The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case head Separation

Case head SeparationGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| Moderator |

over worked brass and too much lube... the lube is sealing and causing gas dents. your die is setup 1/2 turn too close for this rifle/brass combination back off on the lube.. here's a hint, unless its a HUGE case, it shouldn't need much lube jeffe #dumptrump opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

| One of Us |

Please explain how lube could cause a dent when the head seperates. Thanks! | |||

|

| one of us |

? | |||

|

| One of Us |

So I took the bull by the horns, and I sent the following note to RCBS tech support:

(I stupidly wrote "case head separation occurred during FL resizing" when I meant "after FL resizing, but I think the reply still stands.) Today, I received this reply from them:

In addition to including the original pictures, I included all the technical information that ALF provided. (As in, I reproduced his post and sent it in its entirety.) | |||

|

One of Us |

That is the trouble with a lot of people and posters. No matter how many times you say it, it doesn't sink in I don't full length resize I don't use too much lube I position the shoulder for PFLR within .001" The explanation for the dent is plausible to me and I will accept it for now. As far as the case head separation I will lay that off to the normal amount of excess headspace common in belted cases that caused the cheap WW brass to thin too much. Perhaps it was an "isolated incident". I would not expect to learn more from RCBS Tech support (as evidenced by their noncommittal response) than I would learn from some very knowledgeable posters here who actually read and try to add to the discourse. Although I use and love their products, I suspect that many here could easily be a supervisor at most reloading company's tech support department (if they wanted to take a pay cut). ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Yeah well, a few years ago some expert wrote in one of our Gun Mags about reloading the 6.5 Swede. He showed photos of large dents, without any head seperation. Reckoned it was common with that cal. and lightish loads, being from gas excaping past the neck. I can't remember any or much soot in the photos either. | |||

|

| new member |

According to the Speer Reloading Manual # 11 page 52, a shoulder collapse just like the one in you photo is a problem common only to magnum rifle cartridges, where there is a lot of free bore in the chamber and a slow burning powder is used. They suggest a faster burning powder. That part is real simple. The rest of it is a chicken and an egg thing, which came first, the shoulder collapse or the head separation? Did a head separation cause the pressure to drop allowing pressure to slip past the mouth of the case and collapse the shoulder before enough pressure finally built up to seal the mouth? Could have. Or did the shoulder collapse make the case difficult to extract and the head separated because the case was stuck? Could have. This is a very interesting case! Please keep us informed as to how all this turns out! The Fight for Freedom is Eternal ! | |||

|

| one of us |

My input is that the chamber should be recut to tighter specs. And your STW is getting just about what I get with my 7MM RM. You are going to be working with high pressures and case head seperations just aren't good. I have no experience with Lee collet dies so I don't know how you could set the shoulder back with them. I have a 30-30 Contender that I fireform with a bullet touching the rifling and this works fine but I am hardly pushing a lot of pressure or gas volume. It looks to me like there is a lot of case expansion in front of the web also. Yeah, get your chamber recut. Leftists are intellectually vacant, but there is no greater pleasure than tormenting the irrational. | |||

|

| one of us |

By the way, those of you who experienced a Case Head Separation, try to get the Chamber as clean as possible and then look it over as well as you can. If your rifle allows it, stick your small finger into the Chamber and lightly touch all around. You are looking for a small Crater or rough spot in the Chamber Wall. You can also do this with a fragile pair of your wife's Panty Hose(or if you are in the Navy, your own Panty Hose) on a snug fitting Patch. You are looking for a spot that Snags the Nylon. The good news is that you probably do not have a problem. When the Case Head completely separated, there is enough area exposed that the Flame Cutting generally does not happen. However, if you are unfortunate enough to get a Pin Hole in the Case Wall, chances are real good that the Chamber got Flame Cut and blew out a small crater. You can see the Pin Hole in the Case Wall easily. And if you have a Crater, you can see the reverse of it on the outside of another Fired Case as both an irregular indent immediately next to a slightly raised spot. This is where the Case formed to match the Crater under the Pressure of Firing. Depending on the strength of your Loads, how many times the Cases have been fired, and if you are Neck Sizing, then the Case might be a bit difficult to Extract as it "hangs" slightly at the Crater. Normally this is not a problem though. But I thought you all might want to be aware of the possibility. Best of luck to you all. | |||

|

| One of Us |

BINGO Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

One of Us |

It sounds like the chamber condition is causing the case dents by one mechanism - powder granules trapped between the shoulder and chamber wall - and another mechanism is causing the case head separation. I have recently come across a number of fired cases from different rifles, with insipient head separation. In my early days of 303 Brit reloading, I got the same thing after only a very few firings. Then a gunsmith told me the trick of leaving the case lube on the loaded cartridge. Twenty five years later, I am still using the same cases. They now only fail due to neck splits. (Yes I know about the wet case/dry case controversy - the 'wet' case will still grip the chamber walls. A polished and shiny case in a smooth chamber is the same as a 'wet' case in a 'not so smooth' chamber. In fact, I have seen a 'wet' case fired in a rifle with serious excess headspace, that did not set back against the bolt face – the primer was still backed out and there were no normal 'sliding' marks on the case). Regards 303Guy | |||

|

| One of Us |

I regularly shoot “wet†cases in my 308 M1a. I don’t tumble off the RCBS case lube, the cases have a slightly greasy feel to them. Learned that trick from a Gunsmith Distinguished HM who shot the same set of 308 cases out of his M1a for the duration of the shooting season. He had been doing that for years. Also do this in my 30-06 Garands. I do not shoot maximum loads, my stuff is 168 Match, 2550 to 2600 fps. I am on the third barrel of my Match M1a, does not seem to hurt anything, and the cases don’t develop case head separations. “wet†cases will not have funny shoulder dents due to lubricant unless you have excessive lubricant. Gas sealing is normal. What this poor guy is having is a common problem with belted cases. Too much shoulder sizing. I recommend that everyone toss out the manufacturer sizing die instructions that come with dies, and set up their sizing with a cartridge headspace gage. This web site is really useful for showing how to use case gages. I recommend looking at the pictures, and it explains the special case gages needed for the belted cartridges. http://www.realguns.com/Commentary/comar46.htm I purchased one of these Sinclair gages for my 375 H&H. I found that even though I had carefully set my dies up using my rifle chamber, to determine shoulder set back, when I was able to measure with a gage what I was doing, I was way off. Yes, in theory if you take the extractor off, take the firing pin assembly out, you should be able to accurately set your sizing depth by feeling bolt closure resistance. And in theory you should be able to set your dies at the point the bolt goes from some resistance to no resistance. However, whenever I have measured cases sized this way, they were always off. I trust gages and use them. | |||

|

One of Us |

In that case, it could be possible for some gas - maybe air - to be trapped in the shoulder free space which could be forced into one spot where it expands back into the shoulder, causing the 'dent', as the chamber pressure begins to fall but is still sufficient to keep the neck and case body well sealed against the chamber? And that is a question - not a statement. Your post is very interesting SlamFire. I know nothing about belted magnums. I'm just very interested in what is happening there. P.S. I normally get 'severely reprimanded' for admitting to lubing my cartridges. Regards 303Guy | |||

|

One of Us |

I can't speak for Alf and he even said that he did not reload the case that separated in his post. However, I do have gauges and I can say with certainty that the case went through the following stages: New case - 2.097" Once fired - 2.120" Twice fired - 2.123" 3 times fired - 2.124" (slight crush fit) 4 times fired - 2.125" (crush fit) This case had been fired 5 times and separated on the 6th firing which means the shoulder was set back to 2.124" for a slight crush fit and PFLR. The proof is that when I fit the case back together and measure the shoulder it is  2.125", which is exactly as I would expect it to grow from a shoulder position on the previous sizing of 2.124". Also, I flitz the cases and they are so slick that they are almost too slick to hold   So we might be barking up the wrong tree. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Woods, does that dent only occur at (or near) head separation? I like your case polishing set up. You have put me up to something! Regards 303Guy | |||

|

One of Us |

The only time I have seen a dent like that was on that one case head separation. I had no explanation and was not positive the dent was related to the case head separation until this thread. Now I am convinced that the dents are a result of the separation although I am not sure that it would happen everytime. My case came out with the extractor and fell apart after coming out of the chamber. Perhaps others where the case stayed in the chamber and had to be knocked out did not pay attention to the dents or attributed the dents to the trauma of mechanically pulling the separated case from the chamber with whatever method they had to use. Flitz is a great cleaner also. If you have old stained cases Flitz is the cure. I mark all my loads on the cases with magic marker to keep me organized. The Flitz does a great job of removing the magic marker. Cleaner than new. flitzed case ...... new case  ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

That is so interesting! I have been thinking about Hot Core's suggestion that it is caused by the escaping gasses as the head separates. At these pressure levels and speeds, let's face it, anything is possible. I can't help wondering whether the dent and head separation are related in that the dent causes the separation? Let's just assume the dent is caused by a granule or two of powder trapped on the shoulder and that 'detonates'. And why not? It gets a massive degree of compression and there would be an amount of trapped air which is compressed to some 60,000 psi which in itself will be pretty hot, not to mention the shock of compression. Well I don't know. I'm not even speculating anymore! Dang! I would like to know what's happening! P.S. Where would those granules of unburned powder come from in the first place? Partially burned maybe? But can a partially burned granule re-ignite? Regards 303Guy | |||

|

| One of Us |

I think your rifle is going to give you short case life if new cases have shoulder locations 0.027†back from the chamber. The basic rule of thumb is that cases are not to stretch more than .006â€. If you notice, most factory headspace tolerances fall within this range. The field gage is something the military uses, but they don’t reload. And they are trading off the probability of an accident with the real cost of a refurbishment. That’s a trade I won’t consider for myself as I do not consider myself expendable. On that first firing, your case is being stretched one heck of a lot. Since it is new brass, there is not much you can do to change that. I believe that the chamber edge creates a stress location in a belted magnum. You have this transition from sidewall chamber to a larger belted chamber and the exposed sidewall brass is going to try to expand and wrap around that edge. There is nothing you can really do about that. Overall in my opinion, the belted case is not a good design for reloading, perhaps just not a good design. The rims can interfere in the magazine and shoulder headspace varies widely between manufacturers. I am sure others could come up with more issues. As for case head separations, don’t over analyze. They happen even though you did everything right. I have shot enough to know that sometimes you will open the bolt, and out comes the case head, but not the rest of the case. I can recall a number of incidents happening to me particularly with IMI surplus in 30-06. I fired the ammunition in various rifles, Garands, M1903’s, etc. Then reloaded the brass with match bullets and fired it in match rifles. Every so often I would pull out a separated case . Don’t know why, I controlled by headspace with gages. I figure, bad cases. After a while I stopped using it in matches; alibis can ruin scores, and then you are wondering about your ammo instead of concentrating on sight alignment and trigger pull. | |||

|

| One of Us |

It is possible,however, that gas gets by the neck and the neck than seals. As the chamber barrel pressure goes down the trapped gas at a higher pressure deforms the case and escapes past the outside of the neck. Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| one of us |

Hey SlamFire, I do not mean this in a "mean spirited" way, but I disagree with every comment in your above paragraph. Apparently our experience with Belted Cases is totally different. Best of luck to you. | |||

|

One of Us |

Here are the measurements from a few of the rifles I reload for: Factory Rifle / New case / Once fired / Fully fire formed / Initial excess headspace Remington 22-250 / 1.577" / 1.586" / 1.5875" / .009" Pre-64 Win 264 / 2.109 /2.136 / 2.1385" / .0270" Wtby 7 rem mag / 2.101" / 2.125" / 2.140" / .0205" Steyr 30-06 / 2.040" / 2.0485" / 2.0515" / .0085" Mato 300 win mag / 2.253" / 2.270" / 2.272" / .017" Mato 338 win mag / 2.097" / 2.120" / 2.125" / .023" Custom barrel/chamber Hart 280AI / 2.135" / 2.150" / 2.152" / .015" Douglas 6.5 rem mag / 1.768" / 1.782" / 1.785" / .014" The 6.5 rem mag with the Douglas barrel was chambered by westpac who posts here, so if you want to tell him he did it wrong, lots of luck with that. I was right in the middle just like the Hart rebarrel. As you can see, I don't know where you get that .006" figure. Also, the excess headspace can depend upon the case manufacturer as well as the gun manufacturer. Go / No-Go gauge are not meant to tell you what your measurements are, just whether you are "in the ball park". Personally, I don't know how anyone could reload without a Stoney Point Head & Shoulders "thingy" ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Woods, that .027" excess headspace on your Pre-64, shouldn't that be .0027"? .027" is 0.89mm - which is huge! I must be thinking of something different. Headspace clearance should not be more than .0087" (0.22mm) surely? I found this on the internet;

Regards 303Guy | |||

|

| One of Us |

I do not understand this. If you are referring to cartridge headspace gages with their "Go" and "no go" marks, then I will disagree. The "Go" and "no go" locations on my .223, 6.5X55, 270, 308, 30-06 cartridge headspace gages all correspond exactly with my "go- No Go" chamber headspace gages. The fundamental problem I see with your measurement is your gaging technique. Stoney point gages are not calibrated to a standard. You are simply measuring things relative to each other. You have no idea if the new brass is within specification or not. And after firing, you are measuring some arbitrary point on the shoulder of the case and taking a measurement. The only "standard" I see is your rifle chamber. You are comparing dimensions before and after firings in your rifle chamber. To be fair, I do not remember what measurements I got, if I ever did it, when I dropped new cases in a Go- No gage cartridge headspace gage. Maybe later in the week I will give it a try, assuming I have any new cases around, and see if new cases are as below "go" as your measurements would make it seem. | |||

|

One of Us |

I don't have the pre-64 264 win mag anymore so let's go through the math on the 338 win mag which is similar with just a little less excess headspace: Okay, so let's go through this with pictures First always set the gauge to zero, which in this case is exactly set at 2"  take a new case  measure it with the gauge (using the collet specified by the gauge manufacturer) which in this case reads 2.097"  take a fired case, which in this example is twice fired and loaded (I don't have any once fired cases right now)  measure it and in this case it measures 2.123"  So, 2.120" - 2.097" = .023". Can you demonstrate where I am going wrong? Slamfire, you are correct in that the measurements are all relative but that does not make them false. The "thingy" manufacturer tells you which collet to use and if it is not on the shoulder datum point then it could not be far off. You are also correct that I do not know if the new brass is within specification or not. However, I have been doing this for years and I have a lot of data that shows that all the brass manufacturers have excess headspace built in and all guns that I have seen are similar to what I have posted. Please feel free to post your data and show us how you obtained it. I'm here to learn. How do you explain that the 6.5 rem mag I recently had done by westpac has an initial headspace of .014" when he specifically told me that he used Go / No-Go chamber gauges and it was perfect? Yes, there are probably some chambers that will only have .006" initial excess headspace with some runs of some manufacturer's brass but that is not what I have found so far. Show me, with pics please! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Thanks for clarifying Woods. I was indeed on a different page. I was thinking of the chamber headspace specs. You are talking about the case dimensions. Not exactly the same thing. Regards 303Guy | |||

|

| One of Us |

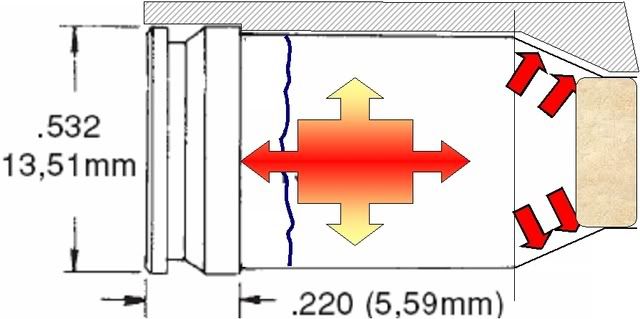

Hot Core, I believe your assessment of Slamfire's theory is correct.  The picture shows seperation is well forward of the belt.  I don't have very much experience with cartridge failure but it seems to me these are failing in tensile not radial stress, such as that which causes longitudinal tearing. Could failure be related to the shoulder gap? Wood’s data shows most of stretch is in the initial firing. Even if the cartridge did not fail it may have thinned the wall and failed on subsequent firing. What do you think? | |||

|

| one of us |

Hey pdpdad, And I agree with your thoughts. I always try to Fire Form my Cases on the "initial firing" to eliminate as much of the Stretch at the Pressure Ring as possible. Did not do it in my youth and had a good many Case Separations back then. I also agree with your thoughts there. And can take it just a bit farther, which Woods will love. As long as people continue to use the Thingys, and do not properly P-FLR, we will always have Case Head Separations to discuss. Of course, people Hunting in Dangerous Game country should always FLR and check their Cases for Insipient Case Head Separation when they Reload. | |||

|

One of Us |

Hey HC, my belief is that PFLR resizing can not be properly done without a "thingy"! Back at ya! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I was about to ask you if you had headspace gages for the 6.5 Remington Mag, then I looked it up. It is a blasted belted magnum. Since the belted magnums headspace off that belt, it can be within spec with "Go" and "No Go" gages. I suspect if you make a Cerrosafe casting of your chamber you will find that the reamer cut that shoulder way out there. I have picked up belted magnum cases that had case head seperations right at the belt. I assumed that the change in chamber dimensions was a contributor. Maybe it was due to other causes. Still, I don't like the belted magnum case design. There are a lot of cartridges that are based off the belted mag, basically blow up, necked down, but most of them date back to the early 60's. That is when shill gunwriters made everyone believe to have a magnum, you had to have a belt. If you look at recent cartridges, the trend is to drop the belt. Look at the huge Lazzeroni cartridges, http://www.lazzeroni.com/ct_lacart.htm the Winchester Short and Remington Ultra mags, http://en.wikipedia.org/wiki/List_of_rifle_cartridges. Can anyone think of a new, from the ground up case, developed since the mid Nineties, that has a belt? I am drawing a blank. | |||

|

One of Us |

Yes, the 6.5 rem mag is a belted case, and a nice little shortened version of the 264 win mag that will push 130 gr bullets at 3100 fps and 140's at 3000 fps without the overbore problems. So don't badmouth my new little 6.5 short mag Typically I load into the lands on the first firing and prevent thinning at the web that way. However, I was not into this when the 338 case that had the separation was first fire formed. How do you explain the Hart barrel having an excess headspace of .015" on Nosler 280AI new brass? How about the factory Steyr 30-06 or the factory Remington 22-250? None of those are belted. I submit that excess headspace on cases has as much to do with the brass manufacturer as it does the rifle manufacturer. Anyway, I have my explanation for the dent and have heard enough about case head separations for awhile. Wish I could talk HC into getting a "thingy" so he could figure out what he's been doing all these years! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Thanks for your illustration, pdpdad. If I may have an opinion (not an expert one), for what it is worth. From your illustration, I would suggest never full length sizing a belted magnum case. Firstly, why on earth would anyone want to headspace on the belt! More importantly, that belt is not going to survive too many 'headspacings' without some wear and tear (read excess headspace). Then, as shown, there is going to be too much clearance at the shoulder for the case to survive too long. I have checked up on belted magnum chamber and case specs and the shoulder learance is not designed for reloading. Regards 303Guy | |||

|

| one of us |

Hey Woods, Obviously I need to refresh your memory a bit. Hey 303guy, For a person Hunting in Dangerous Game country, it is a good idea to FLR whatever cartridge you are using to help avoid a jam if a bit of trash gets into the Chamber. That goes for ALL Cartridge Designs from the excellent Belted Designs to the other so-so Cartridges. You are correct and that applies to ALL cartridges that get FLRed. A person does need to check for Insipient Case Head Separations when they FLR "any" Case. I've no idea how you got that idea, but Belted Cases reload fine. Always have and always will - if done properly. I ran a Life Test on some 7mmRemMag cases, 25 or so years ago, with SAFE MAX Loads. I would shoot them, reload them and shoot again without Annealing. I got 33 Reloads on each of those Cases in the Test, by using P-FLR and finally had a Neck Split. Had I done some Annealing along the way, I'm sure it would have extended the Test, but I have no idea how much. That said, the same thing should be able to be accomplished with the inferior(Non-Belted | |||

|

One of Us |

I get that from cartridge and chamber specs. My 303 is the same. These cartridges just have looser tolerances around the shoulder area since they were not designed to headspace there. Alf did say he was F/L resizing and getting these failures after the 4th firing. So we are actually agreeing with each other! But hey, ..... it's those dents that are the mystery! Good Shooting! Regards 303Guy | |||

|

| One of Us |

I surrender | |||

|

| One of Us |

Wed. one of the second loaded cases had head separation. From what was witnessed it appears that all those cases, if used, will exhibit that failure mode. I have never understood the desire for an IMP. Hornet being the velocity gain is so small. Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| one of us |

| |||

|

| Moderator |

First and foremost, COMMERCIAL reamers and chambers are NOT DESIGNED to allow for reloading, they are designed to be safe with factory ammo. Woods,

I hate to tell you this, but if you are measuring the shoulder on belted brass, you are NOT measuring HEADSPACE. You are determining that the reamer's shoulder (not a datum) is sloppy .. the BELT is the headspace, and calling Malm out for a DANGEROUS .014 heaspace is uncalled for. If you want to compare this tool for what its DESIGNED for, as unfired brass has NO RELEVENCE to this discussion. Unfired brass is ALWAYS undersized, in every dimension. Don't bother arguing, just measure the case diameter of brand new brass, it's always small. Fire the brass , measure the result Set your dies -.002 from that result and your brass will last "forever" or 3 reloads, depending on your pressures. Alf's problem cases are over-resized, period. #dumptrump opinions vary band of bubbas and STC hunting Club Information on Ammoguide about the416AR, 458AR, 470AR, 500AR What is an AR round? Case Drawings 416-458-470AR and 500AR. 476AR, http://www.weaponsmith.com | |||

|

One of Us |

I know that headspace is measured to the point that stops forward movement, whether it is the front of the belt, the front of the rim or the shoulder. I was not calling malm out for dangerous headspace because I think he did an excellent job. That gun has less excess shoulder headspace than any other belted chamber I have and it is in no way dangerous. If you think it is, then you are the one who is dead wrong.

How can you say that new brass has no relevance to a discussion on case head separation. The gist of the whole discussion is that thinning at the web which is the precursor to case head separation happens on the initial firing of new cases. Who's arguing? We are discussing and actually exchanging information. Is there a problem with that?

.002" is usually too much, I set my shoulders back .001" for PFLR with the help of this tool, which it is designed for. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| Administrator |

Belted rifle chambers seem to be cut rather generously by the factories. I have no idea how many belted magnum rifle we have built, but, we do something the factories don't. And in theory, this could lead to some problems, but so far we have never had any. I never use a GO gage when chambering a belted magnum, but use a new case to check the heaspace. Our own rifles bolts will not close on a GO gage. I got this from a friend in the States. And when I first asked him wouldn't this lead to some factory ammo not chambering, he said he had never had that problem. At it seems he is right, as we have never had that problem either. The advantage I see is that we can load the same case many more times than we would have been able with factory chambers. And case ead seperation does not exist either. | |||

|

One of Us |

Saeed Excellent info and a good way to get around the problem. Thanks for constructive input. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia