The Accurate Reloading Forums

Good inletting for an amateur

21 May 2014, 09:57

pennflyGood inletting for an amateur

Trax that borders on just being an asshole.

Trax

If you knew anything about manufacturing and had ever done anything other than cut and paste photos you would be complementing him on his ingenuity.

quote:

Originally posted by Trax:

quote:

Originally posted by Duane Wiebe (CG&R):

Jeez Trax: Let me try and make this simple: I do not use glass, putty, etc. I do not make "patterns", I do not have a panograph (duplicator)., so therefore have no need for glassing up a stock pattern for individual baralled actions.

Yes, occasionally a semi inleted stock is used ....but only when there's a compelling reason and a customer mandate.

I know my method may seem outdated so some, but I have no reason to do it any other way

I was just wondering why you stick to traditional methods for the stocking process,

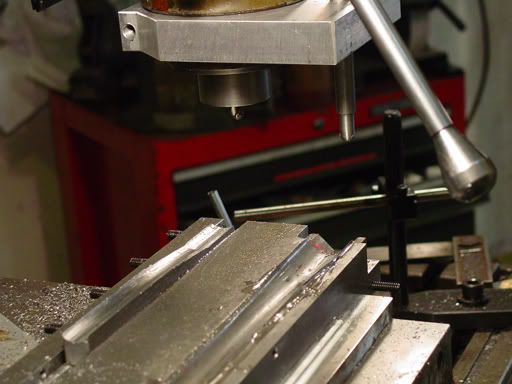

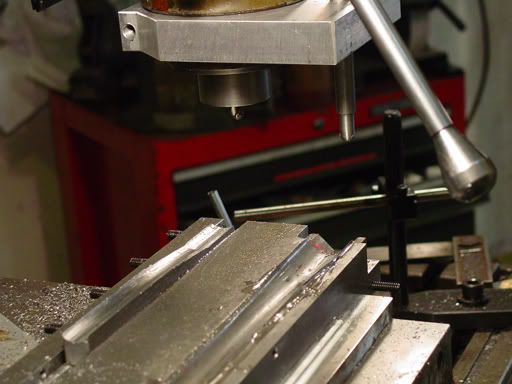

but will employ the convenient use of modern epoxy to mould or cast models to help produce precision metal components.

Just so you know what I am referring to,...

This is your Devcon epoxy created moulded pattern that your machine is duplicating in reverse? ..or am I mistaken?

Trax is best enjoyed on ignore.

Mike

21 May 2014, 19:15

Beretta682Equote:

Originally posted by MJines:

Trax is best enjoyed on ignore.

+1

My peeve is when people copy this comments in the reply and I have to read and look at them.

Mike

21 May 2014, 23:10

AtkinsonDuane,

that speaks highly of your skill of which I have no doubt and brake or no brake you did it all right to survive a Lead sled if it was weithted down,

The big bores wreck havoc "over time" on wood I have no doubt about that, and the climate change from Idaho to to Selous is tramatic on wood IMO. Wood, even the good stuff, may in some cases shrink or swell, and even though I think end grain is tough stuff if it gets a small gap, then the 500s will work on that until it begins to crack, usually behind the magazine, then the grip and perhaps the recoil lug..I have had one ocassion wherein the bolt release swelled a tad and I could not get the bolt out, so had to take the gun down in camp and releave the well fitted bolt release by shaving wood with my pocket knife, my bad...

Just saying stuff happens for what ever reason, even double rifles have been known to split out and I have seen fiberglass warped from heat on hunts on two ocassions, there is no perfect marterial that I know of. Thus the reason I have used glass on "my larger bores", all of which are strictly hunting rifles with very straight grain and proper lay out wood and in some cases laminated glass bedded wood. May not have needed glass with the extra recoil lug on the barrel and the two cross bolts but I was not willing to take the chance, after what I have seen. Seems to be good insurance since bad things only happen when you do not take precautions. there can be a lot at stake.

Not taking a stand on this discussion one way or the other, just discussing a subject..

BTW, my 404 is not glassed, nor is my 338, or 375 H&H Win mod. 70, and they have been to hell and back, I worry more about airline damage than the stock splitting out.

Ray Atkinson

Atkinson Hunting Adventures

10 Ward Lane,

Filer, Idaho, 83328

208-731-4120

rayatkinsonhunting@gmail.com

Amazing! I never thought of slightly relieving the wood at the central part of the recoil lug mortise to concentrate the recoil force at the stronger outer corners, but it makes perfect sense. Of course, I would not really want to shoot a rifle much that kicked hard enough to warrant it!

Buy the Wiebe .500 Jeffery that George Caswell just listed (not mine) and you can check out the inletting first hand.

http://www.champlinarms.com/De...GunID=2647&StyleID=2

Mike

22 May 2014, 07:58

dave wesbrookDuane pretty much covers the recoil absorption areas of the inletting so there is nothing else that I can add to that. ...Several posts ago Dempsy ask how you knew when to stop removing the inletting black. The answer is simply that you stop when the entire barelled action is inletted to 1/2 depth. On a Mauser this dimension is approximately 0.645" from the top line of the stock to the bottom flat of the action. A quick check of this is that the top line of the stock should bisect the ejector cut in the rear bridge of the action. Inlet the entire bottom flat to this depth. Measure the front ring the action, the barrel shank and the barrel just behind the forearm tip and divide by 2 to get those 1/2 depth measurements. ...On a Mod70 the benchmark is the bottom of the gas escape hole on the right side of the front ring. Measure back from there to get the flat behind the recoil lug and the remaining flat along the magazine mortice to the back of the flat under the rear tang. ( Note that during the blueprinting of the action I have the back of the recoil lug milled perfectly square with the action and also have a light cut taken to level and straighten the rear flat.)The Winchester name on the left side is just above the top of the wood. ...Now, for the removal of the inletting black. First I use an acid brush to apply a coat of inletting black to the metal.I brush this out as evenly as possible and seldom add any additional black,but rather keep brushing out the initial coat untill all you have is a very thin,almost a black sheen,on the metal.This gives you a more exacting transfer of the black to the wood. Your first few fittings will only show a few contact points indicated by the transfer of the black. CAREFULLY use a chisel or a scraper to remove only the black only from those areas and then refit the metal into the wood. Each fitting of the metal will show more areas of contact as the metal enters deeper. Go slow and force yourself to remove only a couple of thousandths at a time even though you know that eventually may have to remove MANY thousandths from the same area.The metal will eventually settle down to full depth. (I once counted the number of trial fittings it took to inlet the barrel and action only into a square stock blank. Even though I had blueprinted and scored the outline of every dimension on the top of the blank and cut these in with chisels to within 25/1000 of an inch,it still took me 58 fittings for the barrel and action to settle into final depth.Note that I never counted again.) ...Try to replace and remove the metal without any rocking side to side or front to back as this will result in false markings and transfer of the inletting black. Headless guide screws come in handy here. ...Often you can tell more about the actual transfer of the inletting black by looking at where it is scapped off the metal. A good example of this would be that you see a very thin line of black along the top edge of the front ring inletting. When you examine the metal however you see that the actual contact with thewood started 20/1000" below and the curved side of the ring was actually forcing the wood out slightly. You need to remove wood from the top edge of the inletting. The same applies to all curved surfaces. ...How do you measure 1/2th depth in the barrel channel? Well, the first then that I do is measure the barrel just foreward of the location of the forearm tip.I divide that in 2 to give me 1/2th depth and scribe that measurement accross the tip as a reference depth. I then start deepening and widening the barrel channel using chisels and scrappers. (Remember what I said about curved surfaces and looking at the marks on the metal.) You can tell if you are at 1/2th depth by placing a small square point down in the channel. If the point contacts the bottom as each leg contacts the top edges you are 1/2 the width deep. If you rotate the square the legs should maintain contact with the top edges and the point maintain contact around the entire circumference. ...Hope this helps. Be patient and work slowly. ...Dave

22 May 2014, 17:34

Jim KobeGood one Dave!

Jim Kobe

10841 Oxborough Ave So

Bloomington MN 55437

952.884.6031

Former Professional member American Custom Gunmakers Guild

22 May 2014, 19:09

Evan K.Duane and Dave- thanks for the detailed info. Much appreciated.

"If the women don't find you handsome, they should at least find you handy."

24 May 2014, 00:23

AtkinsonI love these kind of threads on the internet, its a shame we don't have more of these learning sessions..This is some great stuff, thank you Duane and Dave..

I do have a question for you both:

As you know I tend to lean toward the English style of stock, probably because I have been brain washed by Africa and SCI for so many years!

and I abhore to much wood left on any gun!

My question is I tend to allow the barrel and action to ride a tad higher as do many if not most of the European or English guns do..Is this an acceptable practice or is it, not argueable, but worth a discussion.

Also Duane I am going to have to try some your Alkanet root, it seems to be stronger in color than the root I have..I just don't like to work with dye on wood, and the root seems to work so much better and I hate to go back to square one to get color...I also use very dark wood as a rule and alkanet really works on dark wood well.

Ray Atkinson

Atkinson Hunting Adventures

10 Ward Lane,

Filer, Idaho, 83328

208-731-4120

rayatkinsonhunting@gmail.com