The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  UNIVERSAL RECEIVER

UNIVERSAL RECEIVERGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

It absolutely is not. I've visited the FBI lab at Quantico many times over the years and consider it to be a first class operation. Agent Buford Boone is up to his eyeballs in the testing there and I consider him to be not only very competent, but a trusted personal friend. KenO As it was explained to me many years ago, "I feel sorry for those who think ballistics is an exact science. They just don't understand the problems." | |||

|

| One of Us |

Chamber cast, internal mic, or if you are lazy, measuring a fired case and adding a fudge factor to allow for springback. Bear in mind that normally we are talking about measuring a taper, both inside and out, so perfection is not obtainable. That said, it doesn't seem to be a huge problem.

As discussed many times on this forum, you don't, at least in the scientific sense of the word "calibrate." You can and should do some sanity checks by firing well documented loads over a chronograph and verifying that the pressure/velocity relationship seems reasonable. Regarding your friend Denton's claim that strain gages do not need to be calibrated, he is correct as far as measuring strain goes, assuming a good glue job. Where you need calibration is to verify the glue job, the setup (inputing all the right numbers), the calibration of the electrical components, etc.. Murphy's Law always applies, so you can't be too careful.

I don't recommend applying a strain gage to an expensive custom rifle. But if cosmetics are an issue, it is sometimes possible to place the gage on the bottom of the barrel. Myself, I am gravitating to a collection of "test mules" that are used only for pressure testing.

There are too many variables to give a pat answer. Some guns and cartridges lend themselves to the use of a strain gage more than others, and then there is Murphy's law. My personal take is that the gage is best used as a measure of RELATIVE pressure, i.e., comparing load "A" to load "B" as tested in the same gun on the same day.

Last I heard, Charlie had blown at least 4 barrels, yet he hasn't published any specific data -- no loads, no pressure trace data. Until he publishes his data and it is duplicated by others, he will not be taken seriously. This is not intended as an insult to Mr. Sisk. It's just the way science works. I haven't been able to do any further experiments myself as I have taken a sabbatical from shooting while I am building a house. | |||

|

| One of Us |

Among my list of good intentions is writing a book about all the mistakes I've made. I didn't expect to write it in a chat room, but Hot Core has outlined topics for several chapters.

Measure outside diameter at gage location with a dial caliper. With fired case chambered, insert cleaning rod and mark muzzle. Hold marked rod along gun, place fired case over tip of rod, measure outside diameter of case at gage location. It's close enough to inside chamber diameter.

There is no known way to do an after-the-fact calibration (Even with SAAMI Reference Ammo). Consider the whole installation process to be similar to bore-sighting. You can be sloppy and maybe get it within a few feet at 100 yards, or you can do it properly and be with a couple of feet at 1000 yards.

You can't protect the bluing where the strain gage is applied. If you install the gage properly you will clean down to the bare metal. That's a test barrel you're working on; not a fine firearm.

If a gage is installed on a hunting rifle, I suggest putting it on the bottom of the barrel so that it is hidden. Before hunting, cut the wires an inch or two from the gage. Resolder a new cable next time you want to test pressure.

You've got it! That's much better than thinking you are at 50K and actually be exceeding 75K.

In my opinion, consider it verified.

I've never seen it happen and therefore can't comment. KenO As it was explained to me many years ago, "I feel sorry for those who think ballistics is an exact science. They just don't understand the problems." | |||

|

| One of Us |

popenmann, Had I seen your reply to Hot Core first, I could have saved a lot of key strokes. We see it the same way. KenO As it was explained to me many years ago, "I feel sorry for those who think ballistics is an exact science. They just don't understand the problems." | |||

|

| one of us |

Mr. Oehler, I have nothing to contribute, but want to offer a very sincere "thank you" for taking the time to answer questions. Dutch. Life's too short to hunt with an ugly dog. | |||

|

| one of us |

I too have to give a heartfelt hat tip to Mr. Oehler. Many fine, knowledgeable people on this board have argued with HotCore over this subject with little success. Now we see if it is possible for an old dog to learn new tricks... LawnDart, IIRC we had a former Nosler engineer stating publicly here a while back that they were transitioning to strain gauges for their load development. That's at least one confirmed major lab using SGS for published data. I suspect there are more...simple economics and the data IS good enough for our purposes. -CDH, heading back to the sidelines Believe nothing, no matter where you read it, or who said it, unless it agrees with your own reason and your own common sense. | |||

