The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  338 gas check problem

338 gas check problemGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

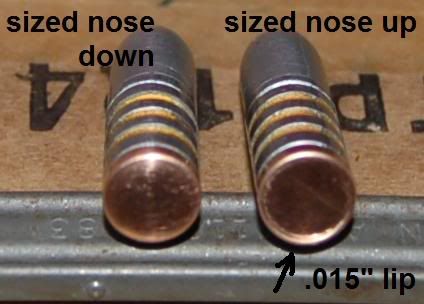

I cast heavy bullets for subsonic loads. I normally use a gas check as this improves accuracy especially with 458 and 510 caliber bullets. I do not have a 338 expander that bells the case mouth, so sometimes the side of the bullet is damaged when pushed into the base even when I use a reamer to eliminate the edge on the mouth. Using a gas check protects the bullet as it is seated and slightly improves accuracy. The 338 check is the thinnest I have seen, even thinner than the ones for .308 bullets. This leads to a lip being formed. I have tried this with Gator and Hornady gas checks. I made a wider seater that barely clears the sizer, but the lip still forms. My solution so far is to push the bullet into the sizer backwards, or bottom up. I machined a 60 degree hole into the seater to keep the bullet straight as is pushed through. This eliminates the lip but results in a slight bulge in the gas check. I have yet to shoot them. Any suggestions? Thanks.  Ranb ______________________________ In my opinion the best accessory to put on a rifle is a silencer. | ||

|

| One of Us |

i try to get that little dimple in my 358 wins. they shoot better that way. you could try making a short rod that is the same [.001 under] size as your sizer. i do that for my 223. | |||

|

| one of us |

I made a rod as tight as possible that would still fit. I even tried using a gas check upside down on the top of the factory rod that tightly seals to the die. The gas check on the bullet is so thin that it still makes a lip. The lip is never even. I think any uneven base on the bullet is going to reduce accuracy. Ranb ______________________________ In my opinion the best accessory to put on a rifle is a silencer. | |||

|

| one of us |

Went to the range this weekend, the 338 bullets that are sized nose down do work a bit better. Ranb ______________________________ In my opinion the best accessory to put on a rifle is a silencer. | |||

|

| One of Us |

Try the Lee universal expander for cast bullets. For many years I've used my home made "M" type expanders for cast bullets, but a few years ago I bought one of the Lee tools. It works great. You cannot discover new oceans unless you have the courage to lose sight of the shore | |||

|

| new member |

Ranb - You might not believe this. I cast for .30 cal and usually don't have any issues at all with gas checks.........however, I have one Lyman mold that the GC just will NOT seat properly on no matter what I do it either shaves lead or leaves a ring of lead from being seated. Check won't just snap on the base either. Don't have this issue with my other .30 cal bullets. I've looked at "magical" fixes, homemade GC tools (I may buy one of those yet....) but the easiest thing I've found so far I found while looking at the check and roaming around my workshop. I found an itty bitty ball peen hammer my wife has teased me about for years. Got to looking at the ball end...........it fit the .30 cal GC just about perfect. Took a GC, put it on a piece of flat steel, gave it a light whack with a rawhide mallet.......and it snapped right on and seated perfectly through the sizer die now. Just an idea for you man. Art | |||

|

| One of Us |

You might want to try annealing the gas checks before you put them on. May work----may not. Just put a few checks in an old tin can and heat them up on the kitchen stove or? (red hot [or close]) and let them cool off (or drop them into some water). | |||

|

| One of Us |

you may need a larger sizer to just seat the checks. or a combo of techniques. then run through the regular sizer to size and squeeze them on. i have to flare the sides on my 41 checks to fit them on the base. then push through backwards. or they don't fit the base right. i also have some others i hit with a rod to square them up before putting on the base. they are rounded on the edges a bit some of this stuff is a pita but it's what it takes to get things right. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia