08 August 2007, 13:46

EXPRESSTurning for radius under Picatinny rail?

Hi, I've seen some of Westpacs' work building Picatinny rails and would like to have a shot at it too. I'd like to see how the man sets up the lathe for this operation, would you mind showing us how you set the workpiece for this job Westpac?

A picture is worth a thousand words, I am finding so many machining tasks easier to understand through pictures rather than the sometimes complex instructions given. Hell, I don't even know what all of the parts, jigs and general turning & milling equipment are called.

Thanks, in advance for any help.

08 August 2007, 23:24

butchlambertYou can clamp your metal in a mill vise and cut it with a flycutter set at the right radius. You will have to cock the head.

Butch

08 August 2007, 23:35

Jim KobeThere is a formula for that using the diameter of the cutter used and the radius desired.

09 August 2007, 00:39

WestpacI do the majority of my radius work on my lathe. I use an adjustable boring bar and a Palmgren milling vise for the lathe.

The boring bars that I use, take inserts which you can adjust the amount the inserts extend out allowing me to machine the exact radius needed.

If I need to, I can swing and hand feed the compound to machine a tapered radius. Hope this helps...

10 August 2007, 15:54

LongshotThere have been a couple of very good post to this thread. It shows there are many ways to skin the preverbial cat. Thanks guys for sharing your methods.

I do mine the way Butch suggested, but I have learn something new everyday.

Longshot

10 August 2007, 16:35

Marc_StokeldMalm-

I do this with a boring head in the mill, which of course is the same thing as you do but rotated 90°. Why do you do it in the lathe? Is it quicker to set up or something?

10 August 2007, 16:44

WestpacSet up is a lot quicker. You essentially turn your lathe into a horizontal mill, and you don't have to re-indicate the head, which can save a lot of time.

11 August 2007, 03:51

Alan WarnerChrist!:

Just trig the layout coordinates using a ball end mill and lap to finish.

Takes all of 12 minutes to do the math, and 4 minutes of cut time using 2 degree increments of movement for each step. 10 minutes to program, or 20 to cut it manually.

Alan

11 August 2007, 20:45

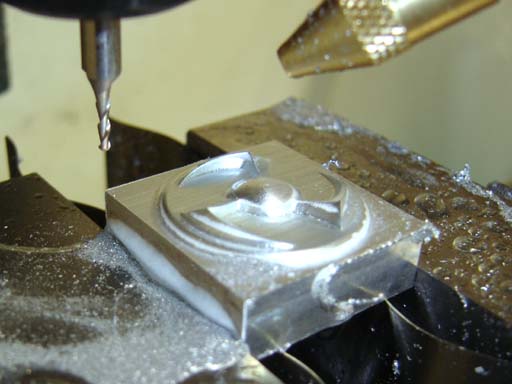

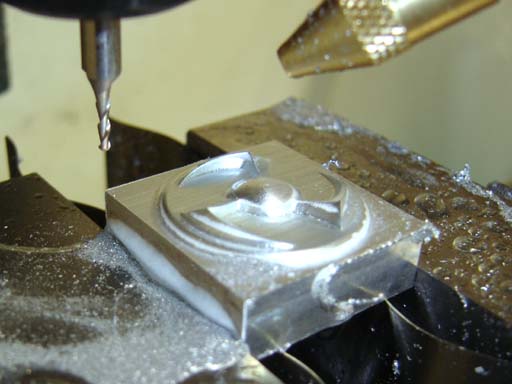

ireload2Example of ball end mill (Keller) profiling