The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  P-FLR with Redding bushing die

P-FLR with Redding bushing dieGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Here is my question. I have a Redding Type S bushing full length resizing die. I acquired this plus the Neck and body die when I made a gun deal a while back. I was told to use the neck and body die to make my loads with. After reading on here about the P-FLR I want to go that route. Keep in mind I already own the Redding die. Can I P-FLR using the bushing die? And can I also do this without using the expander ball? The die came with the other tip so I have it. I have just read a lot of views about dragging the expander back through the neck and wanted to eliminate using it. I have very little experience with these dies so I am all ears on their use and my ideas in general. All help, ideas and tips are greatly appreciated! WS | ||

|

One of Us |

The Redding Bushing Dies work best without the expander ball and in conjunction with outside neck turning. The reason is that the bushing sizes the outside of the neck and pushes all the variances in neck thickness to the inside where they will effect bullet grip and release. If you use the expander ball you might as well be using a FL die, would be a lot cheaper. If you neck turn your brass to a consistant thickness and then use the bushing then you will get consistant inside and outside neck diameter. You can PFLR in a 2 step process with a neck sizer and body die. What kind of neck sizer do you have? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Thanks Woods! The neck sizer is also a Redding bushing die. The brass I am using is lapua. The cal. is 6.5x284. I wasn't going to turn the necks and am in hopes with using lapua I won't have to. I do see what you are saying though so maybe I am fooling myself with thinking I won't have to. Is the finished case- bullet combo going to be as concentric using the two dies as it would be if I would do it with one? WS | |||

|

One of Us |

If you are resizing for a 6.5x284 (probably Norma version right?) then your chamber neck is probably .295" or .296" right? So you need to monitor your neck thickness in order to have the recommended .003" clearance around a loaded round neck. If your Lapua brass is perfectly consistant in the neck thickness and is ..... say .014" then the math would be: .264" (caliber)+.014"(one side)+.014"(other side)+.003"=.295" But if your brass is thicker then you need to turn it. What kind of outside neck turner do you have? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

It is a 6.5 x 284 Winchester, not the 6.5x284 Norma It has a .297 neck,(engraved on the barrel). I don't have an outside neck turner. Guess I should get one.I also don't have a case neck micrometer or a concentricity gauge, just so you know. WS | |||

|

One of Us |

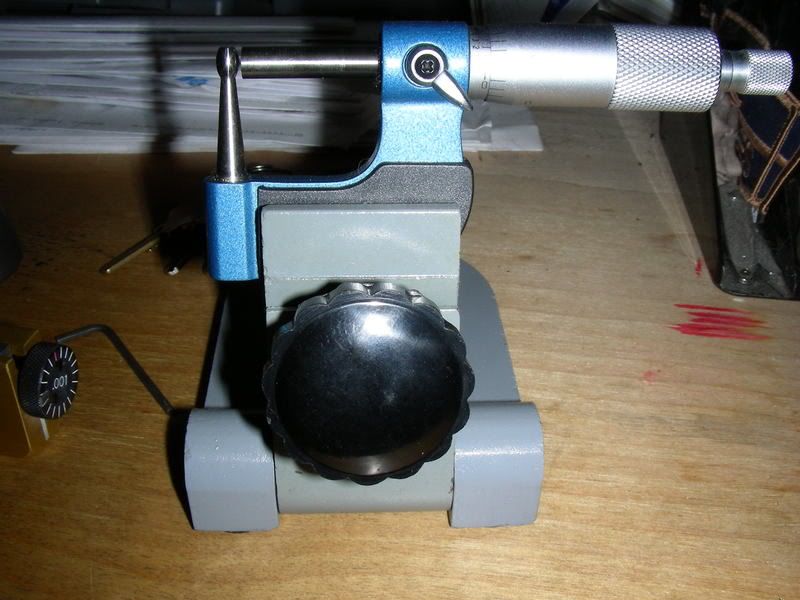

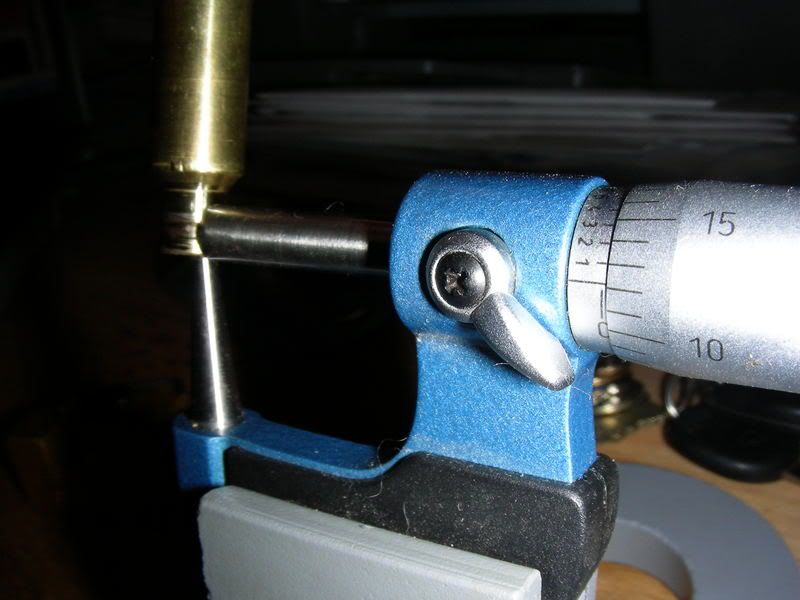

Well I do a lot of turning for tight necked custom chambers and I would recommend the following: A fairly inexpensive ball vernier micrometer and a micrometer stand  It makes it much easier and more exact to measure the case neck thickness at all points on the neck  then you need an outside neck turner. I recommend the Forster Hand Held Outside Neck Turner It is not the most expensive but will get the job done. I like the wide blade for a smooth cut  and later if you develop do-nuts you can set your brass up so the Forster neck reamer will get rid of them  with a .297" neck you will need your brass to be: .297"-.003"-.264=.030"/2=.015" each side. Now I don't know about Lapua brass but Remington brass for my 6.5 rem mag varies from .015" to .017" and my neck is .293" so I have to turn them down to .013". Of course there are other ways to skin this cat but this works for me. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Woods, Forster says to use the reamer before sizing. How does the reamer find the donut? Doesn't the donut get smaller with sizing? I have lots of confusion on how to do it. TIA | |||

|

One of Us |

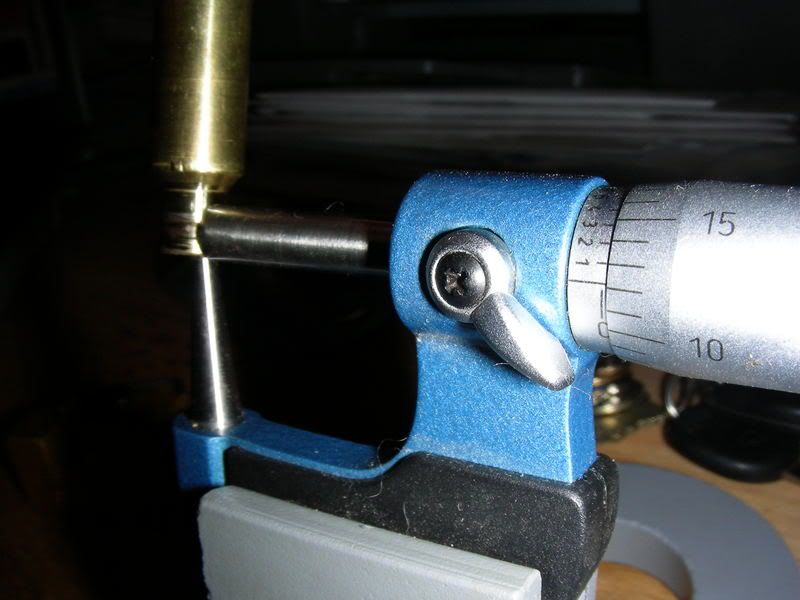

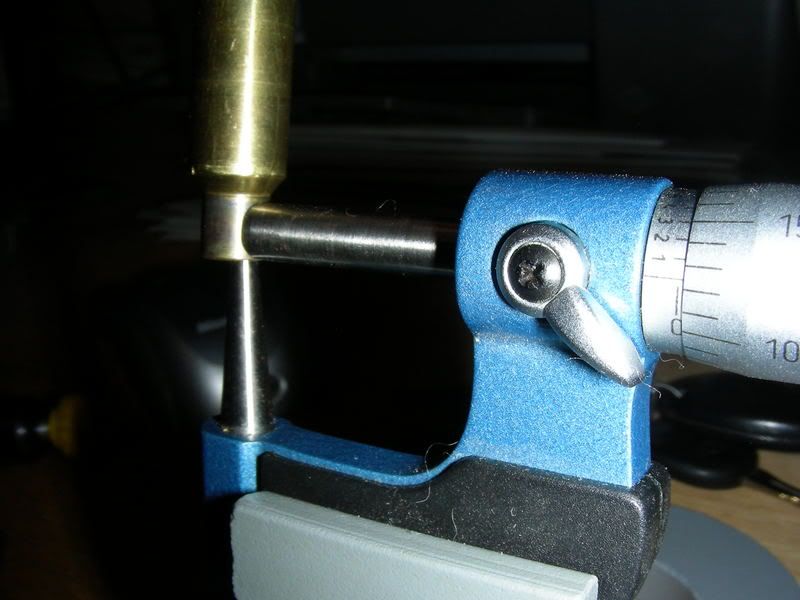

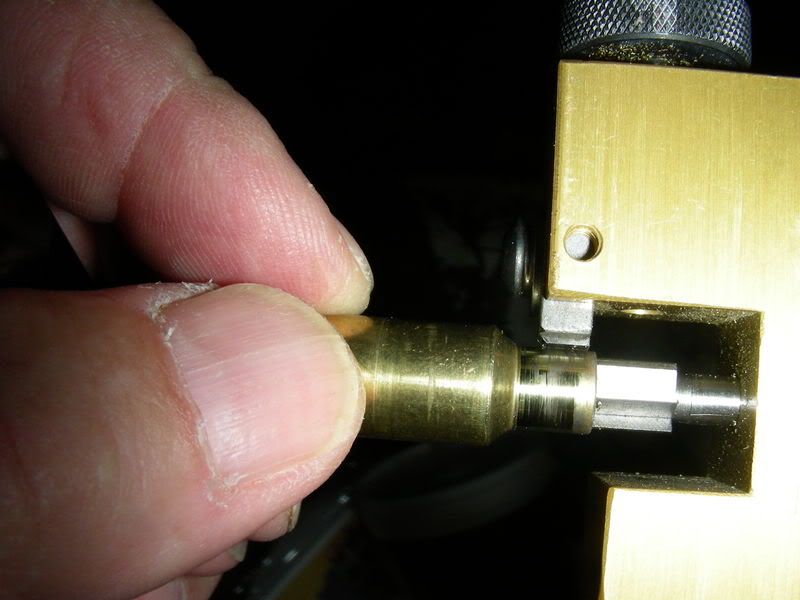

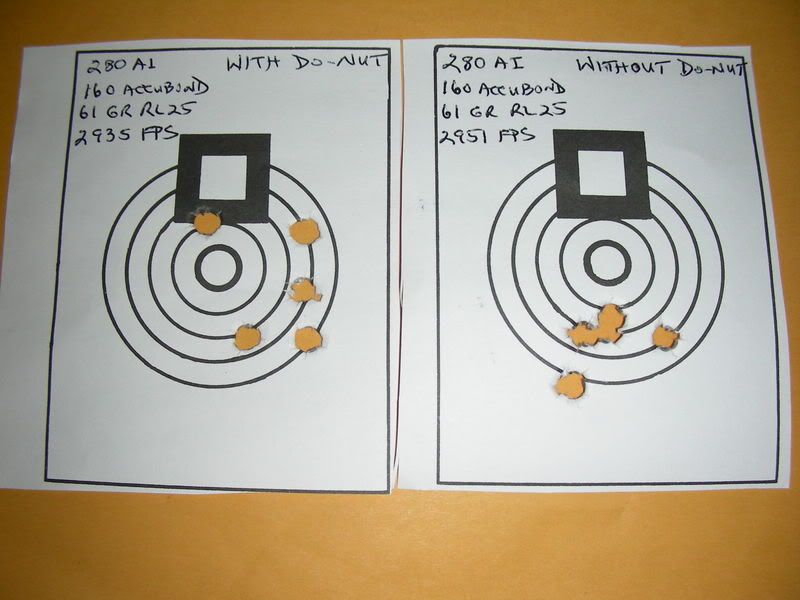

The reamer is .003" over bullet diameter so if you set your brass up with .003" neck clearance in a tight enough chamber, the neck brass will expand with firing and the inside diameter will be .003" above bullet diameter. Perfect for the reamer. For instance in my 280AI the neck is actually .312". I turn my necks to .0125" and that leaves .003" neck clearance around the loaded neck. After firing the outside diameter is .312" and the inside diameter is .287". So I use the reamer to ream the inside and clean up the outside of the necks at the same time. Before reaming with neck thickness at .0125"  then I ream and clean up the outside  to get a reamed and outside turned neck thickness of .012"  I do develop do-nuts in the 280AI and the reamer will take them right out. You have to realize about do-nuts that the only way to detect them is by inserting a bullet in a fired case. If the bullet stops at the neck/shoulder junction then you have a do-nut. You can't measure it and you can't feel it with a paper clip or anything else. If you have a factory chamber with a lot of neck clearance then you may have a do-nut but it will not stop the bullet and it will not matter. If you have a do-nut that stops bullet movement then resizing will not matter because the do-nut will still be squeezing the bullet even though you have seated past it. And there is no way to tell if the do-nut is still there after sizing because, remember, the only way to detect one is by inserting the bullet down to it and you can't do that after sizing. Removing do-nuts can make a difference  ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Wow! Thanks for all your time and effort trying to help me! It looks like I have some information to digest. I will start looking for the equipment I need to get and then I will give it a whirl.I had been looking at the NECO Concentricity and wall thickness gauge. Would this also be an option? Don't be surprised if I come knocking on you door down the road. Again Thanks, Mr. Woods! WS | |||

|

One of Us |

Don't know about the NECO, but the RCBS concentricity gauge will measure neck thickness also but it only measures in one spot just in from the mouth  and that is not as good as a micrometer on a stand. However if you are going to get into chasing concentricity also then the concentricity gauges like that will serve a dual purpose. The NECO is expensive but may well be the best. Now there are concentricity gauges where you can push the bullet and fix runout so you should investigate that first. I will look for the link. You wouldn't want to spend that much money on a NECO and then see a gauge that would have the added purpose of fixing your runout. These pics are all in my photobucket so it is no problem posting. Ask away, sometimes an off the wall question can lead me in new directions and that's what floats my boat. Maybe even find a new "thingy" to irritate Hot Core with! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Ok, here is the link to a new tool from Hornady that looks like it will also fix runout. Don't know how well it works  In thinking about your question about sizing without the expander in the bushing die, one question: What size bushing are you using? It should be stamped right in the top of the bushing or you can take out the expander stem and size a neck and then measure the outside diameter of the neck with a caliper. Certainly you can size the neck without the expander and push the shoulder back with the die. Bullet grip will vary depending on the neck thickness of the brass and the size of the bushing. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

You can use the Body die to bump the shoulder back to where you /your rifle needs it to be, partial full length resizing the body and shoulder only in this step. then with the bushing neck sizing die size the neck as you need. Or with the full length bushing die you can do both operations at the same time. I typically set my dies to bump the shoulder back .002" from the fired case dimension. A Mo's gage or an RCBS precision mic case gage will give you the fired case head to datum measurement. Set your die to move the shoulder back .002" from the fired case dimension. Then select a bushing to give you the bullet grip you select. Usually .001 to .002" less than the loaded round neck diameter. Neck turning will make your loads more concentric. But this is not needed unless you are shooting a very accurate rifle and you can drive the rifle to it's potential(or close to it). I hope this doesn't confuse you further. muck | |||

|

| One of Us |

the idea of reaming is to avoid making a donut in the first place. Of course, if you are working with cheaper brass that has a lot of varience in neck wall thickness and roundness, it's not going to be as effective. I don't know why anyone shooing a factory barrel would want to partial resize the neck when he has a neck sizer. You partial either because you don't have a neck die, or if you're shootin a tight necked BR chambber you partial WITH a bushing type neck die to help center the cartridge. If you have the 3 dies mentioned and the proper bushings for your chamber, it sounds like you're all set up. There is some slight learning to be done to use the tools properly. YOu might start here:http://www.redding-reloading.com/techlinepages/techline.html If the enemy is in range, so are you. - Infantry manual | |||

|

One of Us |

amamnn He is not partial neck sizing he is partial full length resizing. Reaming is to get rid of the do-nut after it develops. I can see no way that it will prevent the do-nut from developing. The do-nut is from brass flowing along the shoulder slope and protruding into the neck opening and is only detectable on tight necked chambers with little neck expansion. There is no way that taking a little brass off the inside of the neck will prevent do-nuts. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

The bushings I have are .292 and .293 I loaded 20 new lapua cases and the outside neck diameter is .293.5 Also that Hornady LNL Ammo Concentricity Gauge looks pretty good. I wonder how long before they will be available.Everyplace I checked said back order only. WS | |||

|

One of Us |

So if you used the .292" bushing and your loaded outside .2935" then you would have a .0015" bullet grip and with a neck of .297" there would be .0035" clearance around a loaded neck in your chamber. Oh, and your brass should be just under .015" thick. Good chamber. You could get a .291" bushing and increase bullet grip to .0025" which would hold your bullet better but might lead to more runout from seating the bullet. If you leave the light bullet grip then you might have trouble with bullet movement but probably not. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

If I push pin gauges into a sized .223 case neck, the .222" and .221" will slip fit in the neck, but they both stop at the base of the neck. If I try to seat a bullet, the effort goes up when the bullet reaches the base of the neck. | |||

|

One of Us |

Haven't ever used pin gauges. Then let me ask, does this case have signs of a do-nut before sizing, either with the pin gauges or by inserting a bullet down the unsized neck? And how do you know the seating force increases at the base of the neck? Do you have some kind of gauge or are you gauging by feel? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I am running on feel. The 223 brass has no doughnut when it comes out of the machine gun. It does have one when it comes out of the FL sizer. I need to FL size to get it to fit in my Ruger #1 .223. Subsequent sizings can be with the Lee collet die. Pin gauges are a must have for fanatics Get .251" to .500" set and and get the .061" to .250" set. http://www.use-enco.com/CGI/IN...15208&PMAKA=616-8130 http://www.use-enco.com/CGI/IN...15206&PMAKA=616-8125 You can wait for them to go on sale at Enco, or you can buy at CDCO, where they are already dirt cheap. CDCO sounds like a Chinese immigrant selling tools out of his apartment with a baby in the background, but the tools show up, are good, and cheap. http://www.cdcotools.com/index.php If I can get off the dime this morning, I will make another Forster trim pilot, this one will have a half moon cut for doughnut trimming. | |||

|

One of Us |

Well, for $132.00 per set I'll just have to have you run interference for me whilst I pose the questions! If you don't have a do-nut before sizing but have an obstruction of some kind at the neck/shoulder junction then the sizing must be causing it. Or possibly, like you said, the do-nut that is there originally but back too far to obstruct the bullet is brought down to the new neck size upon sizing the case. I'm thinking about it. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

$55 + $33 for both sets at CDCO. Good for handloaders for measureing: a) chamber necks b) die necks c) primer pockets d) case neck inside diameter e) calibrate dial calipers before measuring a bullet diameter f) measure brass neck base doughnut g) comparing honed neck FL dies to bushings Good for gunsmithing for measuring lots of things: a) gas hole in barrel b) gas hole is a regulator c) bore size | |||

|

| One of Us |

I think you will find that all fired case necks have some constriction at the junction of the shoulder. However it may only be a few .0001. The shoulder has more spring back than the neck. Whether the constriction is just a bit of taper inside the neck or includes a doughnut may be difficult to determine. Pin gauges are very useful. I am not sure that looking for doughnuts is very useful for most rifle chamber cartridge case combinations. | |||

|

One of Us |

For $88.00 I might just have to joint the "fanatic" club. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

You may already be a reloading fanatic, you just don't have the pin gauges yet | |||

|

| One of Us |

One last thing. Just in case anyone’s eye caught the Hornady concentricity gauge that Mr. Woods so kindly posted. I talked to Mindy of Hornady today and she said it very likely wouldn’t be on the shelves of dealers until the end of February. She said you could buy it direct from them at that time but the cost would be more. Anyway just incase anyone was wondering! WS | |||

|

One of Us |

Be interesting to see if it works better than my Bersin  It does look like it would fit all calibers, unlike the Bersin. Definitely cheaper. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

http://castboolits.gunloads.co...?p=475072#post475072 Here I use pin gauges to measure and verify removal of doughnuts. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  P-FLR with Redding bushing die

P-FLR with Redding bushing die

Visit our on-line store for AR Memorabilia