The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  Making your own molds

Making your own moldsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

One of Us |

First off I was wondering who here makes there own molds? 2nd methods of do it, and what are your tolerances to be expected? I m picking up small things here and there, and am currently in a prosision machining corse at KVCC.me.edu in Fairfield Maine. So that a side, I would like to give a shot at making my own molds and see how they turn out. There is something to be said about things you make your self. You just cannot beat that feeling. Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | ||

|

One of Us |

Yup. It sure is rewarding making it yourself. My trick was to go for nose pour, smooth sided because they could me made easily on a lathe. They have advantages but mine have been slow to cast from. A split mold can be made on a lathe too but I haven't done it. But if you are going to make a mold you can talor it to suite your particular rifle throat. I would suggest a louverin design stepping down from base shank diameter to bore diameter at the nose. Another thing to consider is making a push through sizer die that works in your reloading press. That would make mold tolerances less of an issue. Yet another consideration is an adjustable mold. Easily do-able. That and a push through sizer will have you covered for 308 and 303 Brit - one mold and two push through sizers. Then - swaging dies that work in your loading press! There's a ton of fun things you can make! Check this out; Hornet bullet swaging dies that utilize spent 22LR cases for jackets. This is my third attempt. It's split to facilitate removal of the swaging.  Whatever you choose to do, have fun doing it! Regards 303Guy | |||

|

One of Us |

You know I was just thinking of a casting mold, but if I could make a lead swaging mold for my press! Swaged lead I here is better shooting then cast. So why not! But the only problem on my end would be all my work will be done by hand, bench grinder, drill press, hand grinder, small welder(cannot weld over 1/4 stock). I have access to a full machine shop, but the problem is with all the political corectness BS our country is mandating everywhere I cannot get away with making molds or dies. But I can get away in making a swaging press. Hey I making a tomato can swage press used to make cans for chary tomatoes! Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| Moderator |

Have you considered buying a blank mold from Lee, and just making the cherry to cut it with? for every hour in front of the computer you should have 3 hours outside | |||

|

One of Us |

Dose RCBS sell blanks? I do not do business with Lee. Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| one of us |

I have made a pile of them from scrap aircraft aluminum. One of these was a mistake. I made one cavity for the .45 and the other for the 45-70 revolver. Both shot so good I had to go back and make another double cavity for the 45-70. I make the cherries on my lathe but there is a lot of hand work to them.  | |||

|

One of Us |

Ok so I am so green, what do you mean by cherries? I was hoping someone would brake down the hole deal. I am in the beginning phases of learning to machining. I just cannot get enough info on the subject! I have 3 projects to complete in this class, and 2 of them are for my bench. One will be a 2 axes table to turn my lath into a milling machine. The other will be a hydralic swaging press. I am to start research on all these projects now. Anything extra I do at home will benefit my class and may earn extra credit. I am a hands on guy and relaxing is time in shop on my own projects. So thats why I would like to see if I can make my own molds. Thanks for all and any help on all subjects! Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| one of us |

The cherry is the cutting tool shown behind my boolits. The blocks are closed evenly on it with a vise that both jaws move to the center on. You can also lathe turn blocks but it is way harder to set up and measure, CNC works best. Special cutters are needed and the machine must track perfectly. I can't do that with a Smithy lathe/mill. | |||

|

| One of Us |

A "cherry" is a type of drill that cuts the mould cavity. It's shape and diameter is that of the bullet the mould is cut for. The Lyman Cast Bullet Handbooks have a chapter on how bullet moulds are made. | |||

