The Accurate Reloading Forums

5/16 Annular cutters

15 June 2015, 19:22

D Humbarger5/16 Annular cutters

Can't find one that small a diameter. Speerchucker where do you get your 5/16" annular cutters?

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

15 June 2015, 22:00

speerchucker30x378If you want them for bolt handles the core size is whats important. It has to cut a 5/16th core. Some of the 1/2 inch cutters will. But you would have to check them.

I use the 5/8ths OD annular cutters. They will leave a 5/16ths core. I use both the Norseman and the Milwaukee brands. The Norseman cut a way nicer than the Milwaukees. I think Fastnell and most of the tool companies carry them in the USA. I buy them from Greggs Distributors here in Canada.

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years!

Rod Henrickson

15 June 2015, 22:08

D HumbargerThanks. I appreciate the info.

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

15 June 2015, 23:05

sliversPiloted counter bores work well. Available from MSC Industrial Suppply.

15 June 2015, 23:26

speerchucker30x378quote:

Originally posted by slivers:

Piloted counter bores work well. Available from MSC Industrial Suppply.

Had me going there for a second. You mean REVERSE COUNTER-BORES !

How the hell do you hold them? If you just used a 1 inch diameter you could lock it right in the collet and cut the whole knob away in one shot. But it would generate a lot of cutting pressure. Might bust off the bolt handle. And they are a bit dear at $85 USD. That's about 2 million Canadian or am I missing something here?

http://www.mscdirect.com/product/details/09937426http://www.mscdirect.com/brows...=12106110+4288194057

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years!

Rod Henrickson

16 June 2015, 01:23

kcstottI have a fixture that I made that chucks up in the lathe I can turn the knob off as fast or a slow as i like.

www.KLStottlemyer.comDeport the Homeless and Give the Illegals citizenship. AT LEAST THE ILLEGALS WILL WORK

16 June 2015, 04:39

J_ZolaI would think for one or two a boring bar in the mill would work well.

16 June 2015, 17:23

Jim Kobequote:

Originally posted by J_Zola:

I would think for one or two a boring bar in the mill would work well.

That's how I do it, rough it out with an endmill first.

Jim

Jim Kobe

10841 Oxborough Ave So

Bloomington MN 55437

952.884.6031

Professional member American Custom Gunmakers Guild

16 June 2015, 17:50

sliversquote:

Originally posted by speerchucker30x378:

quote:

Originally posted by slivers:

Piloted counter bores work well. Available from MSC Industrial Suppply.

Had me going there for a second. You mean REVERSE COUNTER-BORES !

How the hell do you hold them? If you just used a 1 inch diameter you could lock it right in the collet and cut the whole knob away in one shot. But it would generate a lot of cutting pressure. Might bust off the bolt handle. And they are a bit dear at $85 USD. That's about 2 million Canadian or am I missing something here?

http://www.mscdirect.com/product/details/09937426http://www.mscdirect.com/brows...=12106110+4288194057

Ever heard of an interchangable pilot counter bore? Some take a 5/16" dia. pilot. Held in a milling tool holder or collet. Cut the knob off with an abrasive wheel. Work under flood coolant to keep the heat down. Threaded section ends up being 3/8"-7/16" long. I'd opt for the lathe fixture, but I just don't do enough of them to justify the cost. Interchangable piloted counterbore $45-$55. Use your head, don't get 'wild' with it. They look about the same as your slugger cutters.

16 June 2015, 19:01

speerchucker30x378quote:

Originally posted by slivers:

quote:

Originally posted by speerchucker30x378:

quote:

Originally posted by slivers:

Piloted counter bores work well. Available from MSC Industrial Suppply.

Had me going there for a second. You mean REVERSE COUNTER-BORES !

How the hell do you hold them? If you just used a 1 inch diameter you could lock it right in the collet and cut the whole knob away in one shot. But it would generate a lot of cutting pressure. Might bust off the bolt handle. And they are a bit dear at $85 USD. That's about 2 million Canadian or am I missing something here?

http://www.mscdirect.com/product/details/09937426http://www.mscdirect.com/brows...=12106110+4288194057

Ever heard of an interchangable pilot counter bore? Some take a 5/16" dia. pilot. Held in a milling tool holder or collet. Cut the knob off with an abrasive wheel. Work under flood coolant to keep the heat down. Threaded section ends up being 3/8"-7/16" long. I'd opt for the lathe fixture, but I just don't do enough of them to justify the cost. Interchangable piloted counterbore $45-$55. Use your head, don't get 'wild' with it. They look about the same as your slugger cutters.

OK I found them. You just pull the pilot stem out of them. They are about the same price as annular cutters and would probably work OK except for the the side torque from the flat cutting faces if they were used without the pilots. Good annular cutters don't cause that problem because of the reversed cutting angles on the teeth. They actually pilot on the center of the cut. Not on the stub they make as some people think. So once all the teeth start to bite they stop trying to squirt from side to side.

I used to do them in the lathe and then switched over to a boring head in the mill. The only problem I had was the time it took and I did break off a few handles. A guy I know in Europe clued me into the annular cutters as being quick and reduced torque.

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years!

Rod Henrickson

07 July 2015, 06:29

D HumbargerSpeerChuaker in your utube video on useing the annular cutter to machine the 700 bolt knob,where did you find that "C" shaped feeler for theindicator?

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

07 July 2015, 06:52

speerchucker30x378quote:

Originally posted by D Humbarger:

SpeerChuaker in your utube video on useing the annular cutter to machine the 700 bolt knob,where did you find that "C" shaped feeler for theindicator?

I probably made it out of a chunk of drill rod. I have a whole box full of home made feelers for the coaxial indicators for doing odd ball engine cylinders and parts. I have some super long ones for finding center on parts that are a couple feet in diameter. Have need, will make, make em, throw em in the box, forget what they are for. LOL

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years!

Rod Henrickson

07 July 2015, 18:03

D HumbargerThat what I suspected. Thanks for the quick reply.

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

08 July 2015, 06:24

D HumbargerBy the way how many rpms are you spinning your annular cutter?

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

08 July 2015, 09:27

speerchucker30x378I generally turn them at about 100 RPM. Bolt handles are often pretty tough material and the stainless ones will often work harden so I give the cutter just what it wants and turn it slow to avoid over heating and dragging the tool without cutting.

I have used water in the passed but heavy, sulfur cutting fluid cuts smoother, with less force and the cutters go longer between sharps. Those annular cutters are a pain to sharpen too. I can't remember off the top of my head. But there are something like 16 separate grinds to each one to resharpen them. It's almost not worth putting them in the Cuttermaster grinder.

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years!

Rod Henrickson

08 July 2015, 18:09

D HumbargerYep those bolt knobs are tough. I've found the Win M70 the toughest so far. I appreciate the info. Will post some photo of my set up when I get a chance.

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

09 July 2015, 20:34

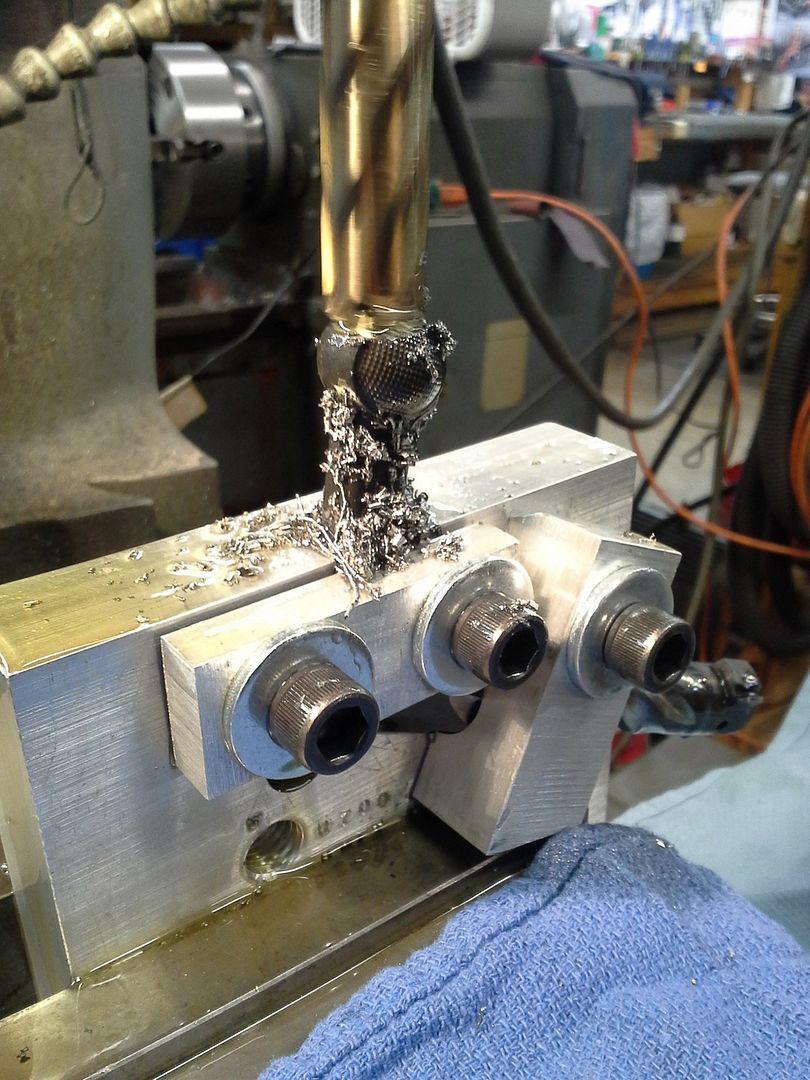

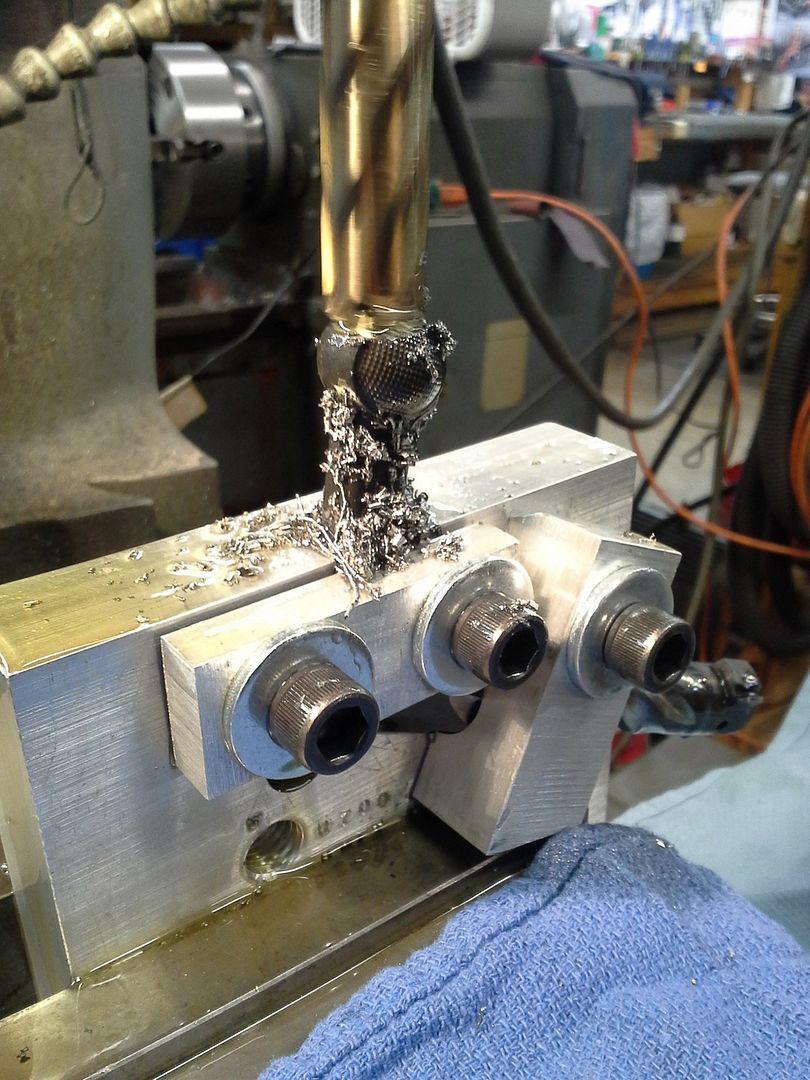

D HumbargerThis is my set up. I made a simple bolt holding jig to secure the bolt. I tilt it to what ever angle I want the knob to be at. Thanks for the advice on the Norseman cutter. It really makes a nice clean cut. Started out at 80 rpms then after getting through the tough shell sped it up to 125 rpms to finish the cut.

Doug Humbarger

NRA Life member

Tonkin Gulf Yacht Club 72'73.

Yankee Station

Try to look unimportant. Your enemy might be low on ammo.

10 July 2015, 01:09

speerchucker30x378They do cut like the dickins don't they.

Get some heavy Ridged or dark Sulflo cutting fluid. Cutters last a lot longer with it. Been there. Done dat. Go that T shirt too. LOL

When I was a kid. I had the stick. I had the rock. And I had the mud puddle. I am as adept with them today, as I was back then. Lets see today's kids say that about their IPods, IPads and XBoxes in 45 years!

Rod Henrickson