The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  Bowhunting

Bowhunting  The Dauntless custom broadheads are here!!!!

The Dauntless custom broadheads are here!!!!Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

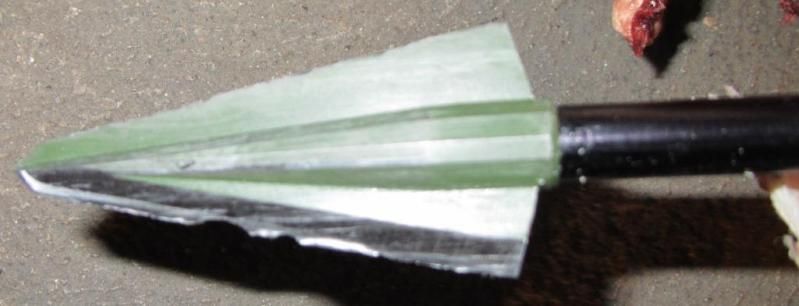

Vantage Point Archery made me some custom single-bevel heads. They have a unique "internal ferrule" design that calculates to be 8-10 times stronger than a normal ferrule. They should never break or bend at the connection to the broadhead. Ashby reported that he had a 16% failure rate there even with the best heads. This design should fix that. The downside is that only .3125 diameter shafts will fit - but any arrow that can be footed up to that diameter will work. So far it looks like the Easton Axis series, Easton FMJ DG250, GoldTip Kinetic DG200, and the Victory VAP 250 will work out to fit. The arrow length will need to be 1/2" longer to keep the back of the broadhead in the same spot. Since the arrow sticks up into the broadhead, the fulcrum is shorter and the tip is less likely to bend. The full-length rib from the ferrule forward does not hurt bend resistance at all, either. Another innovation (VPA's, not mine) is the offset blades. This lets the cutting edge be one single unbroken line all the way around the tip. This makes it easy to sharpen the tip, and makes it stronger, too. The bevel is 30 degrees to give good edge support. The heads weigh 273 grains, the custom Stainless Steel insert weighs 111 grains. A typical 2.5" external footer will add 20-25 grains to that. The heads are 2.45" long and 1.125" wide. The max ferrule diameter is .375", just like the traditional Grizzly Grande, and the ABS Ashby broadheads. Target hardness was R55. I need to test that.     Here's a poor picture of the tanto tip. I wish I could really show it to you - it looks like a real bone-biter! You can clearly see the offset blades in this view, and how pointy the tip is. The tip is well supported.  I'm going to take one out and break it on the angle iron tomorrow. Right now I'm just admiring them. The pics here are of the uncoated prototype. It shows the lines better than the non-stick coating. (The normal VPA coating.) If you want to buy some, talk to RAY@VPArchery.com, not me! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | ||

|

| one of us |

. | |||

|

| one of us |

.072" Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

I want! I want! I have some serious testing to do on serious animals. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| one of us |

Fritz, PM me. Rainer Josch has already expressed interest in using these for a May water buff hunt in Australia. I got 45 of these, and have ordered 24 practice tips, so we might be able to work something out. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

See: Cape Buff Arrow Tech Discussion for the testing history. Went to the range yesterday. It was very windy - about 20 MPH. The heads seemed to fly well in that wind, but I need a windless day. The arrows were an Axis ST 300, and GoldTip BG200KPs at 29". They BG200s weigh 769 gr complete, the Axis about 25 grains lighter. All destructive tests were with the Axis, as the BG200KPs are expensive! Edge view of a production, coated Dauntless.  Here's a plan view. Sorry about the quality of the pic.  I first shot at the 5/8" OSB. Four shots, four blow-throughs. They seemed to make smaller holes than the other single-bevels I've shot at the OSB. It may be the coating? Not a mark on edge or coating afterwards.  I then tried some 5/8 shelf board (coated particle board) from Home Depot. Same result with bigger holes.   I then couldn't stand it any more and pulled out the angle iron. The results were pretty spectacular, with pieces of arrow seeming to fly everywhere. Here's the target with the footer showing on the right and the end of a 12" piece of arrow on the left. The angle-iron had been in the middle.  Here's the pieces.  Here's a pic of the angle iron. Note that the tip dug in to the iron and scooped out a small piece as it rotated. It then appears to have recoiled a bit (bounced) then cut a groove down the iron. At the edge you can see a curl where the back of the edge of the head cut the iron again. The curl is blue from the heat generated.  Here's a pic of the head and footer. The arrow broke into three pieces. The damage to the footer shows that it hit the edge of the angle iron almost flat. The footer/insert section unscrewed from the Dauntless easily. The shroud of the Dauntless was undamaged. The back corner of the blade was slightly curled where it shaved the iron. The tip was bent about .25" back. The tip itself was completely undamaged, not smeared at all. I wish I could show it to you better, but I'm not a good enough photographer. (The coating missing from the bevel was from me sharpening the head by hand. This is the head that went through the OSB 4 times and the shelf board twice, with no apparent damage to the coating. I wonder what that stuff is?) I can't begin to tell you how pleased I am with these results. The ability of the tip to cut into the iron while maintaining the tip shape tells me that the tradeoff between toughness and hardness is almost perfect. Even Cape Buff bones should not be tough enough to hurt this head.   I then tried to do some "regular" target shooting. I knew from experience that I needed something behind the target to stop the arrow, so I put the shelf board behind the target. It looked OK when I walked up.  But closer inspection showed I had an issue.  Here's the back side. The tips of all four broadheads had made it through.  It was a chore getting that mess loose! Now I need to figure out a better stopping system. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

See also: Other broadhead results Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Don, Clearly the buffalo are in trouble. I hope you are hunting at least two bulls. ~Ann  | |||

|

| one of us |

Can only get one where Rainer hunts. I wish I could get two, also. I really just hope I can get close to a bull. Last time I got within 15 yards of a whole lot of buffalo, but no good bulls. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

The broadhead looks very good Don! I am looking forward to your hunt report with them. Can you take a buff cow in addition to the bull? Or is it one buff only? | |||

|

| one of us |

One buff only, as I understand it. I'll be talking with Rainer more, soon. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

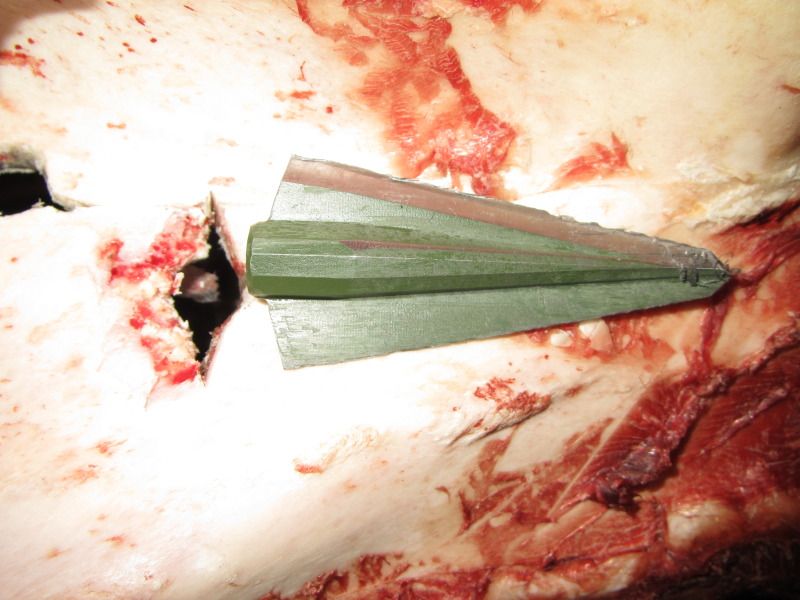

I went to the range this AM. Weather.com promised 4 mph winds, but they were wrong! Relentless 15 gusting 20 mph winds made accuracy impossible. The arrows were all Gold Tip Big Game 200 Kinetic Pros footed with 2.5" of 2014 and fletched with 2.1" feather shields. Total arrow weight: 752 grains. Fired from my 101st Airborne, 73#, 29" at 226 fps, for 86 ft-lb KE, .76 momentum. I took out my box of bones anyway:  The bones were fresh half-pelvis from mature cows and bulls (they were processing for ground beef.) My first shot was low and right, going through a measured .81 inches of bone instead of the thickest portion I was aiming at.  Penetration was clean,with no evidence of skipping or sliding. The bone was cracked and the shaft would slide cleanly in the hole. The broadhead penetrated through the back side of the target, for 15 inches of total penetration. (I measure penetration from front surface to the back of the broadhead, so the point penetrated 18 inches.) The broadhead was undamaged except for some slight waviness for about .25" in the finest feather of one edge. I cannot get it to show in a photograph. Next shot was on the money into the thickest section of a new pelvis:   The bone was cracked from the near end for about 4 inches past the arrow. Actual penetration of 4.4 inches is shown, as the bone was still clamped on the .288 diameter arrow in spite of the .375 diameter ferrule that went through first. The bone was 2.4" thick at this point.  When I sawed the bone down to the crack I could easily pry the bone away from the arrow, as it was held in place only by the connective tissue. I put the broadhead in the wound channel to show some scale. It was only when I was posting this picture that I realized I had it going backwards!  The broadhead was completely pristine. Testing was suspended due to the human element wimping out. That 36 degree wind seemed brutal after several weeks of mild weather! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

what is the cost each going to be and how do we go about getting some? | |||

|

| One of Us |

I love the way that you said "The cow were processed for ground beef." Don't worry Don. We are all hunters here and we all eat meat. I do the same thing when ever I have to write an article here in SA. We always have to justify our actions the moment when we use animal matter for testing. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| one of us |

You'll have to ask Ray@VPArchery.com about the cost. I am not in the broadhead business, and have no intention of starting one. My guess is a couple bucks more each than their 300 grain Penetrator, or the soon-to-be-announced 325 grain single-bevel. The extra cost will be due to the extra work making the required separate stainless steel ferrule. I cannot say enough about how easy Ray and Jeff of VPA have been to work with, as well as the quality of the work. Their stuff is all made and heat treated here in the USA, and the quality and reliability is what you'd expect. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

Hi Fritz, The comment about ground beef was so that everyone would know that these were old cows and bulls with mature, tough bones as well as tough meat. They grind up the tough old guys. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

I hear you Don. I did not know that. I just smiled because here by us we have to explain our self nicely if we want to do something like that to publish. I wrote an article a few years ago about probably the last legal Rhino that we hunted with a Bow in SA. I got so much stick from people that wanted me to justify why we shot the poor innocent rhino. It did not help much when I said that he was not poor and innocent but that he was very rich and guilty. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| one of us |

It's the same here in the US, but since I only "publish" on websites like this, I don't waste any time on "political correctness." I also find the "HIDE POST" option very convenient to aid in ignoring certain "members" who seem to be sheep in wolf's clothing, so to speak. That way I never see their posts, so I am never tempted to give them what they want: verbal ammunition to use elsewhere, out of context. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

I have never posted a pic of the insert. That piece of stainless is very hard to get a picture of. This is the best of a sorry lot.  The ends are .204, the body .199 with .180 grooves. The ends set the concentricity, the undersized middle assures that the epoxy is thick enough to have some strength. The overall length is 2.025, with a body length of 1.700. They weigh 111 grains. Note the tapered support between the body and the threads - this makes the threads less likely to break even though they never take any strain during shooting or impact. This is the attention to detail that Jeff puts into every aspect of the machining. I gave him a cartoon and he gives me back a Mona Lisa! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Very nice work. The trick to photographing very shiny things is to use a polarizing filter on the camera. | |||

|

| one of us |

Yeah, my problem is at a very basic level I don't care much about pics. I seldom (if ever) go back and look at them. So I ain't carrying around any polarizing filters for my cheap ass cameras. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| Moderator |

That broadhead makes me want to hunt dinosaurs with a bow!! Very very cool Don! I expected nothing less from a man with your attention to detail. | |||

|

| one of us |

I can see the trip report now: There I was, nothing between me and a T-Rex but my trusty Dauntless broadhead.... Hold my beer, and watch this! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

No T-Rex's here Don but I shall do my best. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| one of us |

OK I have a few questions. I am not a Bow hunting expert. I have killed 2 deer with the same Mangus Buzzcut broadhed, and arrow, so I am asking the following questions because I want to know... The vector of force of an arrow should be centered on the shaft. SO if you have a 2 bladed broad head, with blades off set to the center of the shaft, it would seem to me that, say if one blade struck a bone it would tend to torque the shaft not only of the central axis, but off the radial axis as well. I think this would effect penetration more than if both blades were aligned with the center of the shaft... DOUBLE RIFLE SHOOTERS SOCIETY | |||

|

| one of us |

I think that if an arrowhead of any type hits anything off center it will violently disrupt the path - a lot. The effect is lessened by a high FOC, which I am achieving - but that is independent of the broadhead design. If you look at the way the edge runs on this head, the EDGE is on an axis of symmetry that runs though the centerline all the way around. On "normal" single bevel heads where the blade center of mass is on the same axis of symmetry the edge is offset on either side of that axis. I'd bet it would take a very detailed study to show that there is no practical difference between the two when only one blade hits bone. EDIT TO ADD: It's like the mythical "brush busting" bullet. Does not exist. Anything other than a direct penetrating hit will cause deflection. I see no ill effects of the offset blades so far, in bone, wood, foam or air. I think it helps the detailed tanto tip design very much, and that's what I really like about it. Ashby talks about "skip angles" for various broadheads, which I think are strongly affected by how pointy and hard the tip is. This offset blade design gives me a well-supported but very tiny tip. VPA thinks the offset blades and centerline edge will help bone-splitting by increasing the effective twisting forces. I can't say one way or another, since I don't have a good comparable. (I'd love to have the funds and time to do a true scientific test series.) Certainly these seem as good as the others I tested - and these don't break. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

You have Rage broad heads for that | |||

|

| one of us |

That's my next design goal - a mechanical head for Cape Buffalo. It will come with a tube of petroleum jelly to reduce collateral damage when the enraged bull jams his horn up your ass! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

Went back to tear up more stuff today - and succeeded. Who knew that bone gets harder as it dries? Now I see why Ashby insisted on carcasses less than 30 minutes dead. First up was a bull scapula. It sounded like a gunshot when the arrow hit the bone.  Got a clean hole, with the bone chipping and breaking rather than splitting like fresh bone. The broadhead had significant damage to the edge.The arrow was intact. Most of the edge was wrinkled, which you can somewhat see in this photo. The broadhead was straight, and could be resharpened.  Being more than a little stubborn I did it again with a fresh broadhead, with similar results.  I then took one of the edge-damaged broadheads and fired it at the biggest leg bone I had. It penetrated like a bullet. Again the bone was chipping like glass and only split on one side.   The arrow was intact and the broadhead straight, so I did it again, aand again got similar results. The edge was getting even more beat up now, with chips along the edge - probably where the edge had been bent repeatedly during the multiple passes.  The tip was still pristine and the body straight, so I fired it yet again at the lower leg bone. This time I intentionally shot at the curving surface, trying to see if it would stick or glance off. It glanced off as though the bone was my old angle iron. It glanced off, went through a few inches of the foam target at a severe downward angle and hit concrete.  The tip was scratched a bit, but still straight and entire. The body was straight, but the edge is toast. I will save it in case I ever try to grind one down to a narrower cutting diameter. I can't say I am overjoyed by the edge damage, but I am very glad that the broadheads adapters and arrows all survived the penetrating shots. I think I have as good a setup as I can get, and started arrow finalization and bow tuning this evening. I think my test-to-failure days are over for a while. Thanks for watching. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Don You are the most dedicated equipment tester I've ever come accross. You should hire your services to some of the big brands so they don't ever get to dump rubbish products on the unsuspecting bowhunting public. JCHB | |||

|

| One of Us |

I have a suggestion for you Don. I did it with a few of my old GK's and I am very impressed with the results although I am no engineer and only have elementary tools. Why do you not take the old/used head and serrate the edges with a backward angle. It cuts sinew and thick skin like a knife does butter. I have also found that it keeps its sharpness longer if the serrations are not to big. Just a thought. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| one of us |

You got to me just in time, Fritz. I'll put the boogered ones in the package, and you can grind on these hard A$$ heads! Thanks JCHB, but most would not put up with any negative info. There's a guy over at ArcheryTalk named Whitey375 that tests more than I do, but with 100/125 grain heads. Cape Buff/elephant/hippo/rhino/giraffe hunters form a niche market that seldom gets any real R&D. Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| One of Us |

Don you're right about the R&D because the market is so small. Almost everyone who hunts the big stuff tests their equipment a lot before the hunt though. If they dont they are damned fools! | |||

|

| One of Us |

Hey Don. I meant for you to do the labor and not pass it on like a good manager/boss. Then you can have another head to torture test. Fritz Rabe Askari Adventures & Fritz Rabe Bow-hunting | |||

|

| One of Us |

Thanks Don for the test info. That looks like one wicked broadhead. I have been using the VPA Terminator broadheads (125 & 150 grain) for deer and plains game for a couple of years with excellent results. Ray at VPA has always been a pleasure to work with. Best of luck with the beasts Don. Andy -------------------------------------------- National Rifle Association - Life Member National Wild Turkey Federation - Diamond Life Sponsor Pope & Young Club - Associate Member | |||

|

| one of us |

DauntlessBroadheadBearShoulders Here's a vid of a bear carcase test. This was the only arrow that stopped in the carcase. It hit both shoulders and the spine. The carcase was from a 19.5" 16 year old boar, in Alberta. I took a good P&Y boar with the Dauntless. Ribs in, ribs and off shoulder out, then buried to the back of the broadhead in a beech tree. No contest! Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| Moderator |

| |||

|

| One of Us |

Don This is the response I got from Ray at VP Archery reference purchasing some of the Dauntless Broadheads. "We made those heads as a custom run for Don. They are not a standard product. It cost several thousand dollars for a production run. We have no plans for making them a standard item. There are some guys on Tradgang that are trying to get enough people together to afford to order a run last I heard." Ray Prillaman Don , thanks for sharing all of your testing and research. You truley are the "Spideman" of Bowhunting!! Shane | |||

|

| one of us |

Here's a pic of the bear, for those who don't visit the Canada Hunting forum.  Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| one of us |

Fritz asked me to post these pics of a wildebeest he shot. I doubt they are in the right order, but here they are. Fritz will explain.    Don_G ...from Texas, by way of Mason, Ohio and Aurora, Colorado! | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Hunting

Hunting  Bowhunting

Bowhunting  The Dauntless custom broadheads are here!!!!

The Dauntless custom broadheads are here!!!!

Visit our on-line store for AR Memorabilia