The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Help a newbie with Win94, 311291, 25 gr IMR4895

Help a newbie with Win94, 311291, 25 gr IMR4895Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

like new 1977 Win model 94, with Leupold 40X test scope: 11/18/03 trip to the range: Neck sized some second hand 30-30 brass with .308 die. Charged with 25 gr of IMR4895. Seated 311291 170 gr gas checked bullet from Big Sky with .308 seater. Went to the range and got a 4 shot 2.4" group at 100m. Encouraged, I bought a Lyman M die and a Forster 30-30 die set. I went back to the range 2-8-04 with the same rifle and scope: 1) 150 gr. boat tail jacketed bullet, 10 gr. Unique, 1.5" group at 50m. At 100m, 3 of 5 rounds on the 8.5x11" paper 2) Tried 25 gr.IMR4895 with Lyman 311291 bullet from Big Sky with gas check and prepped brass with Lyman M die and seated with Forster 30-30 die to 2.58", 4" group at 100m, but only 3 shots were on the paper Where did I go wrong? It is the same rifle, scope, bag of bullets, and jug of powder. All I did was buy better dies and fire 10 rounds of jacketed bullets to sight the scope in between the two efforts. Did the M die make the neck too loose? I may have seated the bullets longer than would feed from the tube the first time, could that be it? Where did I go wrong? | ||

|

| one of us |

I'll bet the boattail bullets weren't going fast enough. That would be a pretty light load for that type of bullet and you might have gotten one stuck in the barrel. I would never use Unique with a jacketed bullet that heavy. Now, as to the cast bullets. Bullet #311291 is usually a good shooter in most M94s. Note how you loaded the first batch of ammo, the ones that worked so well. Neck sized brass that probably fit the chamber well. The "M" die shouldn't have been a problem as it's function is to make it easier to seat a lead bullet without damaging it. FWIW, I load all my 30-30 ammo using an old Lyman tong tool set up. It only neck sizes the brass. I can get away with that for about four or five reloads before I have to full length resize and anneal the necks. Also, I load my cast bullets in 30-30 to full power specs. I might have suspected bullet diameter as being part of the problem, but your first groups seemed to be OK. Check bullet diameter as they should be at least .001 to .002" larger than groove diameter. If the bullets are sized at .308", they're too small and you may have serious leading which could also be the cause of the loss of accuracy. You said that you may have seated the bullet too long for feeding from the magazine. Try seating that bullet so the nose just kisses the rifling. The bullet should still be seated deep enough in the case to feed. I find I get the best accuracy from cast bullets when they just touch the rifling or are slightly engraved. I have two molds for #311291, and I can seat them so that the nose is slightly engraved by the rifling and they will still feed in four M94s, two M64s and a Marlin 336. Accuracy is in the 1.5 to 2.0" range depending on the individual rifle. I can't say any of this is of any help, but maybe it'll give you some ideas to try. Paul B. | |||

|

| one of us |

One possible is accumulated jacket fouling in the bore after the jacketed slugs. Cast bullets like a clean bore minus gliding metal fouling-- which encourages leading and hence accuracy degrading. Good copper melter and a final polish with JB bore paste or tooth paste and your set. Then the induced runout by the new dies... hard to figure given the Q. Load the original way and check the results, being sure to use the SAME OAL and loading routine. Sometimes a mere 10 thou OAL chg drastically changes accuracy...then there and done that. Not always-- but I've traced some wide groups to that variable. | |||

|

| one of us |

Like Aladin said, I'd give that rifle bore a good cleaning in order to get rid of lead and copper, then I'd go back to the 308 dies that originally worked. After the cleaning, shoot a fouling shot and then shoot for group. One question: how much does your brass vary? If it's not all the same manufacturer, don't expect 2 MOA groups. If you plan on consistent 2 MOA groups or less, the brass needs to be the same lot number. | |||

|

| one of us |

Hi Clark- Just a few thoughts. Check your scope mounts and the scope for looseness or other problems. Were the groups stringing or round? You might have someone check your benchrest technique. I have someone else shoot my loads to check me out when things fall apart. I am not real good on the bench and others have proven it to me. The last thought is the worst. I had ( repeat- HAD) a 94 winchester that refused to shoot ANYTHING consistently.All other .30 cal. guns put it to SHAME. I have a 94 in .357 now that shoots just fine. The other one almost caused me to take up shotguns. Dale | |||

|

| one of us |

Paul B, Aladin, Junior 1942, and DE Hillyer The brass is mixed RP and Win. The bullet diameter is .309" The across the grooves diameter is .308" The bore got Shooter's choice after each trip to the range, but not between the 10 jacketed bullets and the cast bullets. I checked the scope mount and the rings while at the range [I have been stung with that a few times] I will try it without the M die. They make the neck bigger on the first entry and belled on the second. I can bell the mouth enough with a hammer and 257 case to start the bullets and leave the rest of the neck small. I can try different seating lengths. I can try more shots. | |||

|

| one of us |

>The brass is mixed RP and Win. That's probably your biggest problem. Invest in some new cases of the same brand. There's a big difference in usable case capacity between brands. In other words, some cases have more room for powder than others, so there's almost zilch possibility for decent groups. | |||

|

| one of us |

-Another ( probably goofy) thought/ How hard are those bullets? I think hard bullets don't seal the bore unless really driven hard. A softer bullet might work better. I sometmes bell with an 8MM dummy round. A case in 1 hand and the dummy in the other. Push together and "roll and wiggle". Sounds x-rated but does a fine job on thin 30-30 brass. If the brass you have in "pick-ups" from the range- you may all different kinds of neck tension- meaning a larger group. When you neck sized those 30/30's in a .308 die, you might not have pinched the neck as tight as a set for the 30/30. The difference is in the neck thickness of the 2 different cartridges. I might pick one good piece of brass and load it at the range for all my groups. That might be interesting to do, too. Another thought- push a tight patch thru your clean bore- note any tight or loose places. I had a gun once that was really tight just ahead of the chamber and really loose the rest of the way.The bullets were swaged down too small and then rattled around the rest of the way to the muzzle. Of course it shot bad until the tight spot was fixed. One more thing, drop a 311291 bullet nose first into the muzzle. Does the nose ride firmly on the lands or does it have room to "wiggle"? Wiggle= not good in my book. While you are there, check the crown for damage when you pull the bullet out. Just guessing. I would really like to know what the problem is. My 30/30 94 Win really tested me. Dale | |||

|

| one of us |

For me, the main problem I've had with tube feed guns is the magazine tube is too tight a fit, and the forearm is also tight. I fix them by taking a few thou off the receiver end of the mag tube with a file, and also relieving the forepiece where it touches the receiver. To keep it from rattling, a bit of silicone calk between the barrel and magazine does the job. I don't think 10 rounds of jacketed would have done much to foul your bore. As bad as you report it to be, I'd suspect something basic with the rifle, not your reloads. | |||

|

| one of us |

Junior1942, DE Hillyer and grumble, I will segregate brass and look for some new brass. I don't know how hard the lead is, but it has gas checks and red lubrication. here is where I got the bullets at Big Sky I have retraced my steps. The 30 short Lyman M die, for 30-30s was back ordered, and I used the 30 long that did arrive. It is meant for .308 and longer. The tool is .3065" in the long introducer stage that goes down the mouth. The short bell stage is .311" When I size the brass with 30-30 Forster die w/ no sizer ball, the neck has in inside diameter of .298". After the M die introducer has been in there, the inside of the neck has expanded to .3075" So there is .0095" difference in inside neck diameter from the first step to the second. But when I neck size with .308 dies the inside diameter is .309". Could I have gone to the range the first time with bullets that loose? If I neck size with 7.62x39 dies the inside diameter of the neck becomes .305". One obvious problem here is dementia I don't know for sure how I neck sized the brass the first time. I suppose I could retry with both possibilities. I am not averse to taking guns appart and modifying them. If I am sure of what I am doing. I have cut threads and reamed chambers on barrels of Mausers, but I have not taken the 30-30 apart. -- A society that teaches evolution as fact will breed a generation of atheists that will destroy the society. It is Darwinian. | |||

|

| one of us |

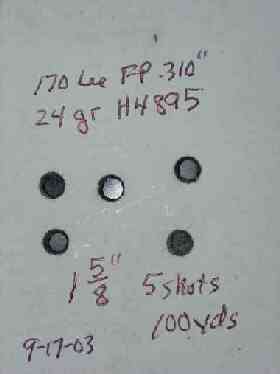

MidSouth sells 100 new 30-30 cases for about $15.00. You will soon have spent that much on bullets, powder, and primers for those reject cases. If you plan to shoot that 30-30 rifle for several more years, Sinclair sells a 500 pac of WW 30-30 cases for about $75 and they'll all be from the same lot #. Always full-length resize new cases and trim and chamfer. Someone previously suggested, correctly, giving your bullets a "rattle" test in the muzzle. In my experience, many factory cast 30-30 bullets have small-in-diameter noses to ensure perfect feeding for Cowboy Action shooters. For target shooting, the nose of a bullet should be a snug fit on top of the lands. If the nose fits loosely, it starts down the bore cocked in one direction or another. You have a micrometer, so measure the noses of a couple of those bullets. .298" or less in diameter means they likely won't produce good 100m groups. Close to .300" means they should give good 100m groups. Don't worry so much about inside neck diameter. Just make sure it's .001" or so less than bullet driving band diameter. When you get the rifle shooting well, then experiment with dfferent inside neck diameters. Here's a group shot with my M94 30-30 with peep sights. This is with a similar bullet to yours and almost the same load of powder. It was with new WW cases. If my rifle can do this with iron sights, yours certainly can with a scope.  | |||

|

| one of us |

Clark, I hate to ask a question like this of an experienced shooter, but: Where do you place the gun on the front rest? The farther forward you rest the rifle, the more shock is imparted to the muzzle as the boolit travels down the barrel. Are you resting the gun just in front of the lever? Does the rear stock rest against your shoulder the same way every time? No offense intended by such basic questions. If you decide to try to accurize the rifle, it isn't difficult. Just remove the barrel bands and the mag retaining screw at the point where the mag tube joins the action, and the magazine and forepiece will slide out. If the pieces fit tightly, relieve the metal and wood to allow a clearance of a few thousandths. Tight-fitting parts impart the barrel vibration to the whole gun. This simple modification frequently cuts group sizes in half. One other thing to check is to make sure the tang-to-stock fit is tight and that there's no wiggle between the metal and the rear stock. I use "once fired" (which really means "who knows how many times it's been fired") 30-30 brass of mixed headstamps. I have a number of 30-30 lever guns spanning an age of over 100 years, and they all shoot to 4 moa or better with iron sights. So, I'm still convinced that there must be something other than the ammo causing your problem. | |||

|

| one of us |

Junior1942, I can buy some cases. The nose on the 311291 bullet is ~1/4" long. It varies in diameter from .3005 to .3025". grumble, The rifle is very light, the slug heavy, and the barrel is not floating. To deal with that, I put the rear of the fore stock in the steady rest. I try to pull the trigger with opposing force from my right thumb on top of the stock. I was using a bunny eared rear bag that I pinch to get on target. The rifle was not tight against my shoulder, but touching my jackets. OK, I took the tube and for stock off. The clearance seems small to nothing on both stock and tube, but not interfering at this time. The rear stock is tight. I was getting 1.2" groups from an M39 shooting 180 gr bullets at 2750 and 1.5" grops from a Mauser shooting 200 gr at 2630 fps the same day, so recoil is probably not the problem with the Model '94. Those heavy kicking guns have floating barrels and I was able to position the steady rest much closer to the muzzle. | |||

|

| one of us |

Well, it ain't the shooter, it ain't the scope mount, and it ain't the rifle. What's left are the reloading components. I'll drop out and let those who are smarter than me come up with good ideas. If you can touch bases with Jumptrap, possibly on Aimoo, he's a real expert on lever guns. He's a fun guy to talk to even if he can't help. | |||

|

| one of us |

"The 30 short Lyman M die, for 30-30s was back ordered, and I used the 30 long that did arrive. It is meant for .308 and longer." Clark. I use the long "M" die for 30-30, .308, and 30-06. You can set it up with the base touching the shell holder and just adjust the expander back and forth to suit the round you are loading. In fact, the 30-30 case is a bit longer than the .308. Your bullets seem to have the proper nose size. Try seating those bullets out so that they are slightly engraved by the lands when chambering. The cartridges should be short enough to still work through the magazine. I've been loading the RCBS #30-180-FN that way and that bullet is longer than #311291, and it feeds just fine. The bullet seems to be hard enough, and I prefer hard bullets for the hotter loads in rifles. Less chance of stripping out in the rifling. Paul B. | |||

|

| one of us |

I would try a few other powders. My Marlin 30/30 likes 748 and BLC-2. My Savage 340 likes 4198 and 3031. My 14" T/C doesn't seem to be as powder sensative. The 311291 shoots good 1-3" at 100 yds out of all 3 of them. Mark Are you crimping your cases after loading? Another caster reminded me that 4895 needs a tight neck and making sure the case neck is crimped will help. Bullets sized .309 or .310 will help also. Different lots/makes of cases woill make some difference but not a lot in 30/30 usually. Like Paul B. said load the to lightly engrave the rifling and you should see better results. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Help a newbie with Win94, 311291, 25 gr IMR4895

Help a newbie with Win94, 311291, 25 gr IMR4895

Visit our on-line store for AR Memorabilia