The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  wad between powder and bullet

wad between powder and bulletGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I want to shoot 40:1 plain base 480 grainers for hunting with SMOKELESS in my Shilo 45-70 @ 1100-1400 fps. I need a good and safe medium between the bullet base to protect it from the powder charge. I need something that I can repeat with consistency and that will have no danger of ringing my chamber. Some suggested packing foam from what they call pick and pluck like you find in pelican cases, too bad it is hard to get and prohibitive expensive. I like to hear about truly well tried solutions. Thank you for your time. Shrike | ||

|

| One of Us |

"Walters Wads" are commercial vegetable fiber wads and come in a .030 and .060 thicknesses and in a variety of calibers. Midway sells them, as do other outlets. If you want to make your own wads, use the cardboard from a tablet (coat with mica) or cut some from the plastic coffed can lids. NRA Patron Life Member | |||

|

| One of Us |

Do you really think you need a wad at that velocity?? What do you guy's think?? I do not use one at 1600 fps, and I do not use a GC either. No problems yet. I cast from straight WW. I do not use a hot or fast powder in mine. I prefer RL7. I think the slower powder's are better in the 45-70. I like to fill the case up as much as possible. Just my opinion. Tom. WEST BY GOD VIRGINIA | |||

|

| one of us |

[QUOTE]Originally posted by HEAD0001: Do you really think you need a wad at that velocity?? Well, I always read that the base of those soft bullets need to be protected against deformation by the burning powder. Wheel weights are a lot harder then 40:1, which is very soft. BHN of 40:1 is around 6. Wheelweights are around 14.5. Soooo.there is a considerable difference in hardness. | |||

|

| One of Us |

I definitely agree with you that the alloy is softer. I am by no means an expert, I am inquiring as well as you are. I have been shooting my own cast bullets for a long time, and I just have not been able to tell any difference when I shot with wads. Maybe I was just lucky. I have casted and shot with different alloys over the years and I really have not noticed any major differences as long as I keep my velocity under 1600 fps. I cast for 4 45-70's, and several 44 magnum's, along with a 358 Winchester. Maybe I am just lazy, but I spent a lot of time and money fooling around with different alloys and wads and such, but I could never tell much difference. Tom. WEST BY GOD VIRGINIA | |||

|

| one of us |

I use dacron in a wad to hold powder against the primer in my 45-70 loads. I buy it in the form of batting from Walmart. it's easy to get the wads to be very close in weight using batting. I buy the one half inch thick size for 45-70 and cut a long strip one half inch wide. Then, I cut pieces off, again one half inch long from the strip. I used a dowel 3/8" wide that I have carefully smoothed the ends to lightly press the wad against the powder. The bullet I use is the Lyman #457122 Gould 330 gr. hollow point which is a plain base bullet. My powder of choice is SR-4759, in a 16.0 gr. charge which gives me about 1600 FPS with very good accuracy in my Ruger #1. Paul B. | |||

|

| One of Us |

I use Dacron also. But you shouldn't call it a wad, it should be called a filler. It should not be pressed down again the powder. It should occupy the space between the top of the powder charge and the base of the bullet. This way you don't have to worry about any of the horror stories happening that you hear about using wads and fillers. Here's what could happen if you tamp it down on top the powder. There is a space then between the wad/filler and as the powder burns and pressures up, so does it compress the air space just spoken about and this can sometimes ring a chamber. I know lots of people have shot it this way and gotten away with it, but it can happen. Wads (like in cardboard type) over top the powder with a space left between it and the bullet base almost guarantees a disaster of some sort. | |||

|

| one of us |

You could paper patch the bullets. That would be your best bet I think. I am paper patching with lead as soft or softer than yours in my Muzzleloader. I am paper patching a Lee 459-405-HB, and shooting them in my .458 Green Mountain 1-18 twist. I get great groups and paper patching is repeatable and easy. Ron | |||

|

| One of Us |

Hey, lead is lead...how could one be softer then the other unless it's not pure and has hardening alloys in it. JUST KIDDING Really I'd like to know how you get your paper patched bullets down the bore. Especially after it's been fouled from shooting previous shots. Doesn't sound like a bad idea and that you have success with it. Are the paper patched bullets just barely fitting then obturating up to bore and groove size upon firing? | |||

|

| One of Us |

I've shot hundreds of straight WW cast bullets (Lyman #429421 & 358477) through my .44 mag and .357 mags with no wads and no problems. They're only going 1300-1400 fps, and inspection of the bases of recovered bullets show no ill effects from the burning powder. NRA Endowment Life Member Life Member Wild Sheep Foundation | |||

|

| One of Us |

Although the powder gases have enough temperature to melt bullet alloy, it just doesn't have enough time to act on the bullet. You know, the old finger through a candle flame fast then slow thing. Very hard to find a melted base. Now gas cutting, that might be diagnosed wrongly as melting, it factual. | |||

|

| one of us |

Probably my best bet would be to load up some with and some identical loads without wads. If there is a difference then I will know what to do next time. Someone in red deer suggested I go to a denturist and get their sheets of dental wax 1/8inch thick. Then place the sheet on top of a loaded case, then thumb a disc of wax down the case. Put over it a newsprint disc to prevent the wax from sticking to the bullet base and seat the works down with the bullet. This works only in straight wall cylindrical cases I guess. The danger in a tapered case might be that the disc could work itself downwards if the case would be exposed to drop or vibrations in a vehicle, creating an airspce betweeen it and the bullet and ring a chamber. Another suggestion given from Alaska was to use "popcorn styrofoam" packing material, so often found in appliance and computer boxes as packing material. Put the popcorn styrofoam on top of the powder and fill always up to the top of the case, then seat the bullet on top, this way it will be consistent from load to load with no danger of airspaces. Well, it seems there are many ways to achieve the objective. We got to try different options. Thank you all for your input guys! Shrike | |||

|

| one of us |

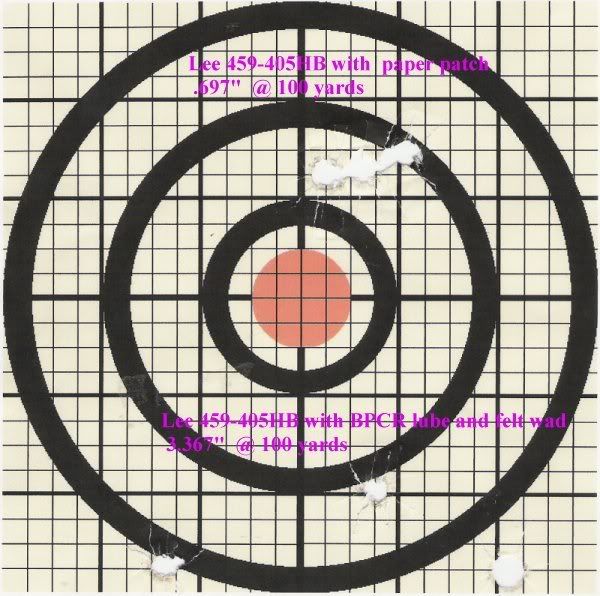

On this picture I am posting is two groups one is with paper one is without. My 45 is a .458, so I size my lee 459-405-HB's to .451 then I paper patch them. After I wrap them I size them again to .451 I can easly shoot 3 shots between cleaning and most of the time I can shoot at least 5 to 10 between cleanings. I also paper patch 500 S&W bullets for my 50 cal muzzleloader. That bullet is a Lee and it shoots amazing. I can shoot 4" groups at 200 yards with open sights. Like I said this picture says it all. Ron  | |||

|

| One of Us |

That's quite a difference. So basically the paper patched bullet is very easily to get down the barrel since you size it well below groove size. Interesting. | |||

|

| one of us |

It still is tight enough to stay on the charge, but it is easy to get down the barrel. Ron | |||

|

| One of Us |

Ron; I will give this a try, but time to do it is the holdup right now. | |||

|

| One of Us |

I would suggest you get a brick of florist foam from the local Wally World, slice it in 1/8" sheets with a mitre saw. Put the foam over the mouth of the case, push down with your thumb to cut a "wafer" of foam, and push the plug down over the powder with dowel or similar. I did this with a 45-70 and AA 5744. It worked very well, the foam burns well before the bullet ever exits the barrel... | |||

|

| One of Us |

Please do not consider this a stupid question, or a rude response. But what happens to the foam?? There has to be residue left over. Especially on the brass?? It seems to me like it would also leave residue in the barrel?? I did try Puf-Lon once. The results were very disappointing. Tom. WEST BY GOD VIRGINIA | |||

|

| One of Us |

Head001, the krinkle foam is probably used by 90% of the schuetzen shooters. The weight is about 1/20th of a grain, so the ejecta mass has no effect. It flashes into dust at the touch of a match, and adds no fouling that I have ever heard of. I shot many schuetzen matches where I fired fifty or more shots without cleaning the rifle, and the last group was as good, or better than the first. Rich DRSS Knowledge not shared is knowledge lost... | |||

|

| One of Us |

In Charlie Dell's book "Modern Schuetzen Rifle", he discusses wads and ringing chambers. Very interesting reading. If I remember correctly, he found that a wad pushed down against the powder would eventually ring the chamber. But remember he was generally talking about old steel which is softer than modern day steel. But even modern steel would eventually get there. If the wad, preferrably florist foam, was seated .2" ahead of the powder, the problem went away. It appears that the ringing had something to do with the shape of the powder charge. That is, the ringing took place even when the rifle was pointed straight up and fired without a wad, thereby, creating the same 90 degree angle to the leading edge of the powder as a wad would have created. When the florist foam was seated .2" ahead of the powder charge and fired normally, the leading edge of the powder charge trailed down and was not at 90 degrees and no ringing took place. The loads I use for schuetzen type shooting generally run 1100-1400fps. I never use a wad of any kind with no bullet problems. I most generally use 30-1 but sometimes 40-1 or 25-1 depending on what the rifle likes. FWIW Phil | |||

|

| One of Us |

Phil, I "invented" the 32 Miller Short back in '91 by convincing Dean Miller to shorten his 32 Miller by 1/4". The standard load is a 215-235gr semi-spitzer ahead of 9.5-11gr of AA#9. I probably shot 10,000 rounds thru two of them with the krinkle foam wads, as well as nearly every top Schuetzen competitor the last sixteen years. It makes news when somebody wins a big match shooting something else. Rich | |||

|

| One of Us |

Rich When you say "krinkle foam wads", is that the green florist foam or something else entirely? Phil | |||

|

| One of Us |

A wad no matter what the material should never be pushed down against/atop the powder leaving an airspace between it and the base of the bullet. I've heard ringing chambers from doing what I mentioned above. Something to do with the wad compressing the air between itself and the base of the bullet rings the chamber. In less severe cases it ripples the cartridge case. I still think Dacron is the way to go. It expands an fills that airspace very well and is much easier to use then the foam. | |||

|

| One of Us |

If you are shooting a 40:1 I would use a gas check bullet,or with a plain base bullet a .060 wad pressed into the case mouth, letting the bullet push the wad the rest of the way into the case. For powders the sky is the limit, everyone has a favorite. I use AA-5744 in a 45-70. I have also heard of people using backer rod cut to length so the bullets base compresses it against the powder, leaving no air space between the powder and bullet. Yes the wad will protect the base of your bullet allowing you to shoot at 1100-1400 fps with 40:1 alloy with no leading. | |||

|

| One of Us |

You can buy it at Home Depot...at least you can in Oregon. There are two kinds of florist foam commonly found, both green. One is dark green, very small pores and is commonly called "Oasis" foam. It is the one you want. The other is much larger "pored", rather mealy, actually, and is a light green. You do NOT want it. It comes in "blocks" (bricks?) To use it, saw off a sheet the thicknes you want your wads to be. Pour powder into cases. Then press a sheet of the foam over the mouth of the case, using the case as a "cookie-cutter" to cut its own wad. Do not shove the wad on down into the case. Just sit the bullet in place and seat it. It will push the foam to where you need it to be. It has all kinds of advantages. It does not melt in the hot sun; cartridges can be carried about in virtually any position; it does not get you or anything else dirty when loading; it will not "kill" either powder or primers if it gets in direct contact with them; it is cheap like borscht; it does not dirty bores when the cartridges are fired; you can leave it laying around on top the loading bench with no problems; etc.; etc. | |||

|

One of Us |

What happens if the wad (cardboard) is stuck to the bullet base with lube, either before seating or during seating? I have recovered bullets with the wad still stuck on but this was firing into a bullet trap close up. Will that wad come off mid-range? If so, would it affect accuracy? (It would surely come off at varying distances). Regards 303Guy | |||

|

| One of Us |

I do not use any "wads" anymore. I use a dacron filler pretty much the same as Paul H and Starmetal advise. It is the surest, safest and produces the best results accuracy wise. Larry Gibson | |||

|

| One of Us |

Another medium some use is cutting wads from the foam meat container trays. I've used the yellow ones from family package sized chicken wings or legs. They are fairly thick, nearly 1/4 inch. The way to do so is take your case with powder charge, no bullet yet, then merely use it to cut a wad out of the container. This insures that it's always up against the bullet. If you want thicker just cut another over the one you previously done. Bullshop from castboolits talked about this a lot. Only thing I don't like is having to make sure you wash the tray thoroughly so as they don't smell and more importantly don't have salmonella on them. Don't let this turn you off, as they are quite acceptable afterwards. Joe | |||

|

One of Us |

And this doesn't melt and foul the bore!? Are your meat trays the same as ours? Polystyrene? This seems like a great idea! Regards 303Guy | |||

|

| One of Us |

No it doesn't. Ironically Dacron doesn't melt and kapok fiber doesn't burn. For one thing there is just too short of a time factor for the heat to apply itself. Look at plastic sabots and plastic shotshells and shotshell wads, they don't melt. The longest exposure to the heat is the interior of plastic shotshells. They do get rough from the heat. Even paper shotshells don't catch fire with blackpowder. Joe | |||

|

| One of Us |

Here in NZ, sheep wool wads - about grape size - are on sale (.303guy, try the Cast Bullet Kid - CBK on Trademe - and are quite effective). For a few years, I used semolina mixed with graphite powder - 1 cup semolina to 2 teaspoons graphite powder as a filler. My load in a .303 was lyman 314299 gas checked, 18.6gr of AR2207 - also sold as H4198 - and topped off with the filler. No problems and groups shrank from 10 shot 4" at 100yds to 2.5" . As I got the same results with the wool wads, I threw the filler away and now just push the wool wad lightly down onto the powder. Arte et Marte | |||

|

| One of Us |

Then you have been lucky. Never never never push anything down on top the powder and leave an air space between it and the bullet base. You can ring your chamber or worse. Like I said you've been lucky. Other's here will more then likely back what I just said. Joe | |||

|

One of Us |

Thanks starmetal and KimW9. I had often looked at those packing trays and thought how great that would be if only I could be sure the edges wouldn't melt and foul the bore. Now that I know ..... Mmmmmm .... ! Actually, I was thinking of impregnating the stuff with lube so as to lube the bore on firing! Does using packing tray wads eliminate the need for gas checks? starmetal, this ringing of the chamber in the neck area, is that likely to occur when a slow igniting and/or burning powder is used at low pressure? Regards 303Guy | |||

|

| One of Us |

| |||

|

One of Us |

Aahhh .... well .... ummmm ....! OK, it is not a need, just a desire based on a notion that lubing the bore might be beneficial from a bore cleanliness point of view. And a desire to experiment! P.S. I have been wrong before, (too often), so I will be taking heed of warnings! Regards 303Guy | |||

|

| One of Us |

I was just concerned of lube and powder mixing. If you can prevent, then give it a try. Let us know the results. What effect will hot summer days have on your method? Will the lube get soft enough to seep then? Joe | |||

|

One of Us |

Good question! We don't get too hot here but warm weather and direct sun? I will check it out. Thanks for the warning. Regards 303Guy | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Cast Bullets

Cast Bullets  wad between powder and bullet

wad between powder and bullet

Visit our on-line store for AR Memorabilia