|

| one of us |

I'll quote Terry Bradshaw - "Now that's Funeeee!!!" | |||

|

| one of us |

From my first-hand experience with Mistakes, they seem to temper a real mans resolve. Dr. Oehler, I am really disappointed with that, or perhaps I'm just misunderstanding. If the SGS applied to a firearm can't be calibrated, how is it possible to have any confidence in the data provided by the M43? Is a user supposed to simply "hope" the ole variable Fudge Factor was correct? | |||

|

| one of us |

I can think of ways to calibrate an Encore barrel's strain gauge installation, so long as the gauge is mounted over the case mouth (which would lower its sensitivity some). Your typical bolt gun I cannot. However, for most people, factory ammo should provide safe pressures, and the indicated strain from these can then be used as a limit. Test several different bullet weights in cartridges from as many makers as you can get your hands on and find what's the top strain produced. Use that as your limit in developing handloads. You don't need to convert to pressure or strain; volts off the bridge circuit is enough. One problem: if your gauge isn't attached well, you might get inconsistent readings. This works for octagon barrels, chambers near the receiver (well, usually), etc. It doesn't help if you have an old gun for which no reliable factory ammo exists. I believe the makers of all the commercial strain gauge systems recommend this procedure. Also, don't neglect the chonograph. If the velocities are too good to be true, then the indicated pressures (or strains or voltages) are likely to be also. | |||

|

| one of us |

Why yes indeed, here is one for the old Dogs to chew on

That sound you hear off in the distance is, as one old poster mentioned many, many, MANY times, an entire Group of dentonites being Blown-clean-out-of-the-water! I take no "great" pleasure in you all being proven Totally WRONG - AGAIN! | |||

|

| one of us |

Hi CDH, I will use strain gauges for all my development work because as you note, it is fast, accurate and economical. Once I start producing commercial ammunition however, is when I will use the SAAMI/CIP/NATO procedures for monitoring production runs. Offereing SAAMI lab services is just a way to pay for some of the equipment. Half of the reason for going the expensive route is for liability concerns; the other half is economic. If I ever want to sell ammunition to the military, it will need a NATO approved pedigree. To sell any ammunition in Europe requires (by law) close adherence to CIP procedures. I hope that strain gauge technology will be accepted for primary pressure work by SAAMI and so on over the next several years. This is a very conservative business.  | |||

|

| one of us |

Dr. Oehler must have been called away on some pressing business(or the grandkids), because I feel sure he would not just leave us hanging. The method mentioned by "asdf" will certainly work to provide a level of Pressure where the reloader should STOP adding Powder with an HSGS. Since however this method uses an Unknown Pressure to set that Limit, it certainly does not perform a System Calibration. It simply establishes an Upper Limit at the numbers indicated by the HSGS – 25Kpsi, 80Kpsi or wherever the HSGS happens to indicate. The serious problem seems to be when people believe the HSGS is actually Calibrated(with an Unknown) and are mis-lead into believing the Pressure Numbers provided by the HSGS are Accurate. Some users then erroneously decide if the HSGS read 44Kpsi, that the Factory Ammo must just be held low and it is SAFE to keep dumping in Powder. You see these kinds of posts on the net every day, so we all know many of the HSGS users really don’t understand what they are doing. Thus it appears that any Pressure the HSGS(M43, Pressure Trace, whatever) provides is of an Unknown Accuracy and has a great potential to mislead some people. Now..., where have we heard that before. Good Hunting and clean 1-shot Kills. | |||

|

| one of us |

No, it does not provide a calibration. It won't even guarentee a safe pressure! Even with factory ammo, your gun can be developing pressures beyond industry specs, due to a badly eroded throat, non-conformant chamber, etc. For that reason, you should check fps with a chronograph, and you should also (if possible) calculate a pressure to see if all is reasonable. (Some chamber configurations will not allow a simple calculation of pressure.) | |||

|

one of us |

The potential to mislead? Maybe. I wounldn`t be suprised some don`t quite understand what they are measuring, but unknown accuracy? The unit may show PSI as the unit of measure, and that may or may not be the proper term, but it is repetably accurate to a pretty high degree. It definatly has a higher resolution of pressures produced then anything we have had before. A ruler may or may not indicate a true foot but it can still be a very accurate measure when used to compare two lenghts. Actual pressure measured is only true though in the rifle chamber it was measured in, at the temp, humidity, ect present at the time of testing and will change in the next firearm a round out of the same box/lot is fired in. As long as we lay out a baseline we can believe to be representative of max in the rifle we are useing and accuratly measure the relationship of other loads to the baseline with a degree of certainty I think we can say we are getting some valuable use from what ever system we use. The more repetable in reading to the same pressures we can get, the better the system for our purpose. Good to see you are still argueing this. You tend to get some interesting and informative discussion going on the subject with some much much more knowledgable people then I. Reguardless if we agree or not, I am learning. I think... Oh well, we`ve agrued this in this past....  Suprised to see you haven`t tried selling pressure ring measurement as a "better" measure again this time though Suprised to see you haven`t tried selling pressure ring measurement as a "better" measure again this time though ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

| One of Us |

Don't mean to leave anyone hanging. It's just my nature to lurk more and post less.

It's quite true that some folks can be misled. In my opinion, many more reloaders are misled by pressure numbers mentioned without benefit of any measurement than are misled by a properly used strain gage system. Some thirty years ago I mouthed off to a Remington engineer that I thought I had a reasonable "feel" for pressure if I could feel the opening of the bolt on my rifle and feel the primer seating in the reloaded case. I had been using the same load in my '06 (Rem 721) for approximately fifteen years at that time, and knew that it delivered honest factory velocities. We put a few rounds through the Universal Receiver with a conformal transducer and the pressures were approximately 10% above maximum average pressure. His comment was a simple, "It's a good thing you're shooting these in a Remington 721; they are a little hot." That old 721 has been now been modified to include a strain gage and a copper crusher set-up, and has been replaced with a Rem 700 as my "go-to rifle". I'm still loading the same load and have measured the pressures many times. With a strain gage in either the 721 or 700, I consistently see pressures very near factory max. In the Universal Receiver, the same load will consistently show 10% over maximum. No big surprise because I considered it a max load when I was forty years less cautious. Surely the cumulative effects of firing this load must cause cases to grow, pressure rings to expand, and primer pockets to loosen after a few firings. The load was initially worked up in Lake City 57 cases. In my inexperience, I bought a Lee Precision reloading set and "uniformed" the case necks with their little boring tool, trimmed cases to length, and even "uniformed" the flash holes. Those 100 cases have never again been full-length resized and have never been trimmed again. For practical purposes, they have worn out two barrels. I neck size and deprime, reprime, charge, and seat with hand tools. Primers are still snug, and I don't recall ever discarding a case. (Yes, I have lost a few while hunting.) I tell this story simply to illustrate that I have no illusions of knowing pressure from observing cases, even with a repeated "over maximum" load. Others might be able to read pressure from the brass, but I can't. Hot Core has expressed displeasure that there is no "After Installation" calibration of the strain gage system. To the best of my knowledge, this is true for ALL methods of chamber pressure measurement. I challenge anyone to provide a clean calibration procedure for any measure of chamber pressure in a rifle. It's much easier to throw stones and cast doubts that it is to prove truth without possible exception. KenO As it was explained to me many years ago, "I feel sorry for those who think ballistics is an exact science. They just don't understand the problems." | |||

|

| one of us |

Dr Oehler "Calibrating" pressure, volume and force to external standards is relitivly easy. However with firearms we throw in one inconvient factor, and that is time. Just as a Db meter can tell you what level a sustained sound is at but can't accuratly measure what the peak sound pulse of a rifle shot is, a tensil testing machine can't measure what the impact bending/breakage force is (tensil testing normaly takes place in the .010 to .250" inch per minute range vs a stamping press that impacts in the 1000"/min range). There are limitations to just how fast the entire system can operate, beyond those limits what we get are repeatable results that can only give us a "close aproxamation", but not a truely "accurate" number. "Close enough and repeatable" is all anyone can expect, but some people are want to demand those thing that are simply not obtainable (at least with the technoligy/equipment that we have today). | |||

|

| one of us |

I'm sure it would not mislead "asdf", Ol` Joe, Dr. Oehler, LawnDart, Bob338, me and even a good many others I see post here like VapoDog, Reloader, Gerard, Woods, etc. On the other hand, we all know there are those out there who really do not have a clue as to how the HSGS actually work. Just to save time, I can lump them all under the "dentonite" heading. They've also been DUPED(PT Barnumed, dentoned, fooled) into believing there is a conversion from CUP to PSI. And there is a HUGE third group of folks who are inbetween the two groups. They are composed of every experience and knowledge level, but have the potential to be mislead by well intentioned, but incomplete details about how all these things "REALLY" function. Hopefully the excellent input by Dr. Oehler will help them understand the HSGSes are "Test Instruments", just as he said. I completely agree with your thoughts. Actually I was thinking in the context of seeing the statements where "Young` Moe" asks for a Load and says, "I know this cartridge has a SAAMI MAX of 62.0KCUP from my Manual, but I can't measure CUP. Can someone give me a good HOT Load?"(We see it all the time.) Then someone with a HSGS will respond with something like, "I have a great conversion factor which changes CUP to PSI. Then I use fully Match Prepped, weight sorted Nosler cases, Fed-215M Primers, 62.3gr of XX Powder, 180gr Accubond Bullets, seated to 3.3651"OCL as measured with a Stoney Point Thingy, and in my 24" barreled rifle it runs 3059.8fps at ONLY 57,984psi." Here is where the Beginners/Rookies can be seriously mislead. All the information provided "gives the appearance" of being provided by a skilled, knowledgeable reloader, but the sad truth is the Load is based on False Conversion Data and a non-calibrated HSGS. It may be SAFE in Young `Moe's rifle, or it might not be - that is the problem. And neither the person giving the Load or Young ` Joe knows it. Obviously we agree. As long as we have people like Dr. Oehler providing information to the Board, we are all better for it. Even when we end up "agreeing", it is not wasted on the Beginners/Rookies. I've intentionally avoided it, because it would not help sales of any HSGS, when a time-proven, totally-reliable, constantly-repeatable, industry-respected, Pressure Detection Method, which has been in use for over 100 years, takes 20min to learn and only costs $30 - works so well. Good ole Pressure Ring Expansion(PRE). 1. Do you need to Haphazardly measure a chamber? Advantage - PRE or HSGS? 2. Do you need a $10 throw away Strain Gauge? Advantage - PRE or HSGS? 3. Do you need to glue anything to your rifle? Advantage - PRE or HSGS? 4. Do you need wires in the way to fumble over? Advantage - PRE or HSGS? 5. Do you need a computer to make it function? Advantage - PRE or HSGS? 6. Do you need a long System Set-Up at the Range? Advantage - PRE or HSGS? 7. Do you take Data directly from the Case or third-hand through a Strain Gauge? Advantage - PRE or HSGS? 8. Do you spend more than $30 for the Pressure Detection Method? Advantage - PRE or HSGS? 9. Does it take more than 20min to learn to operate? Advantage - PRE or HSGS? 10. Is it possible to Calibrate the Measuring Device to a Known Standard? Advantage - PRE or HSGS? 11. Does it take a truck to carry, or is it similar in size to a box of cartridges? Advantage - PRE or HSGS? 12. Do you establish a Comparative Benchmark Standard using Factory Ammo? Advantage - same-E-same 13. Do the Test Cases get to a point(work hardening) that they can mislead the user? Advantage - HSGS! 14. Does either Method allow the user to quote misleading, inaccurate, Pressure in Kpsi? Advantage - PRE or HSGS? Is there an Advantage to one of the above methods over the other? Just for you Ol` Joe. | |||

|

| one of us |

Hey guys, I started this thread to ask a few questions. The answers will help me to make safe ammunition for commercial sale. I'm also hoping to be able to offer a service that will be helpful to the reloading community, again, in the interests of safety. Dr. Ken Oehler, one of the best ballisticians of this (and any) era, has kindly shared some of his time and expertise with us. Hot Core, as a courtesy, would you please take the great debate over to a new thread, and allow this one to go back to its original purpose? I would appreciate this greatly. Thank you, LD  | |||

|

One of Us |

Just a wild guess, but that might be our Famous But Incompetent friends. [/QUOTE] No it was probably the Fumbling Bunch of Idiots, but you were close!  Member NRA, SCI- Life #358 28+ years now! DRSS, double owner-shooter since 1983, O/U .30-06 Browning Continental set. | |||

|

| one of us |

Thanks for correcting me on that Ken. I was thinking about another department.  | |||

|

| one of us |

Didn't realize it would bother you, or I would have waited for a different thread. Best of luck with the Ammo Business. | |||

|

one of us |

Ken, What are your thoughts of useing a set up similar to CIP where the gage is placed at the mouth of the case not a point midway in the case body and thus eliminating the need to measure the case wall, and chamber? You would have a fairly accurate idea of bore size based on caliber of the cartridge, or would the rifleing/throating screw up this figure? Elimination of this and the case wall thickness and fudge factor in how much variation there is between the expanded case wall measured and the true chamber diameter would surely add to the accuracy of the final reading. CIP standards are available and seem to work for the rest of the world if desired to compare to. Thanks for taking time to educate us on strain systems. I tend to side with HC there may be a myth or two to be exposed on exactly what we see with them that you are exposing. I do agree they are the best bet we -the hobby loader and possibly some in industry- have to accuratly judge our loads however. ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

| One of Us |

Ol'Joe Locating the strain gage over the neck, throat, or bore area would indeed make measurement of the inside diameter easier and more accurate. On the other hand, this location introduces some extra complications. 1. The ratio of outside to inside diameters is larger, and there is significantly less strain on the outside to be measured. 2. There is often significant taper on the outside of the barrel at this point. 3. The pressure at this point is not apparent until the bullet moves past. 4. The pressure at this point is lower than at midcase or the propellant gases wouldn't be flowing to keep up with the bullet. 5. Venturi effects of the moving gas would also tend to make the pressure appear lower. 6. I'm not sure just what CIP is doing at the present, but they were measuring at midcase thru a drilled hole. That is different than casemouth. My life has been a series of compromises. I just make my best call and go. My thanks to all of you for the kind remarks regarding my posts. Lawndart even honors me with the title of ballistician. I must renounce that title and claim to be only an engineer who has spent the last forty years trying to measure velocity, pressure, and target accuracy. I've known several great ballisticians, but I can't honestly claim the title. It's back to lurking for a while. KenO As it was explained to me many years ago, "I feel sorry for those who think ballistics is an exact science. They just don't understand the problems." | |||

|

| one of us |

Thanks Hot Core, Sorry if I sounded too crabby. I shouldn't post at the end of a long shift. Thanks for all you insights Dr. Oehler. Assuming you are indeed strictly an engineer (hmmmm, no), your work has made many things possible. Especially all those letters to the ammo companies that have said, "hey I thought you guys advertised a velocity of XXXX fps; what gives?" After talking with some universal receiver manufacturers, PCB (makers of transducers, charge amplifiers, in line amplifiers, low noise cables, blasting caps [just kidding], etc.) and barrel makers; it looks like lab instumentation alone will run $45,000.00 - $60,000.00. Anybody want to buy a nice little medical clinic??  | |||

|

| one of us |

I must have missed that part. Perhaps that is why everyone refers to me as amiable old Hot Core, but I'll pass on taking a Poll on it. | |||

|

| One of Us |

Returning to the "second pressure pulse" As I recall Charlie Fisk reported that he was trying to get a detonation with reduced charges of slow powder. It may be possible that the Second pulse is related to that. My problem with muzzle pressure effects is that the gage is at the breech, and it looks like the bullet has left the barrel. It was also reported that the pulse moved "back" as the barrel was shortened. It always looked like the pulse was really barrel bending moment. This would mean that a gage on the side of the barrel would read differenly than a gage on the top. Or a barrel clamped in a vise forward of the gage would not see the moment. Can anyone give insight to these questions?. Thanks! | |||

|

one of us |

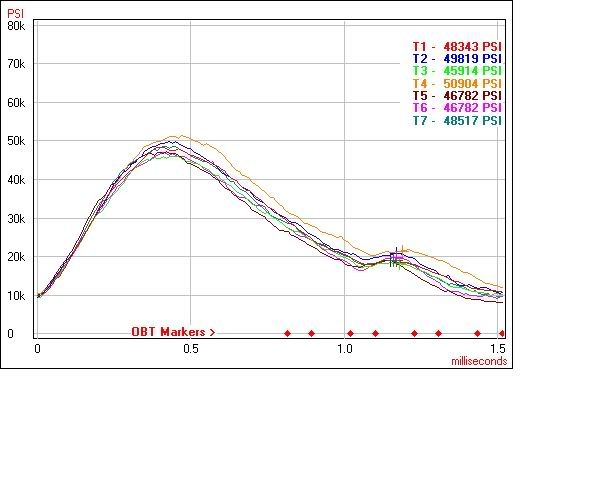

Hawkins Charlie was useing slow powders but he wasn`t useing low charges. The problem occured when he saw "secondary" pressure rises at the muzzle or down the pressure slope while working up a load. He decided he was with in book charges and decided to ignore the secondary rise as a fluke and added more powder as the primary pressure peak and velocities were below max for that load. As he added powder the secondary rise increased and at some point it blew the muzzle brake off the rifle barrel. He reported he tried it with a diferent rifle and slow powder and found the same spike. John Barness, I believe, worked with him on this in a couple different rifles and found they could reproduce the secondary rises at will with the right combinations of slow powders and, as I recall "light for caliber" bullets such as 150grs in 30 cal. Denton also reported finding these, and I have seen evidence of them while useing my Pressure Trace with some load combinations, but not to the extent Charlie claimed. This is a favorite 6.5x55 load of mine -47.5gr of R22 with a 129gr Hornady- but it shows signs of the spike at the muzzle and won`t be raised.  ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

| One of Us |

Do you know when the bullet leaves the muzzle?. Thanks! | |||

|

| one of us |

I had some curves that were done on a barrel that had four or five gauges down its length. They might be buried in the storage unit. On the graph above, the bullet exits where the little cross appears on the line (~1.4ms). LD  | |||

|

one of us |

Lawndart, can you post a copy of the graph with the multiple gages? I`d be interested in seeing how the various points on the barrel relate to the main graph attached to the chamber. Did they seem to mirror each other or was there a difference in the pressures they reported? Hawkins, the exit points are as Lawndart said. They are represented by the small tic`s that appears near the peak of the second pressure rise. This is if the unit is calculating them accuratly. ------------------------------------ The trouble with the Internet is that it's replacing masturbation as a leisure activity. ~Patrick Murray "Why shouldn`t truth be stranger then fiction? Fiction after all has to make sense." (Samual Clemens) "Saepe errans, numquam dubitans --Frequently in error, never in doubt". | |||

|

| One of Us |

That is very interesting. How does the unit calculate bullet exit with a gage located at the breech. From the curves the pressure hasn't bebun to fall for the second time. Thanks for the answers, these questions have bugged me for quite a while. Take Care! | |||

|

| one of us |

I'll hazard a guess. They make an estimate using the method Powley once described; see the posts by lawndart and myself, in this thread, back on March 9. | |||

|

| one of us |

The Pressure Trace software is designed to use the strain gauge in concert with their chronograph. Basicaly, when you input all your parameters and pull the trigger, a bunch of little squirrels in the algorhythm throw around a bunch of "queertrons" from one end of the chip to the other, and calculate the exit point. Just kidding, but that is the basic idea. That and the math as described by asdf I'll try and dig out that set of tracings. They are buried under a wash machine and a couple of river kayaks. I'm not sure that anyone has definitively figured out the cause of those secondary peaks. Many theories abound....... The thing I try to remind myself of is that the strain gauge measures strain; I sometimes wonder if that peak is an harmonic artifact. In the absence of exploding barrels, gross velocity excursions or anyone paying me to cipher out an answer I don't lose sleep......  | |||

|

| One of Us |

Lawndart; Yes that has been my opinion from the begining. A single gage at the breech will not only measure Hoop Strain, but Bending Moment as well. As the rifle recoils into the bent stock the receiver recoils upward. The receiver lifts the barrel up making the barrel bend down for the first mode. Vaugh's "Rifle Accuracy Facts" shows a measured bending moment identical to the "muzzle pressure pulse". That is why I asked if anyone hah clamped the barrel down forward of the receiver. Thanks for the reply. Take Care! | |||

|

| one of us |

This was taken from the RSI web site, which I should have checked before my last post. Given this quote, it seems safe to say they are doing something similar to what Powley wrote about. | |||

|

| one of us |

What's more dangerous than one of us with an equation? Nothing in the world  | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia