The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Custom mold makers

Custom mold makersGo  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

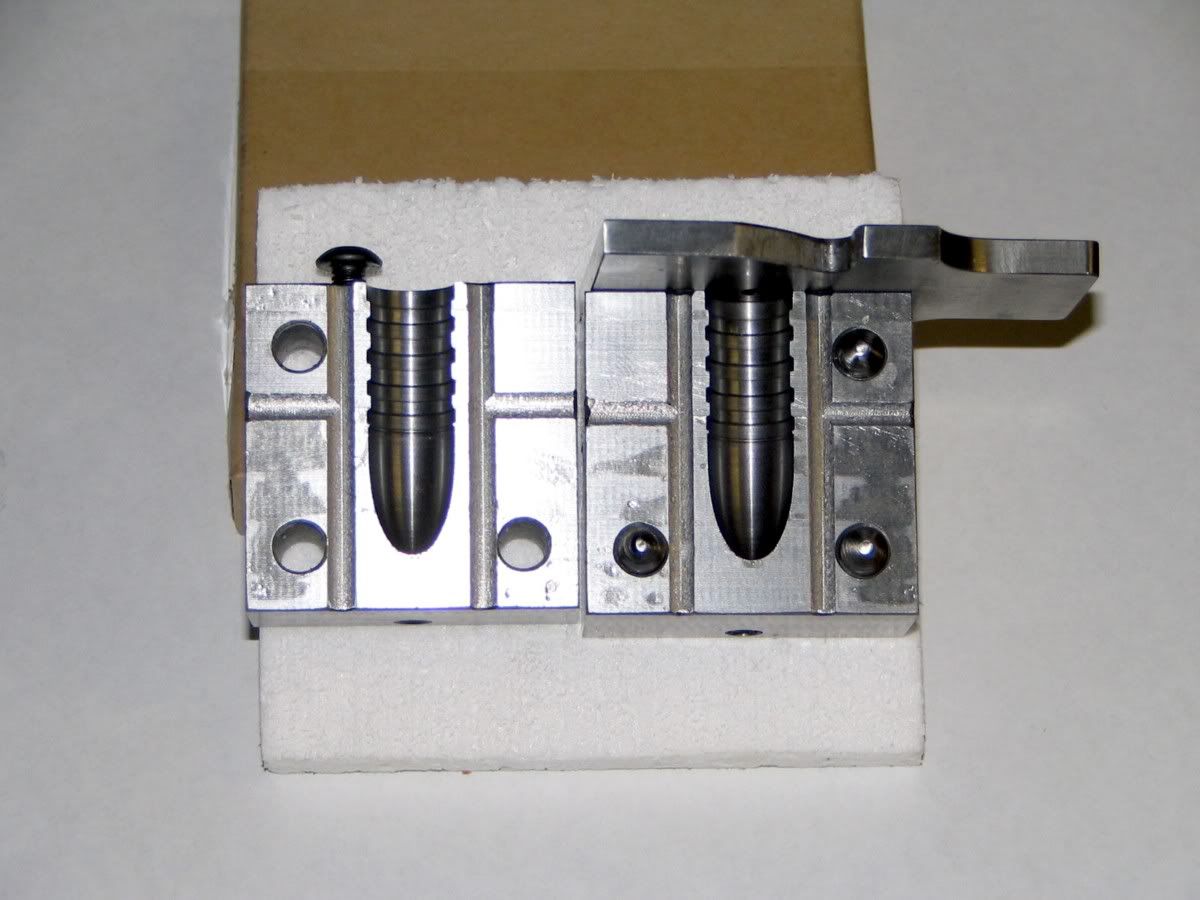

There is no doubt that bPCR is soon to be dominated by products from the custom mold makers. This mold from Victory is a 550gn 45cal bullet for long range competition. Note the special venting and the three alignment pins. When casting, the first thog you notice is that bullets drop from the mold without the usual bashing with a mallet. I weighed a sample of 20 from the first cast and was amazed to find they varied by only +/- 0.2gn. Now that is precision work; http://www.pauljonesmoulds.com/ http://www.victorymolds.com/  Hold still varmint; while I plugs yer! If'n I miss, our band of 45/70 brothers, will fill yer full of lead! | ||

|

| One of Us |

Beautiful mould, and a very nice profile. Should pour a gorgeous bullet, and one that is quite accurate. The only thing I would offer is that I have never had a problem with bullets releasing from a commercial mould, so long as I was ladle pouring using 1:20 alloy. Weights were very consistent as well (usually within three tenths or so). BPCR bullets from a bottom-pour pot weren't nearly as consistent, often varying by more than two grains. I don't understand that, but it is my experience... | |||

|

| One of Us |

That matches my experience exactly. Having said that, I suspect it depends on which method you "grew-up" with. I have friends who can cast bullets as consistent as mine using even the cheapo Lee bottom-pour pots, and they don't seem to do well with ladle-pouring. I, apparently like you, find ladle-pour is the ONLY method I can count on for weight spreads within +/- 0.3 grains over a whole casting run and my bottom-poured bullets vary all over the place. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| One of Us |

I get decent results with a bottom pour, but I have to be careful not to open the floodgate all the way. If I can keep it pouring slowly, I get the best boolits. There are some moulds I have that I don't have to worry about and can go full tilt, and a couple that only work with a ladle, but I will agree in principal that bottom pours can be a pain sometimes, especially with smaller and lighter boolits. ..And why the sea is boiling hot And whether pigs have wings. -Lewis Carroll | |||

|

| one of us |

BAW, When these molds were first talked about on BPCR I picked up something about the mold design that I cannot confirm but you might. The area around the cavity has an air gap. From what I read the entire cavity has the air gap for complete venting. EDG | |||

|

one of us |

This mold and it's design has been made by a machining genius in Steve Fotou. The entire mold face is slightly hollow ground about 0.0002", which is how the air escapes into the vent passages milled very close to the bullet cavity. For best results, do not put the ladle into the sprue hole just pour until the cavity is full and a small puddle of alloy is on top of the sprue plate. Would I buy another; you bet; an order for a competition bullet for my 32/40 Schutzen has already been placed. Hold still varmint; while I plugs yer! If'n I miss, our band of 45/70 brothers, will fill yer full of lead! | |||

|

| one of us |

BAW, Do you cast with a dipper or a bottom feeder? By the way it would be easy to vent an existing mould in the manner the Victory mould is vented using a vertical mill. I have a cheap Lee that would make a good test. Ed from the land of Big Foot Wallace. | |||

|

| one of us |

Just cast 100 (beautiful) 32/40 bullets with my newest Paul Jones mold. Worth every penny of the current price of $175. Paul (a one man operation) might not be making molds too much longer so if you ever considered ordering do it "sooner than later". Jon | |||

|

one of us |

Jon, What bullet did you purchase? I have a new gun being smithed now with a GM barrel ans I was thinking a custom bullet around 210-215gn. Hold still varmint; while I plugs yer! If'n I miss, our band of 45/70 brothers, will fill yer full of lead! | |||

|

One of Us |

NICE mould...... "Bitte, trinks du nicht das Wasser. Dahin haben die Kuhen gesheissen." | |||

|

| one of us |

My bullet (30:1 alloy) weighs 213.4g. It's a tapered spitzer of .321 dia. designed for breech seating. The groove dia. of the Douglas barrel I installed on a Clerke (highwall) action is a little smaller than usual (.31975") and required a custom mold. I know Paul makes a few "standards" (45/70, 40/65 Creedmoors) but he will make (within reason) what ever you want for the same price. The spitzer I just got is sort of his "standard" scheutzen profile...just a little smaller in dia. Let him know what the bullet is to be used for, provide accurate bore measurements or a good slug, and you should be able to get what ever you want for $175. Jon | |||

|

one of us |

This is the mould design that I had considering ordering from Victory moulds - a 220gn 322 mould  Hold still varmint; while I plugs yer! If'n I miss, our band of 45/70 brothers, will fill yer full of lead! | |||

|

| one of us |

My Paul Jones 32/40 bullet has one less lube groove, a little flatter (less curve) ogive, and is 1.170" in length. Would be glad to post a picture if someone could tell me how to do it. The AR FAQ's are no help and I can't find posting instructions elsewhere. | |||

|

| One of Us |

Bad Ass, et al, Steve is cutting me a 375gr .376" mould for the up and coming 38-90 resurrection. One BP cartridge for all the world's competitions. Rich | |||

|

one of us |

Is that a 40/90 straight tapered down? Are you going for a fast twist barrel 1:12"? Hold still varmint; while I plugs yer! If'n I miss, our band of 45/70 brothers, will fill yer full of lead! | |||

|

| One of Us |

Hey Dave, still waiting for my knife.....smoker The beauty of the Second Amendment is that it will not be needed until they try to take it. --Thomas Jefferson | |||

|

| one of us |

What kind of handles do Paul Jones moulds accept?? Melvin | |||

|

| One of Us |

the original 38-90-217 Express case is 2.925" long. The germans necked it down .009" and created the 9.3x74R. I am just necking it back up to its' original size. Yes, 12" twist Krieger barrel, .367 and .375" L&G. I would order from Steve now if you want any more moulds. When I spoke with him a week ago, he was going to sell the business. Rich | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia