain wrapped around Run-Out and the Stoney Point or RCBS Case Measurement "Thingys". They can get you more confused than anything short of getting Loads off the net. If I am following this correctly, you already have a Small Base Die set for one of the rifles. If your GunSmith told you to use one, for sure listen to the man. You paid $$$BIG$$$ for his knowledge and experience with "your" specific rifle. If you want to load the most accurate ammo possible, toss the Thingy in a drawer(I'd use the Trash) and follow these Instructions on how to P-FLR after your Fire Forming Loads have been shot. Also, I believe you will find it beneficial to concern yourself with "1-rifle" and forget about the other one for awhile. Doesn't matter which one, just focus on one of them. Best of luck to you. | |||

|

| new member |

Hot Core: I suspect you are correct on the over-thinking part. I have already figured out one way I may have done that--my gunsmith also said he advised against turning necks--but I figured what the hell, if he can guarantee 1/2 MOA without turning necks,I can turn it into a one-holer. So maybe he knows something about the necks...? Thanks for the link--I am printing it out now and will proceed to over think that as well! | |||

|

One of Us |

Hey Russ, don't pay much attention to HC, he tends to "underthink" things sometimes Your measurements make perfect sense and what they are telling you is that there is a significant gap between the new case shoulder and the chamber shoulder. It is not really headspace since headspace on a belted magnum is measured on the front of the belt. I use the Hornady gauge and reload for 9 different 300 win mags. I do not measure the shoulder gap on every gun but have taken measurements on the following belted mags: Type gun / measurement on shoulder of new case / measurement on shoulder of fully expanded case / total shoulder gap Beretta Mato 300 win mag / 2.253" / 2.2725" / .0195" Beretta Mato 338 win mag / 2.0970" / 2.1240" / .0270" Winchester pre-64 264 win mag / 2.109" / 2.1385" / .0295" 6.5 rem mag custom / 1.768" / 1.785" / .0170" So you see the shoulder gap variations are much in line with your measurements of .0105" to .0195" (the distance difference between your minus measurements and you plus measurement). If you measure headspace on those cases (the amount of forward movement allowed before the belt stops it) then it varied from 0.00" on the custom 6.5 rem mag to .007" on the 338 win mag. But, as you have noticed headspace will vary as much because of the brass as the rifle chamber. Like SR4759 said, you need to allow for brass springback on new or annealed cases. That is why your brass will not be fully expanded until the 3rd or 4th firing. As far as turning goes, you need to know the neck size the gunsmith has on his reamer. Then you need to get the brass and see what neck thickness you have. Those 2 dimensions will determine if and how much you need to turn. I have to turn all 3 of my custom rebarrels and brass neck thickness varies from lot to lot. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Like woods, I like measuring instruments that give me hard data about my cases, chambers and dies. | |||

|

| one of us |

My guess this would have to be a custom made die. I doubt RCBS would make a Small Base 300 Rum die. | |||

|

| one of us |

I wore out on Turning Case Necks loooooong ago. It seems to be an integral part of the Run Out "Quest" that a lot of these guys spend many hours on. Our esteeeeemed member, Mr. Woods, is a guy that has lots of experience(aka totally wasted time As a simple suggestion, you might want to skip over it in the beginning and just see what your rifle does. You can always go to the Neck Turning later if you believe that will really help. You are welcome. My buddy Woods is absolutely correct about me trying to keep things simple. He mentioned Duct Tape and as luck would have it, not 4min prior to this I was PMing a guy about using Tape on the Muzzle of a firearm. Generally speaking, Baling Wire and Duct Tape will fix just about anything short of a potentially man-killing Blue Dot Ka-Boom. | |||

|

| new member |

I will repeat my thanks for all the great replies. Hot Core: It became clear early on that you are not a gadget freak just for the sake of using gadgets. I am beginning to get the picture that for the .300 RUM, I am just going to need to wait for delivery and the promised load development, and then sit down with my smith and have him fill me in on just what he uses and just what he does to achieve the 1/2 MOA--and follow that. My thinking--from what I have heard--is that he will zero in on the 180 grain Accubond--which would be ideal for me if the rifle likes it. I know there is a substantial minority who don't think much of that particular bullet, but the largest game I will be after are elk, and most of my shooting will be on our dog-sized Texas whitetails and Colorado Muleys plus the occasional unfortunate feral hog that is tearing up God's Country down here. As for the present, I intend to start working up some loads for the .300 Winnie ultra light built by the same 'smith. My thinking on resizing THAT round is as follows (comments appreciated.) Since all the fired cases from that rifle are a uniform (not just average) .0015 over SAAMI, from base to shoulder, and taking spring back into account, my first attempt should be with a standard FLR die (leaving neck sizing alone for now), and push them back, say, another .001 - .0015? Or would it be better just to not push them back this first time, until they have been shot again and grow a little more? Thanks to all of you. Russ | |||

|

| One of Us |

I will answer this in two sections One about technique and the other directly. 1. The amount of lube that you use can vary the amount of friction a case creates when it is being sized. So variations in the amount of lube cause slight variations in the distance from the head to the shoulder. The speed that you raise the press ram also causes slight variation by changing the amount of time the brass has to move and permanently yield. You can minimize the variations by A. Sizing the case slowly especially the last 1/4 of the press stroke. B. Making sure the amount of lube applied is somewhat uniform....difficult to do. C. Size the case, retract it from the die just far enough to turn it 180 degrees (do not pull it over the expander ball) and slowly resize again. The preceding technique is no difficult or time consuming but the second sizing pass will insure that the head to should distance is about as uniform as you can make it. I use a lot of once fired range brass that come from multiple guns and I use this technique to ensure they size to the same final dimension. 2. To answer your question directly I would try to duplicate your existing dimension exactly by setting the sizer using a case fired from a rifle with a larger chamber. If you ever run into tight chambering later just adjust the die down .001 to .002. But only make the adjustment if your head to shoulder measurement shows that the cases really are longer. All of this assumes you do no pull the shoulder out with the expander ball. You can verify that by measuring the sized cases. I know this may seem tedious but once set, with your numbers recorded for head to shoulder length, you will probably not have to mess with it again. | |||

|

| new member |

I think I get the picture on the sizing technique--something I had never heard of--and somewhat akin to the trick of rotating the case slightly 3-4 times while seating the bullet to somewhat lessen runout. With regard to trying to duplicate dimensions exactly, would it be necessary to use a fired case from another rifle, or could you just start with an unfired case? Also, while I have you on the phone, when I quit loading years ago, the only lube anyone used was the pad--what is the general opinion among experts these days of the spray-on variety? All over the landscape? uss | |||

|

| one of us |

Just push it in by hand, no press or hammer needed. Naw, I do use a Press and just try to be consistent with the few things I do. Reloading is very interesting to discuss because there are so many ways to go about doing it. It seems that nearly everyone does some portion just a bit different from someone else, and most still result in Safe Accurate Loads. That doesn't necessarily mean one person is right and the other wrong, just lots of ways to accomplish the end result. As long as it is Safe, a person should use the Methods that make sense to them. Sounds like a fine Plan to me. Before I ever got on the net, I do not remember ever hearing a Bad thing about a Bullet. People would occasionally select the wrong one for the task at hand, but the blame went to the person doing the Bullet selection, not the Bullet. Then I get on the net and hear all kinds of stories about how a particular Bullet is Bad because the "Bullet" __________! Every Bullet made has had some kind of Horror Story associated with it now - even the Nosler Partition. And when I think of hundreds of Hunters I've been around making many MANY thousands of Kills, I can't think of an instance where the Bullet being used did not perform as it was designed to work. Strange! On the other hand, they are "Man Made" which means to me there are no Perfect Bullets. Even the best of them "should have" a faulty one sneak out of the Factory on occasion. Did see some Set-Up Bullets that got into Factory Ammo one time. Horrible mess of Bullets, but the problem was with the Production Foreman using them to make production. However, that ammo "might" have given the appearance of a Bullet Failure, but you could not keep it on a sheet of paper at 100yds. And I've seen FMJs with Lead smears at the Base,cannelures skewed and tips bent on them. But, if you can get the Accubonds to shoot well in your rifle(which should be easy), they should do just fine. Occasionally a particular rifle just won't shoot a specific Weight or Style of Bullet. No logical reason, but it happens. And you would know by looking at the Targets, You "might" be able to P-FLR with them now. When you push the Shoulder back, it results in a shorter overall Case Life. If you Hunt in Dangerous Game country however, all your Hunting ammo should be FLRed. A small speck of Sand or any kind of Trash could create a jam at the worst possible time. Soooooo, just eliminate that as an issue. But most of all, use a Method that makes sense to you(and Trash the Thingys Best of luck to you. ----- By the way, surely you do know about the never improved upon, Creighton Audette Load Development Method. It allows you to get to the best Harmonic Node in the shortest amount of time. Best of luck to you. | |||

|

| One of Us |

The reason for using a fired case from a rifle with a bigger chamber is just to get a longer head to shoulder dimension to start on. In other words one that is known to be long enough that the die HAS to push it back some to reach you chamber dimension from head to shoulder. If you don't have such a case just do the best you can with your existing brass. My reason for suggesting an over length case is because I use cases fired in other rifles and I want them all to fit. In regard to the spray lube I have never used it. I am currently on a 10 year run with the Imperial lube. I do some heavy case forming from time to time and I have found the Imperial the best for that task. I have heard a lot of good things about the spray lubes but I have my doubts about using them for forming cases. I apply the Imperial wipe on lube with my fingers. Yes it is a little greasy but I get the best possible feel for the distribution of lube on the case. | |||

|

One of Us |

IMO the 300 RUM is tailor made for the 200 gr Accubond. The ballistic coefficient at .588 is outstanding and that bullet is consistantly more accurate than the 180 in over a dozen 300 win mags and 30-06's I load for. My 30-06 hunting load is a 200 gr Accubond with a full case of RL22 and even though slow at ~2650 fps is always accurate  In the 300 win mag it is hard to get much past 2900 fps but in the 300 RUM at 3000 fps + that would be a show stopper. The 200 gr Accubond is in a class by itself. As far as setting your shoulder position the easiest way to do it is to let your rifle tell you where to push it back to. Set your rifle up and chamber a fired case, if it chambers easily without any difference in force needed to close the bolt on an empty chamber, then just neck size. When you get a crush fit set your die to give a very very slight crush fit by repeatedly sizing, setting your die and chambering the case. IME, you won't get a crush fit until at least the 3rd firing. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

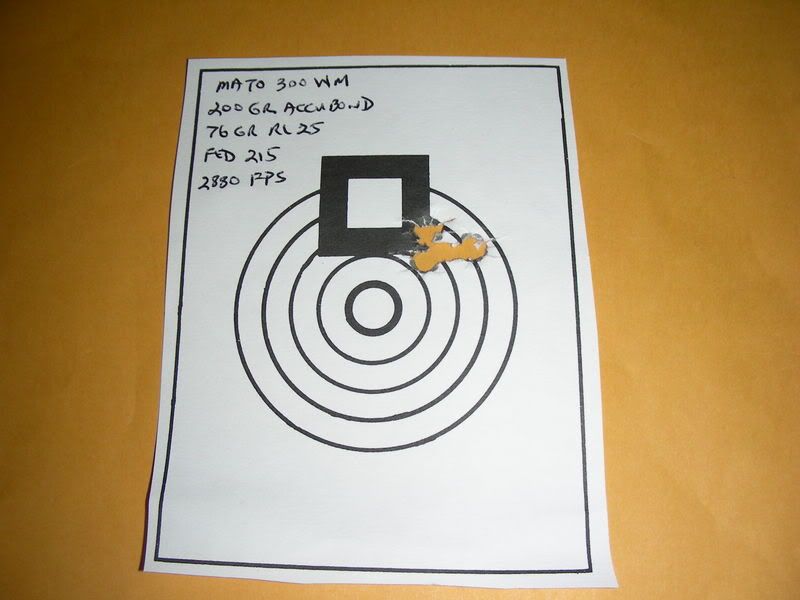

Thanks, SR. That explains it. Woods: I have looked longingly at that BC for the 200 Accubond--there are a few things that worry me about that bullet for my own use: First, I am something of a recoil wuss (I know, I know, what the hell am I doing with the RUM even with an excellent muzzle brake!) Second, I doubt I will ever shoot much at what most folks call the "long ranges" where that bullet will outrun the 180, and third, for whatever reason, my builder uses a 1/11 twist for both magnum thirties. I'm not certain whether that will stablize the 200 (although it is on my list of things to whine about next. But if it would stabilize, and its superior accuracy translates to my rifle--as it would seem it would--not much to argue with in that case. And yes, I would call that target evidence of accuracy--if you hadn't pulled that top one a foot high.  (Lord help me, but I love the icons on this board!) By the way, I owned two Steyrs and loved both of them--one an SSG in .308 that weighed nearly 12 pounds with the scope, with double set triggers, that I hauled it up to my tree blind in South Texas (back in the days when I used to drink bourbon before the hunt (Arghhh,) somehow managing not to touch off a round into my foot or groin, and shot two pathetic whitetail bucks at about 35 yards. The second was a Professional--one of a very few, I understand, with a 20 inch barrel--great, accurate rifle. I gave it to a cousin who owns the place next to mine who had never hunted, and he has turned into death machine for deer and hogs. Russ | |||

|

| one of us |

Lots of folks own cattle where I am too, but most are loved after butchering. ----- Forgot about the Lube. The Imperial Sizing Die Wax that SR4759 mentioned is indeed great stuff. Completely agree with him that when it is time to Reform a Case, it is the best stuff to use. And works great in regular Resizing as well. I also still use the old Lube Pad with RCBS or Hornady Lube. Works fine and I toss them into the Tumbler to remove it. I have some of the Spray Lube and it is OK if you follow the directions, but I prefer the Lube Pad. ----- Hey Woods is that one of Bounty Hunter's groups at 300yds, or one of yours at 25yds? | |||

|

One of Us |

Jealousy Hey Russ, I found a target of the 300 win mag and the 200 AB  The thing is that in several different 300 win mags, if I moved the velocity up to ~2925 or so then accuracy degraded. Usually or sometimes (I don't want to start another Epiphany thing) there is another node of accuracy if you could bump the velocity up another 150 to 200 fps. That would fit the 300RUM and I would be looking to push that bullet at 3050 fps or so and that would be a real show stopper for Deer or Elk. Not so fast it gets squirrely and fast enough to hold velocity and energy at the longer ranges. Anyway that's what I'd do. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

Good group--I am sorry to say about like my best ever--with a .243 bull barrel 700 Varminter many years ago As I said before,I am a little worried about the 200 in the RUM at 1/11 twist--I called Nosler today and they told me they recommended 1/10. Soooooo..... Russ | |||

|

One of Us |

And I used to think of myself as a good salesman! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

I'm not sure you understood me,Woods--what I meant was that in my whole life, using a heavy, super accurate weapon with low recoil, no wind, and a lot of luck, I shot ONE group that MIGHT have been as good as one you shot with a freaking magnum! Russ | |||

|

One of Us |

Uh-oh, well I didn't want to make you feel bad. You will like the RUM case. I have a 338 RUM and with a custom barrel they can be real shooters. The headspace on my 338RUM is .0015" which is very small. My magazine in the action I used was minimal so in order to use it I had to have it chambered with a very short throat though. It means I can not load to manual maxes. If the recoil is a little too much even with your muzzle brake then it is a fairly simple matter to install a recoil compensator in the stock, either mercury or mechanical. Anyway, welcome to the forum. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Headspace and Bullet Seating?????

Headspace and Bullet Seating?????

Visit our on-line store for AR Memorabilia