The Accurate Reloading Forums

Maybe once and for all--can NP brass scratch dies?

25 September 2013, 05:19

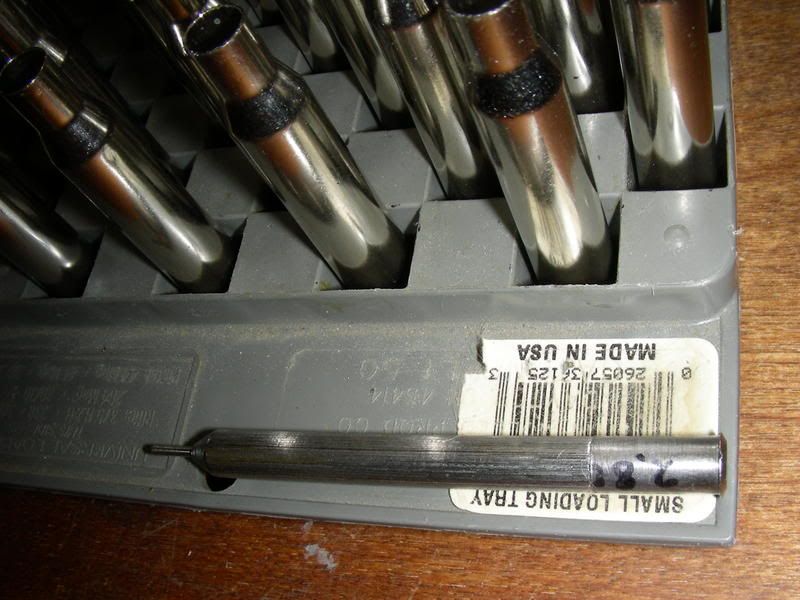

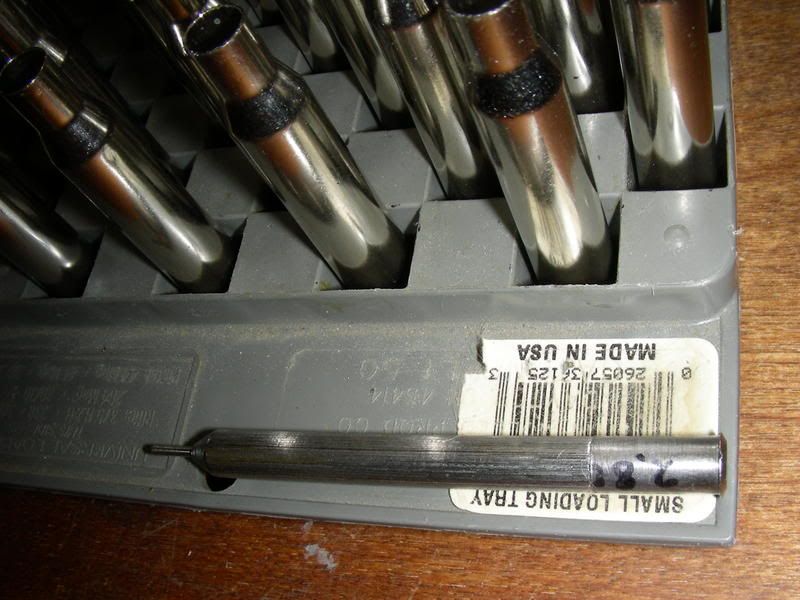

Fish30114Maybe once and for all--can NP brass scratch dies?

I would like people to weigh in who know, I was told a long time ago that the plating on NP brass was not hard enough to scratch dies as it was softer than the metal used to make dies. I have loaded a lot of NP brass and never had an issues, but I would welcome knowledgeable input.

25 September 2013, 05:48

RapidrobNo way can NP brass can scratch a loading die. I have loaded tens of thousands of .38,357mag NP brass and the die is as good as new.

Gulf of Tonkin Yacht Club

NRA Endowment Member

President NM MILSURPS

25 September 2013, 07:54

ted thornThe plating on brass is soft

________________________________________________

Maker of The Frankenstud Sling Keeper

Proudly made in the USA

Acepting all forms of payment

25 September 2013, 12:47

GerryNo, NP brass will not scratch a Die, at least in the RCBS F/L Dies which I use for the cartridges for which I use NP brass; 38 Spl/357 Mag, 25-06 Remington, 30/06 Sprg, 300 WM, 300 Weatherby (all R-P) & 375H&H (Federal).

It will scar both the Dies & the brass though if dirt & grit are not removed prior to lubing & sizing but that goes for any brass that's not clean and run through a sizer Die.

I also use Lee Case Gauge Tools which for me speed the trimming process when used with an eletric screwdriver or drill press. The Lee cutters dull quickly when used on NP brass.

Cheers,

Number 10

25 September 2013, 19:42

LapidaryPhysically impossible. Steel is harder than nickle period. As stated above it is grit stuck to the brass that scratches.

25 September 2013, 20:39

dpcdI know how this false rumor got started; in the dark ages when shooters used a lot of 38 special nickel plated cases,, and dies were not as hard, and shooters didn't clean their brass like they do now, the dirty, gritty brass caused the dies to score inside. Then, after that happened, every piece of brass that went through that die was scratched and I have seen them with striations all over them. This is from personal experience; my Grandfather was a game warden and loaded for all his DNR (Conservation Commission back then) buddies. We had a range out back with the pond dam as the target berm. The old Star loader's dies were scratched all to hell but they didn't care. That was in the mid 1950s.

But is wasn't the brass that caused it. Nickel plated brass just shows scratches well. So, clean your brass and you will never have scratched dies. But now with carbide dies , you won't either.

26 September 2013, 08:59

noyljI have had to clean a sizing die and a Lee FCD die several times due to nickel flaking off and sticking to the carbide insert. It puts "racing stripes" down the cases until you notice and clean the die.

I believe that a hardened steel can have a hardness of around 2000 MPa and Nickel can have a hardness of around 3000 MPa, but I could be wrong.

26 September 2013, 09:51

NormanConquestNo worries on this subject. I hope you have'nt any other concerns. If so take them there ,this one is in the bag.

Never mistake motion for action.

26 September 2013, 15:38

hawkinsA scratch in the die can't scratch the brass.

What happens with nickle plate is that if it

flakes off (usually from the case mouth) it

will stick in the die and scratch the case.

To scratch a case somthing has to be above

the surface of the die. A light outside champher

will avoid problems. Once the nickle is irined onto the die it is a bitch to remive.

26 September 2013, 19:43

Fish30114Good feedback folks, I will consider this one asked and answered once and for all.

26 September 2013, 19:49

StonecreekFor bottleneck cartridges used in bolt rifles I much prefer using the Lee Collet die, particularly for nickled cases. Its squeezing action, as opposed to a conventional die's shearing action, avoids marring the cases when accidental dirt or grit is present. It also does not wear the plating off of the cases as conventional dies tend to do. And best of all, it require no messy lubrication.

03 October 2013, 20:55

Reloader270To prevent NP cases in my .270win to damage my Redding die, I bought a Foster FL die. I use Imperial Wax with the sizing process. I was supprised as how easy the case went in the die and how easy it came out. I am glad to hear that it cannot scratch the die.

04 October 2013, 03:32

woodsI got some 280 WW nickel plated brass since that was all I could find. Like most Winchester brass, some of the necks were dented and the ID's varied, so as typical, I ran a Lee Collet mandrel down the necks to expand and uniform them

ruined that mandrel

Now probably the steel of the Lee mandrels are not "hardened". If the nickel brass was to scratch a regular die, it would do so where the mouth of the case hits the forcing cone up inside where it is not readily apparent. So damage may not be so easily identified

Another opinion

http://www.varmintal.net/arelo.htm#Nickel_Brassquote:

FORGET NICKEL-PLATED BRASS.... I liked the looks and feel of nickel-plated cases, but I don't load them anymore and here is why. The cases are strong and it is easy enough to outside neck turn them. That is not the problem. The nickel-plating on the case neck ID is like sandpaper. The only way you might be able to remove this grit is with a case neck ID reamer if you have a "tight neck" chamber and enough neck wall thickness to work with. If you have a loaded nickel-plated round laying around and don't believe me, just pull the bullet. It will look like you pulled it out of a tube of 180 grit wet/dry sandpaper. If you pull the bullet out of a brass case mouth that has been carefully chamfered and polished with the steel wool process above, it will be essentially like out of the bullet box. Want copper in the barrel? Start by sanding the surface of those nice polished precision bullets. Try it with a Moly Coated bullet and it is even worse; the nickel-plated cases scrape off the Moly. The nickel-plated case neck IDs don't get any better after you reload them a few times. They are still like sandpaper. Think about a few of those nickel pieces of grit imbedding into the copper of the bullet and what they do to your rifle barrel! I have heard that the nickel is hard enough to score some reloading dies and also wear down the expander ball. Any metal that hard, should be kept away from your precision barrel. I have heard that some people have had success in removing the nickel plate from the neck IDs with a stainless steel brush and a drill motor. I haven't tried it.

MORE ABOUT NICKEL PLATING.... This is interesting about the mechanical properties of the nickel plating:

Electrolysis nickel plating is a process for chemically applying nickel-alloy deposits onto metallic substrates using an auto catalytic immersion process without the use of electrical current. ...snip....

Hardness and Wear Resistance

One of the most important properties for many applications is hardness. As deposited, the micro-hardness of electrolysis nickel coatings is about 500 to 700 HK100. That is approximately equal to 45 to 58 HRC and equivalent to many hardened alloy steels. Heat treatment causes these alloys to precipitation harden and can produce hardness values as high as 1100 HK100, equal to most commercial hard chromium coatings. ...snip...

Note that if you anneal your nickel plated necks, you are hardening the nickel plating. It can be harder than many alloyed steels before you anneal and can increase is hardness as much as 2 fold by precipitation hardening. I sure wouldn't want those tiny little hard pieces inside the neck getting embedded in the bullet's copper surface and then fire lapping my nice shiny barrel.

____________________________________

There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice.

- Mark Twain |

Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others.

___________________________________