The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Modern Military Rifles

Modern Military Rifles  What the Hell!! AR-15 jamming Part 2

What the Hell!! AR-15 jamming Part 2Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Hello Fellas, Many of you replied to my previous post regarding my AR-15 jamming with 69gr but not 55gr ammo. Many of you felt that I may have a magazine problem, so I replaced the old followers with the new anti-tip ones and headed to the range today. Two mags shot OK and then the same problem started all over again. Maybe I jumped the gun thinking it was the 69gr bullets, so this time I took more care to see what is going on. Here it goes, and I will add that I replaced my carry-handle style upper reciever with a flat-top upper reciever. Maybe I screwed something up? 1) The most obvious thing I see that dosen't look right is that the bullets are getting stuck in between the teeth (whatever you call them!) of the chamber...you know, the teeth that match-up with the teeth on the bolt-head. Some of those bullets really dug in between them. So in other words, the round is getting stuck half way out of the magazine, between the bolt head and chamber/teeth to chamber. If I pull back again on the charging handle and let it go, the round will chamber and fire. 2) If you were to lock the bolt open with a loaded magazine in place and look into the ejection port, it almost looks like the rounds are too "low" to enter the chamber, since they are lined up with the so called teeth of the chamber. It's driving me crazy, so I hope that you guy's can help me out here. BTW the lower is from Bushmaster and the new flat upper was purchased from Bravo Company. As I am typing this, I am thinking that it must be something with this change, since I never remember it jamming in the past. What the Hell is going on!! Thanks Frank | ||

|

| One of Us |

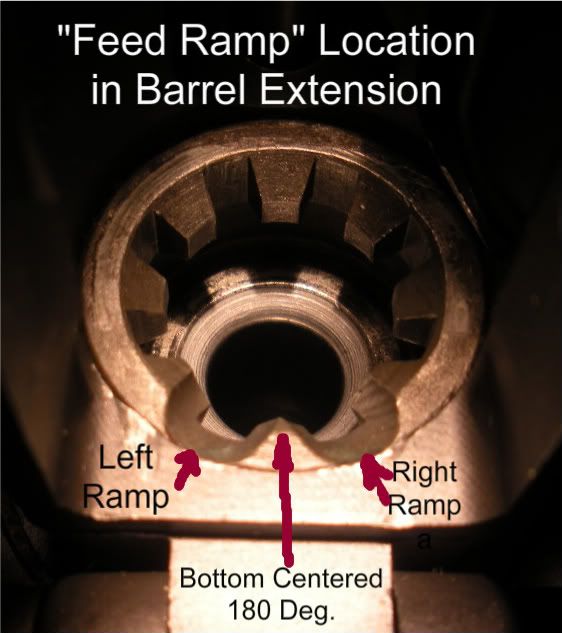

I would guess that the barrel wasn't properly indexed/torqued. Did you torque the barrel to the upper yourself and did you you use the proper torque specs? The two (right and left) "feed ramps on the barrel extension must be in the proper position. I'll post some pictures to show you why this important. | |||

|

| One of Us |

DaMan, I should have known that you would come through for me! I didn't torque anything...I just tightened it up until it stopped and that was that! I did put that metal protrusion on the barrel into the slot on the reciever though... I can't wait to see your pictures to see where I F-ed up! Do I need a torque wrench/device? I have no business doing this kind of work, but it is fun! I did, however, install my Rock River NM Trigger sucessfully! I have to run out now, but I'll check ASAP. Thanks DaMan | |||

|

| One of Us |

Not good, Frank! It sounds like you are one hole off from the proper position. It's BEST to use a torque wrench..... but it is possible to mount the barrel without a torque wrench. But remember, the best accuracy is achieved at the lowest recommended torque at which you can get the barrel to line up properly.  The odd number rounds (1st, 3rd, 5th etc.) in your mag are fed up the left side ramp and even number rounds go up the right ramp! This will make sense when you look at the loading pattern in the mag. Odd number rounds up left ramp....  Even number rounds up right ramp.....  Make sense? | |||

|

| One of Us |

The way I do it is to tighten the barrel nut with the proper tool, which is a $30 wrench made just for this purpose. I tighten the nut until it gets very tight, but I don't go apeshit on it. Once it's tight, I look to see if the next hole is too far away or if maybe I can reach it. If it takes too much effort to get to the next hole, I back off to the hole I can reach and then the gastube goes in. When I say hole, I'm talking about the nut onto which the free-float handguard screws. For split handguards, there is a toothed nut-- looks like a sprocket on a bicycle wheel. The torque spec is 35 pounds-feet when using the proper tool. But I look at it this way: If I try to reach 35 pounds-feet, I might strip that thread and be out what the upper cost me. So I go as far as the holes/teeth will allow and stop there... | |||

|

| One of Us |

What an idiot I am!! Damm, I didn't even notice the two ramps. Well, guess I have a project for today. The more I learn about these guns, the more I can appreciate how beautifully designed the AR rifle is. DaMan thanks for your effort with pics Brewer I will torque to your specs and I'll let you know how it works. Frank | |||

|

| One of Us |

Be careful. Make certain the little pin on the barrel is setting deeply into the little slot on the upper. Wipe a small dob of grease over the threads on the upper. Run the nut on and off with your fingers to spread the grease. Lock the upper into a vise with your action block. I don't use a block because my vise is of such a width that I can use it without the block. The jaw fits between the two pivot pins, holding the upper nice and tight. The jaws are padded with masonite. But that's what I have. You need to deal with what you have. So, run the nut on with your fingers. Tighten with the wrench. What I do is then tap the wrench with a hammer to align the best hole in the nut with the hole in the upper and leave it there... | |||

|

| One of Us |

If you aligned the locating pin on the barrel with the notch on the upper you should have the feed ramps in the position in DaMan's picture. The later uppers have a set of dished out ramps in the upper itself that extend those ramps. I've got uppers made both ways and if there's a gap it might cause a snag. You might make sure that if those are present they make a smooth transition into the feed ramps in the barrel extension (the part with the teeth). I've seen torque values all over the place in regards to tightening the barrel nut. The best fix I've found is use a touch of grease on the upper threads and tighten the nut firmly but be mindful that you are working with an aluminum part and you have to get the nut to line up in a way that still allows the gas tube to pass thru it. This barrel worked OK with the previous upper, right? A picture being worth a thousand words and not being able to produce pix like Da did, I snagged this photo off the web.  | |||

|

| One of Us |

Fellas I have the gun apart as we speak, and I'll let you know how it goes. One other thing I noticed when I cleaned it from shooting yesterday is that the piece on the carrier that meets the gas tube is pretty loose. I just de-greased and lock-tited it and tightened the hell out of it. Could this also be a contributing factor? Guys the pic's are a big help...thabnks for your time! | |||

|

| One of Us |

I think what you are talking about being "loose" is known as the gas key and just using LockTite is not a solution. That part needs to be torqued and machine screws holding it in place "staked" by using punch and literally deforming the surrounding metal in order to prevent the screws from coming loose or "backing off..." Looking down on the screw heads, place one stake at say, 12 o'clock and other at 6 o'clock on both screw heads. It is important that it remains in place for the gass emitting from the tube is what drives the bolt rearward and cycles the action. As you can imagine, temperatures are high and the adhesive/locktite, etc. will not hold over time and this part being loose will cause the rifle to malfunction. | |||

|

| One of Us |

"Leopardtrack", I think you should get another rifle as this "AR" you have is causing you an UNBELIEVABLE multitude of problems! | |||

|

| One of Us |

The guys on AR15.com have attributed loose gas keys to causing everything from hangnails to impotence! Martin's right, staking is the only method that has been shown to fix that problem and a loose key will apparently cause bizarre malfunctions. But I'd always vote for buying another AR too. | |||

|

| One of Us |

Come on now, you are supposed to be giving me encouragement...even though you are right! I will try and shoot it tomorrow. If it's still F-up I am done with it. ! | |||

|

| one of us |

A loose gas key will usually cause malfunctioning. As others have stated it must be staked. It is one of the things you should check everytime you clean the rifle. DOUBLE RIFLE SHOOTERS SOCIETY | |||

|

| one of us |

Damn, man, did you install the barrel extension yourself? Otherwise, there should be no way for the feed ramps to get out of alignment, even if you leave the barrel nut kind of loose. BTW, screwing with the barrel extension affects your headspace. | |||

|

| One of Us |

Coole, I didn't mess with the barrel extension, I used the origional Bushmaster barrel, but I changed the upper reciever from carry handle to flat top. The ramps are lined-up properly, so maybe the problem is the loose gas key? I will hopefully shoot it tomorrow. Could a loose gas key cause this mess to happen??

| |||

|

| One of Us |

make sure that there are no burres on the gas tube or gas key from when they slammed in to each other if there are just remove before firing. also the torque is from 35-55 as long as the gas tube lines up, if its not perfect use a screwdriver with the gas tube in place and bend it slightly. | |||

|

| One of Us |

yes it can because if the gas key and gas tube are not lined up the bolt stops going forward but the round is half stripped so when you pull the charging handle back and let go it has the speed to force the gas key and tube to line up and chamber the round. | |||

|

| One of Us |

Leopardtrack, did you figure out which upper you bought from BravoCompanyUSA? They make both a flat top upper with no feed ramp grooves in the upper receiver (the upper you SHOULD have ordered for the Bushmaster bbl. you have)...... and they also make a flat top with the M4 ramp grooves machined in the upper. If you have the latter, you're going to run into the situation that Rick R described above. | |||

|

| One of Us |

OK Fellas, I'm back!! I am so pumped...I just put 10 magazines (250 rounds) through the gun with NO malfunctions. Damm, what a relief...now I can stop bugging you guys. Thanks to all of you, despite myself, I fixed the problem. Here's what I did last night: 1) Tightened the hell out of the loose gas key, using red locktite, and I also put a small dimple on the screw/gas key with a center punch. 2) When tightening the barrel this time, I tightened it up as hard as I could until it stopped turning. The holes weren't lined up, so I backed off on it a little bit until the gas tube fit. 3) Finally (I know some of you will cringe when you read this!) I used my DREMEL with a small buffing wheel and polishing compound and I buffed my damm feed ramps to a mirrors finish!! Really, I put the dremel on the lowest setting and was careful not to F-around too much. So despite myself I got it working perfectly and again thanks so much! Take Care Frank PS DaMan...the upper from Bravo does not have the grooves on it. Thanks my man! | |||

|

| One of Us |

Woo Hoo! By Blur and performed by Sponge Bob | |||

|

| One of Us |

Glad to hear you successfully sorted it out. I still think you need another AR15, they are happier in herds | |||

|

| One of Us |

I have been thinking about it for a while now. I think that my next will be a 24" varmiter type with a nice 6-18 power scope. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Modern Military Rifles

Modern Military Rifles  What the Hell!! AR-15 jamming Part 2

What the Hell!! AR-15 jamming Part 2

Visit our on-line store for AR Memorabilia