|

| one of us |

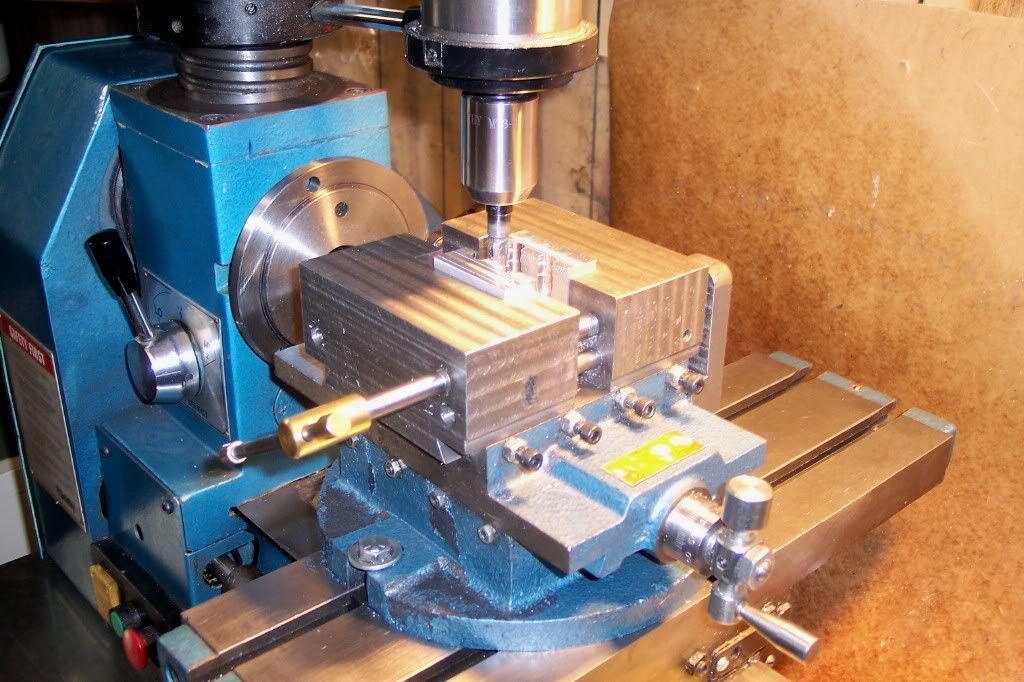

Here is the vise I made to fit my mill table. The jaws move to center when the handle is turned. The cherry is in the mill head. Blocks are clamped in tight from the other side. I made this from cast iron risers I bought from a foundry. Lots of grinding and cutting, took two weeks to make the pieces.  | |||

|

One of Us |

Nice! bfshooter! Looks like it will be a little while until I can get my hands on or make my own 2 axes table for my press. I cannot afford to buy the real deal. What kind of bits to you use when making your molds? If your shooting for a paper patch or smooth wall bullet do you just use normal bits? I was reading up on swaging and you make swaging dies for lead bullets. Has anyone use and attempted to make those? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| one of us |

I cut the bits (cherries) from 1/2" drill rod. I cut the flutes with an end mill with the cherry mounted in a Vertex. You just make the end of the rod into a boolit first, then make the cutting flutes. I have to file the edges at the nose. Sharpen with a stone, harden and temper it. My biggest problem is figuring the diameter of a cherry to get the mold to cast the size I want. It has to be larger and each caliber boolit seems to need a different amount. My cherries are not shiny and pretty, I use a torch to harden them but they cut OK. You can buy a custom cherry but the last price I seen was $275. Kind of silly when you can buy all kinds of end mills and cutting tools for a few bucks each. Later I will take some more pictures. | |||

|

| Moderator |

James, Chapter 23, in Book 2 of James Howes "Modern Gunsmith" is about making bullet molds and if you can get a copy from your local library it will answer a lot of your questions. There are also PDF versions online if you can locate on of those, though I'm not sure of they are legit in regards to copyright (though they might be as the book was written almost 70 years ago). for every hour in front of the computer you should have 3 hours outside | |||

|

One of Us |

BF, good info there. By chance will I need a double or singel axes table when cutting these? Did you happen to take photos of the method in making your cherries? Thanks for the info very helpful. If I could do that it would be rather a empowering feeling to do such project. Thanks Mark, Thanks for the info. I will have to check it out. See if I can get my hands on a copy of this book. Thanks Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

One of Us |

I just happen to have a copy of that book!  Regards 303Guy | |||

|

| one of us |

I remove the top table of my milling table because the vice slides in it's place and I use the gibs to adjust out all play. That was easier then making a separate base. I lock the bottom up tight and just use the crossfeed to center everything, then I lock it up too. I looked for a picture for the cherries but don't have it. Next time I set up to make one I will take pictures. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia