The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  paper patched cast bullets

paper patched cast bulletsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

just wondering could some one enlighten me in relation to paper patched cast bullets, are there any advantages useing paper patches...i have been told useing paper patches will not foul ones barrel, is this true????? does this mean one can push ones cast proj to a higher velocity with out loosing accuracy to fouling Daniel | ||

|

| one of us |

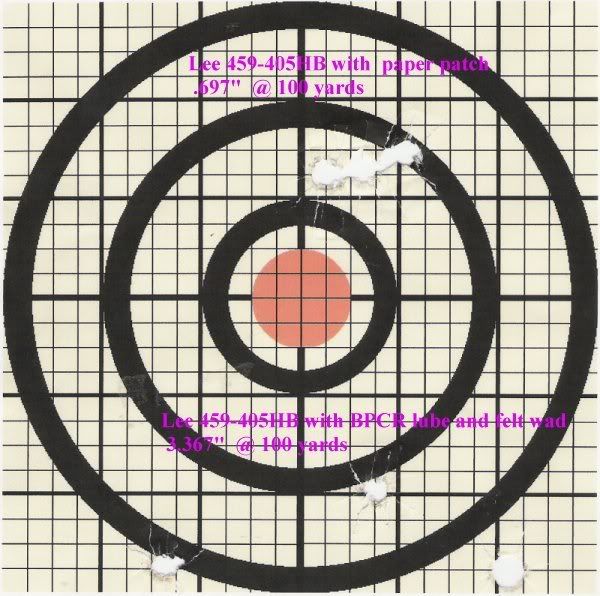

I am talking about paper patching for a Muzzleloader but I am sure that most of my comments will be the same for a CF. Question 1- yes the advantages are many. Since the fire never touches the lead, the bullet will leave the barrel in better condition. I also use a over powder wad to help even more. #2- yes your barrel will NOT foul with lead. Powder will still foul but not as bad. #3- yes you can push a bullet faster with a paper patch. I use pure soft lead and I go up to 1600 FPS NO problem. I have heard of guys going over 2000 with pure lead. I have paper patched hard lead but they didn't seem to shoot as well without cleaning. My ML's are capable of shooting under 1" groups at 100 yards with peep sights. Here is a target I shot that shows what the difference is with paper patch and no paper patch. My 45 has a 1-18 twist and is 32" long. Ron  | |||

|

| one of us |

RON thats real good accuracey its just that my RUGER 416 has a 1:10 twist, and i would like to get those cast proj out at about 2200 and am not sure weather casts with paperpatches would be better , or hard cast proj with GC Daniel | |||

|

One of Us |

M 98 I am on the same quest but just for fun I am taking a slightly different approach but after reading a few threads I am planning on testing out some paper patched 'swaged' bullets. I haven't figured out I will do it yet. so far I have been casting bullets then swaging them in the same mould to fill them out and impress the nose cavity. I started out casting the nose cavity but found it easier to swage it since I felt a need to swage the bullet anyway. My rifle has a rather generous throat which calls for a custom bullet. Regards 303Guy | |||

|

| one of us |

303 i spoke with veral smith and he says paper patched bullets are the way to go especially in the 416, he said no GC, no lube, no leading, and you can basically drive them as fast as you like....plus as has been mentioned you can use straight /pure lead which is a bonus also he said there a bit slower to assemble, but then how many will one use in a 416 in one session i mainly want to use the cast proj in my 416 to learn to shoot the big bore and keep costs down, as the cup and core proj get a bit pricy once you get to those cal Daniel | |||

|

One of Us |

Thanks. I am seeing another potential benifit to PP. Elimination of the need to size necks! The procedure I use at the moment (with paper cup seated bullets) is to dip the loaded cartridge into molten waxy-lube up to the bullet neck junction so that the waxy-lube can soak in. I then drip off the excess and wipe. I have tried the same with the 303 Brit but the waxy-lube does not grip the bullet. But with a paper patched bullet, the waxy-lube should hold it just fine. I am planning on making a split swage die (it will be held together in a taper collar) to speed up removal. The mould I have been using is a one-piece with nose pour and gascheck to seal the rear opening. I use the same mould as a swage die. Regards 303Guy | |||

|

| One of Us |

I would try it with and without lube. The NRA ran a 300 Win Mag to jacketed velocities with paper patched bullets. The best results were lubing the paper. I'd be careful with dead pure lead for paper patch and pushing it. Okay for normal long, but just like pure lead in cast bullets, you push them and you can run into some trouble with pressures. | |||

|

| one of us |

SM do you know if they used pure lead for those velocities , or was it a WW /mixture Daniel | |||

|

One of Us |

M 98, have you made any progress with paper patching? (I haven't - I have only recently tested my cast bullets. I was pleased with the results but need to do way more testing). Regards 303Guy | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia