The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Something I noticed on my 7mm Rem Mag brass

Something I noticed on my 7mm Rem Mag brassGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

Was going through my 7mm brass last weekend, and noticed something that concerned me a bit. I have 140 cases, that have been fired three times. About half were fired with a load of 64.8 gr of H4831 SC, with a 139 gr SST slug. The others were loaded with a 154 gr SST and 60.9 grs of H4831 SC. Both loads are just under the Hornady book "Max load", and have been worked up safely. There were no pressure signs (flat or cratered primers, etc) in the previous two loads. When I was polishing the brass, I noticed that just above the belt on the case, there was a series of small cracks going around the case on 10 of the 140 cases. There was no carbon (I caught this as I was adding the cases to the polisher) on the outside of the case. My question is this. Is this something I shoud expect with a 7mm Mag? I am going to reduce the powder charge on both bullets, but would like to see what you all thought also. | ||

|

| One of Us |

belted cases are famous for this. about 5 loads are all you get even with neck sizing and just kissing the shoulder. you gotta give up something to get something. and it's case life versus velocity in the belted magnum's case. | |||

|

| One of Us |

I agree - don't expect belted magnum cases to last for very many reloads. What you see is that the cases have gotten very thin near the belt - you will have a head seperation if you try to use them again. Throw them away. | |||

|

| one of us |

Hey Jack, A few years ago I ran a Case Life Test in a 7mmRemMag Ruger M77 using R-P cases, Rem 9 1/2M Primers, 150gr Bullets and a Safe MAX Load of IMR-4831. Since I do not Hunt in Dangerous Game country, I went with good old P-FLR using Standard Grade RCBS Dies. I used 3-cases and got 33 reloads without any problems at all. After the last 3-shots were fired(99 in total), I noticed a Neck Split on one case. I had not been Annealing the Cases as I ran the test. Perhaps the Chamber in that old Ruger and the Dies just happened to match-up extremely well, so there was not a lot of Case Stretching or Resizing being done. Or perhaps the old P-FLR caused it to work so well. I don't know which, or both, to give credit to. I'd think if you are FLRing your cases though, your results are about normal whether they are Belted or not. Best of luck to you. | |||

|

| One of Us |

Several folks have got near 20 reloads with 30 caliber belted cases using a full length sizing die to reduce most of the body diameter close to the belt and set the fired case shoulder back a few thousandths such as 3 or 4. Then they resized the body with another full length sizing die cut off just below the shoulder and 1/16th inch above the belt clearance counterbore at its bottom. Setting this die in the press so the bottom of the die just touches the belt reduces the body diameter back to virtual new dimension. www.larrywillis.com has a new version of these old "belted body dies" we used to make years ago. We've got best accuracy from belted cases full length sizing fired belted cases this way. No version of neck or partial sizing came close. Even new cases produced better accuracy than neck or partial sizing. Bart B. | |||

|

One of Us |

Bart Even Larry Willis admits that his die will not decrease the amount of thinning at the pressure ring that causes case head separations, if you want I'll post a link. Why would you bring that up when the original poster was talking about cracks around the case at the pressure ring? Also, anyone else would agree that full length resizing is the quickest way to get case head separations such as are imminent with the original poster. Your tunnel vision on FLR even in this case where you are advising someone else to do it on a belted case is uncalled for and even dangerous if he were to follow your absurd recommendation. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

That comment's based on ignorance. Keep it up and you'll move into the dumb and stupic catgegory. If it was absurd, I wouldn't mention it. Because it's been very successful with folks who do it, I mentioned it. There are those who think your comment's uncalled for, too. Bart B. | |||

|

| one of us |

If anyone believes this line of bologna, I'd encourage you to run a short Test of your own as Bart's Twilight Zone style Reloading Technique will quickly show you his suggestion is absurd. Again, the same Test can be done by having a buddy hand you the Cases so you do not know which type of Resizing has been done. Doesn't take many cases, even 6-10 of each style should show you. Then you can sit back, look at the thread and laugh along with me at Bart's post. | |||

|

One of Us |

I think I'll let you occupy that category all by your self Bart. The original poster was worrying about cracks at the pressure ring and you are advising him to full length resize? The most sound advise would be to headspace on the shoulder which is Partial Full Length Resizing. It is common knowledge, so common that it is not in question, that Full Length Resizing will cause repeated stretching at the pressure ring and lead to case head separations and that the best approach is to headspace off the shoulder. Case head separations can be dangerous and you should be called on this for giving dangerous advice. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

They are already heading to the brass recycle bin. Going back through my notes, I suspect the ten cases in question were part of a box of factory loads that I had bought to test the rifle while waiting for new dies. So that would make four firings, not three (my wife "cleaned" my reloading room one day, and the spent factory cases ended up in my reload bag). I have a Redding NS only die, and have been using that after the second firing. Also, I have been keeping an eye on the case length, and did trim the cases after the first firing (which is standard for me). My real question is this a sign of a head space problem? When I bought the rifle (used at Gander Mountain), the gunsmith checked it with a set of "Go/No Go" gauges, and it was ok. I can't see what would make it change in the year since (it is a Savage 116). For right now, I will keep an eye on the rest of the 50 loaded cases, and see what happens. | |||

|

| one of us |

I bought a bag of new Remington brass and reloaded them about five or six times and then bought another new bag because I had heard that belted mags ate brass quickly. I have my FL die adjusted out enough to where I just feel a slight resistance to closing the bolt. The second bag of Remington brass is still unopened after three years and I'm on about 20 reloads on the original cases. I guess I got lucky as my chamber seems to be cut correctly. Frank "I don't know what there is about buffalo that frightens me so.....He looks like he hates you personally. He looks like you owe him money." - Robert Ruark, Horn of the Hunter, 1953 NRA Life, SAF Life, CRPA Life, DRSS lite | |||

|

One of Us |

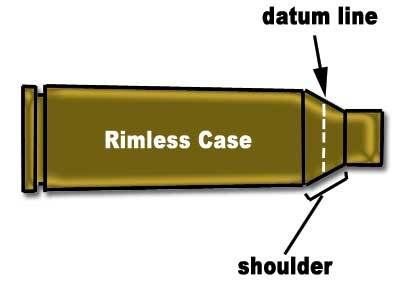

Since this is a belted case, we need to go through the "headspace" and "head clearance" definitions. "Headspace" on a belted case is taken from the front of the belt to the case head. "Head Clearance" is taken from the case head to the shoulder datum line  I believe (never used one) a go-no-go gauge will see if the chamber is correctly reamed by measuring to the front of the belt. This will not identify your problem. What you need to know is the head clearance on your case. IME the brass manufacturers are not concerned with the amount of head clearance on belted cases and sometimes there is a huge gap between the case shoulder and the chamber shoulder even when the case is fully seated forward to contact between the front of the belt on the case and the belt groove in the chamber. For instance I took the following measurements on the head clearance on new cases with the Hornady Headspace Gage which take measurements to the datum line  rifle / new case / fully expanded case / head clearance Mato 338 win mag / 2.0970" / 2.1240" / .027" Sako 300 win mag / 2.2530" / 2.2735" / .0205" Mato 300 win mag / 2.2530" / 2.2725" / .0195" Pre-64 264 win mag / 2.109" / 2.1385" / .0295" Win 70 264 win mag / 2.088" / 2.1290" / .0410" Custom 6.5 rem mag / 1.768" / 1.785" / .017" Now the 6.5 rem mag was a custom rebarrel that has zero (0.000") headspace when I measure a case chambered and seated to the belt, but it still has to expand that .017" to the shoulder when fired. It could be said that the head clearance problem with the belted mags is as much a problem because of the brass manufacturers as the rifle manufacturers. Case head separations caused by thinning at the pressure ring are more dependent upon the amount of "head clearance" you have rather than the amount of "headspace" as measured with the go-no-go gauge. So the answer to your question is that your headspace could be fine but you could have too much head clearance and that is causing your problem. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

When I had a 7rem mag, this is how I loaded it & got 10 reloads before I pitched the brass. Partial or neck sizing is std. procedure for any bottle neck, belted case IMO. LIFE IS NOT A SPECTATOR'S SPORT! | |||

|

| Administrator |

As it has already been pointed out, this a problem with generously cut chambers in belted magnums. I really have no idea why manufacturers and gunsmiths have not learnt how to avoid this. Years ago, a good friend of mine told me that one should NEVER cut the chamber so that the GO gage fits. He said by that time the chamber is too large. His recommendation was to use a new case as a headspace gage. One cuts the chamber, so that the case would just fit, and stop. The GO gage would NOT fit in it. We have been chambering all the belted rifles we make by this method, and have never had any factory ammo refusing to feed and fire. The benefit, though, is that each case lasts a lot longer now. | |||

|

| one of us |

Here is a picture of a headspace quage for a belted mag in this site http://www.rifleshootermag.com...hing/headspace_0612/ Forester make a field length gauge for each mag cartridge beside the go and no-go quage. VFW | |||

|

| one of us |

Hey Jack, I doubt you have a Headspace problem, just FLRed them, which caused the Stretching at the Pressure Ring(Insipient Case Head Separation) to begin with. If you would take the time to Fire Form the new Cases with the cheapest Bullets you can find, using a mid-range load(if that level is OK in your rifle), with the Bullets Seated 0.010" Into-the-Lands, then begin P-FLRing, your problem should go away. Same with Necking-Up the Case and then P-FLRing so it is a snug fit as the Bolt closes will prevent "most" of the Insipient Case Head Separations. And if you prefer NSing, it should do fine after Fire Forming too. Use the old Bent Paper Clip trick to create a Feeler gauge and see if there is a groove inside the Case at the Pressure Ring. Sharpen the tip by cutting it off with a pair of side-cutters. Our esteemed Mr. Woods might have a flick about this in his bag of goodies. ----- Hey Woods, That looks like one of them "Thingys" on your calipers. Send the mess to me and I can get it off for you. Who in the world taught Bart to reload? Sierra? Bobby Tomek? Rod Stirling? | |||

|

One of Us |

A rifle with "generous" head to shoulder dimensions can cause this. The secret is to use cases that headspace on the shoulder, not the belt. "Bitte, trinks du nicht das Wasser. Dahin haben die Kuhen gesheissen." | |||

|

| One of Us |

Woods exclaims: I'll stop giving the same advice (that ain't dangerous as you say) as reloading die company's give just as soon as you make them stop. Check their web sites and instructions packed with their full length sizing dies. They say to set the die lower than I do that'll set the fired case shoulder back more than I suggest. Why don't you march around their offices protesting what they tell the world? Take 'em to court. Make 'em stop saying what I do. I doubt you'll do that as it ain't near as much fun as picking on me. If you tried, you'd get the same results from them as you get from me. You probably already know that. So continue your rants against me and the ignorant will cheer you on. Bart B. | |||

|

| one of us |

Don't mind Hot Core. He's just being himself, which is the quintessential jerk. When he can't add anything legitimate to a discussion (which is quite often), he resorts to name calling and incessant capitalization. He isn't bright enough to figure out for himself which .22 caliber bullets are least likely to give ricochets, and his rants on CHE have garnered the attention of at least one major player in the bullet manufacturing game -- and let's just say he was the butt of numerous jokes there when the thread was printed out and posted on a bulletin board. His recent knowledge of that really burned his toast as he is the self-proclaimed expert of everything firearms-related . Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| one of us |

Well, let's see, I have a couple of 300WMs, a 7mmRM and a 375H&H. I full length resize all of them and get neck splits before I get separation just above the belt. The 300 WM's have been loaded at least 10 times, and the 7mmRMs about 6 times. I just don't keep track, I examine the cases. Having said that, all my loads are accuracy loads and not necessarily max loads. Peter. Be without fear in the face of your enemies. Be brave and upright, that God may love thee. Speak the truth always, even if it leads to your death. Safeguard the helpless and do no wrong; | |||

|

| one of us |

Gotta agree when I asked if Bart was taught Reloading by Bobby, I did consider it reallllly bad name calling. And correct that I did ask what the "current" least likely to go bouncing off into live-stock would be. Just haven't tried a lot of new Bullets in te past few years. Really appreciate Bobby bringing this one up GLOAT since CHE trounced all over the totally worthless Haphazard SGSs in this excellent thread. GLOAT So, the boys at the Bullet Mfg are being laughed at now GLOAT due to their ignorance. Strange it has never been mentioned who that set of fools happens to be though. Total Lie. I've never claimed any such thing. But, lying to make a fool of himself is a new bottom feeding level for bobby. He must have learned it from "his hero" and close personal buddy teanScum. | |||

|

| one of us |

Hot Core- For the VERY last time, CHE -- as you have been told by countles others -- is nothing more than a tool and far from the final word in pressures. I never compared it to any strain gauge (that was something you dreamed up in your little mind). The are many factors and variables in reloading, and successful loading requires both common sense and logic. You continue to praise it as the greatest thing since sliced bread. Both for those of us who are several rungs higher on the evolvement ladder, we'll take CHE for what it is: nothing but a tool in a game where many OTHER factors must be considered for both safe and successful reloading practices. Bobby Μολὼν λαβέ The most important thing in life is not what we do but how and why we do it. - Nana Mouskouri | |||

|

| one of us |

Hmm. Thanks. That gave me some more to think about. Also thank you Tom Holland. I just thought that since the 7mm Rem Mag headspaces on the belt, that would be the major factor. Should have also thought of datum line, but this is my first belted cartrige. And yes, the go/no go gauge for a belted cartrige only measures the clearance to the belt, not the whole way. Talked with the gun smith over lunch and he gave a very similar story to what you both said. Is there any way to limit this? I am going to just Neck size from now on, but besides that it looks like the only other thing would be a new barrel. | |||

|

| One of Us |

I'm with Fjord. I treat my belted cases just like my standard rimless cases and set my f/l die up for the case to headspace on the shoulder and I reload them until I start getting neck splits --life is to short to anneal cases-- or I get tired of looking at them. I don't count the number of reloads I get but it's a lot. I've never had a case sepeation. And, FWIW, I don't go poking around in cases with bent paper clips. If I want to see what a case looks like inside, I split one lengthwise. The idea of cutting dies in half and running a case thru multiple sizing dies just to shoot the damn thing makes my head hurt. The only way I can make it stop is to take out a Lee Loader and spread its contents on my desk and KNOW that is all I really need to reload a cartridge. ALL OF THE REST is whistles and bells and BULLSHIT. | |||

|

One of Us |

There are 2 ways I know to get past excess head clearance in a belted mag: Take a case with the shoulder further forward and resize it to the smaller case-head-to-shoulder dimension. For instance with a 7 mag you could take a 300 win mag case and resize it to 7 mag with your sizer set to leave the shoulder at the exact dimension of your chamber. That would put a lot of stress on your case, lead to thicker neck brass, lead to a lot of runout and you would have a different head stamp. But it would prevent thinning at the web with the initial firing. The other way was with a die that Hornady used to make, a hydraulic form die. Don't know if they still make them. Essentially it was a die you set up in your press and filled you case with water (I think) and press a tight fitting mandrel in the case neck and give it a good lick with a hammer. The hydraulic pressure expanded the case, including the shoulder. You sent Hornady a fully expanded case and they made you one. I don't think they were cheap, about $150.00 or so. Anyway, neck sizing until you get a crush fit and then Partial Full Length Resizing is the best you can do in a normal situation. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

That IS the problem. Most belted rounds DO NOT headspace properly on the belt. It's why you get excessive case stretching in SOME belted mags. If the chamber is a bit sloppy, the round will headspace on th ebelt & stretching will occure. Just resize like any rimless case, partial or neck size, & your case life will be extended. LIFE IS NOT A SPECTATOR'S SPORT! | |||

|

| one of us |

For many years I did what fred338 mentioned always seem to be more attention paid to that brass needed a wire to check for the start of case separtion etc. I started having barrels replaced and headspace was set on the shoulder with a case as Saeed mentioned for my mag calibers. Today with the cost of brass if you have a sloppy chamber doesn't take long for a new barrel to pay for itself over the life of that barrel. If you don't shoot alot then may not be worth it. VFW | |||

|

| One of Us |

The only practical solution is the tried and true partial neck size until bolt is stiff to close/open then just bump the shoulder back until case snuggly closes with bolt. On new cases you can seat the bullet into the lands and use a load to fireform the new case to try and minimise stretching in front of the belt. Then partial neck size thereafter. | |||

|

| one of us |

Glad to hear it. You were harping on about something you know nothing about. Not sure I said "you" had ever done anything constructive. Of course the definitive Test on how good the always-faithful, never fail, good old, time proven, repeatable, inexpensive EGE, CHE & PRE - was done in the above link. It easily explained how overwhelmingly the CHE destroyed the non-calibrated, guessed at dimensions, and fudge factored Haphazard SGSs - for useful data. I can see where that would leave you out. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Something I noticed on my 7mm Rem Mag brass

Something I noticed on my 7mm Rem Mag brass

Visit our on-line store for AR Memorabilia