The Accurate Reloading Forums

Smih and Wesson Yoke Screw fitting

04 August 2016, 02:21

airgun1Smih and Wesson Yoke Screw fitting

I had either a website, you tube video or some detailed information on how to properly fit the Yoke retention screw (lower right side plate screw) on a Smith and Wesson K frame from the 1930's - 1960's+. These required fitting not the later spring loaded plunger type.

Can anyone set me straight?

PA Bear Hunter, NRA Benefactor

04 August 2016, 05:33

Toomany ToolsIf it's too long and binds the yoke, make it shorter.

John Farner

If you haven't, please join the NRA!

04 August 2016, 07:42

ScrollcutterThe fitting would be on the button of the yoke. Does the yoke move for and aft with the screw in? If so, the button on the yoke would need to be gently peened toward the screw until the screw is rubbing on the button.

If it's too tight, the button would need to be filed where the screw is rubbing.

Properly fit, there should be no movement for and aft with the yoke closed. The filing should taper so that the yoke slightly loosens as it opens. Very light on with the file or with the hammer. Make sure if you peen the yoke that you support the front of the yoke with babbit or a lead bar. Don't want to spoil the finish.

Good luck.

Roger Kehr

Kehr Engraving Company

(360)456-0831

04 August 2016, 07:49

Toomany ToolsJust what I said, Roger!

John Farner

If you haven't, please join the NRA!

04 August 2016, 08:20

RollandYabut you didn't use as many words as he did

Never rode a bull, but have shot some.

NRA life member

NRA LEO firearms instructor (retired)

NRA Golden Eagles member

05 August 2016, 01:10

airgun1Yoke fit is just fine. I want to replace a buggered screw is all.

PA Bear Hunter, NRA Benefactor

05 August 2016, 01:33

ScrollcutterThe new screw is a fitted part. It may fit just fine...or it might not. Due to manufacturing tolerances each screw will be slightly different.

Anybody that knows John Farner, knows that he is a very competent gunsmith. He doesn't need any guidance from me. Everybody knows there is more than one way to skin a cat. But if your new screw doesn't fit, the instructions above are how Smith and Wesson does it.

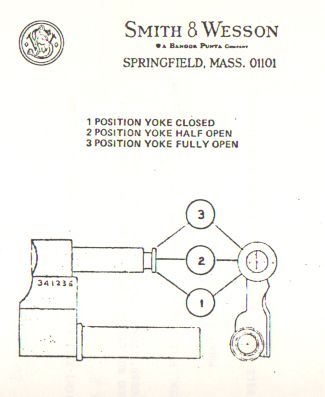

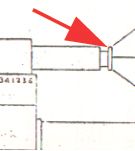

Here's an illustration out to the Smith and Wesson armorer's manual to show where the fitting work will be done.

The file work would be cut at about a 45 degree bevel where the arrow is pointing. Best to use a 0 or a 00 cut on a barrette file.

Roger Kehr

Kehr Engraving Company

(360)456-0831

05 August 2016, 03:58

J_ZolaThanks Roger

05 August 2016, 06:36

Toomany ToolsThanks, Roger. Sometimes I like to tease.

John Farner

If you haven't, please join the NRA!

05 August 2016, 07:40

airgun1Wow, thanks a million.

PA Bear Hunter, NRA Benefactor

05 August 2016, 07:54

ScrollcutterI can take a joke. Consider me teased. Heh

Roger Kehr

Kehr Engraving Company

(360)456-0831