The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Redding Body Die - 338 LM and maybe resizing too much?

Redding Body Die - 338 LM and maybe resizing too much?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

For .338 LM rifle I recently bought, I want to start to reload. I am pretty experienced in reloading, but only using FL sizing dies. Many different handgun and rifle calibers. For .338 LM, I bought Redding Competition Bushing 3- Die Neck Sizer Set. It includes Competition Bushing Sizing Die, The Body Die and Competition Seating Die. I also ordered Redding Competition Shellholder Set to be able to push shoulder just right enough. Everything seems really straightforward and simple to set and use. I also watched this video https://youtu.be/ldtbsym650k?t=37 and set and tried it the same way. I started with the "deepest" shellholder. But even with the "deepest" shelholder - it means the smallest resize possible, produced case has shorter headspace (or shorter rim to shoulder distance) than Lapua Factory ammo. I don't know if it is problem or not, I just want to have my ammo safe, accurate and working on brass as low as possible. Where should be the problem? I don't want to push shoulder as much as I do even with deepest shellholder. Can I leave a small space between die and shellholder and still have good consistency case to case? After this sizing, I do proper neck sizing with neck sizing die. BTW Already ordered new VLD stem for seating die, factory one is not designed for VLD bullets (what the hell anyone want to shoot from 338 LM anything else?) Thank you for any advice. Jiri | ||

|

one of us |

Maybe, there is quality issue with shellholders as I read here: https://www.midwayusa.com/prod...3?pid=525874#reviews I will measure them with micrometer and see. Jiri | |||

|

| one of us |

Hello Jiri, The most important length of headspace is what is in your rifle, not necessarily what the factory ammunition shows. When I am full length resizing for a particular rifle it is quite usual for there to be a slight gap between the shellholder and full length size die to make cartridges that fit, and this has never caused any problems. Other rifle and die combinations I have need the shellholder to touch the die, and a few (mostly older cartridges or rifles) have needed a bit of grinding on either the die or shellholder to work right. But in all situations, the dimensions of the rifle chamber are the determining factor. In an ideal world all dies and chambers (and ammo) would have exactly the same dimensions. We don't live there. | |||

|

one of us |

"The most important length of headspace is what is in your rifle, not necessarily what the factory ammunition shows." That is obvious. I just wanted to show that headspace (rim to shoulder distance) after slightest resizing possible (die set as manual says) is even shorter than factory rounds and it is ridiculous. "But in all situations, the dimensions of the rifle chamber are the determining factor. " Obvious too. Have you even watched the video I linked? I am looking for reason it happens. Faulty body die? Faulty shellholders? Will see. Jiri | |||

|

| One of Us |

Hi Jiri, I don't use bushing dies nor competition shellholders but am using Redding Dies and Big Boss Press. I FL size cases only. I don't know why your brass has oversized but if that happened to me I would simply back off the FL die ( or in your case, the Body Die ) until I was happy with he sized length. Then maybe you could select from the competition shellholders for any further fine tuning to get just the right amount of shoulder bump. I assume that if you end up with a small gap between the Body Die and Shellholder when the Body Die position is set you will still achieve sizing consistency. For my own sizing some FL dies just touch the shellholder, others have a small gap between. Never been an issue to me either way. Yes, the guy in the video says that "touching" is best for consistency, and that may be for the ultimate in accuracy but that's probably beyond my pay grade. I'm just handloading for hunting. Also, the video guy, settles on the #4 shellholder based on the feel of bolt closure on the sized brass. Personally I would have gone with # 6 or 8 shellholders. I like a little "feel" closing the bolt on a round. If later I feel the bolt closure getting tighter ( happens after a few loads using new brass ) I will adjust the FL Die down a part turn more until the "feel" remains constant with further sizing / shooting. Possibly could be some issue with the Redding components. From some of the comments it seems like some who contacted Redding found there was no issue after all. Good luck. Hope you git it sorted. Hunting.... it's not everything, it's the only thing. | |||

|

one of us |

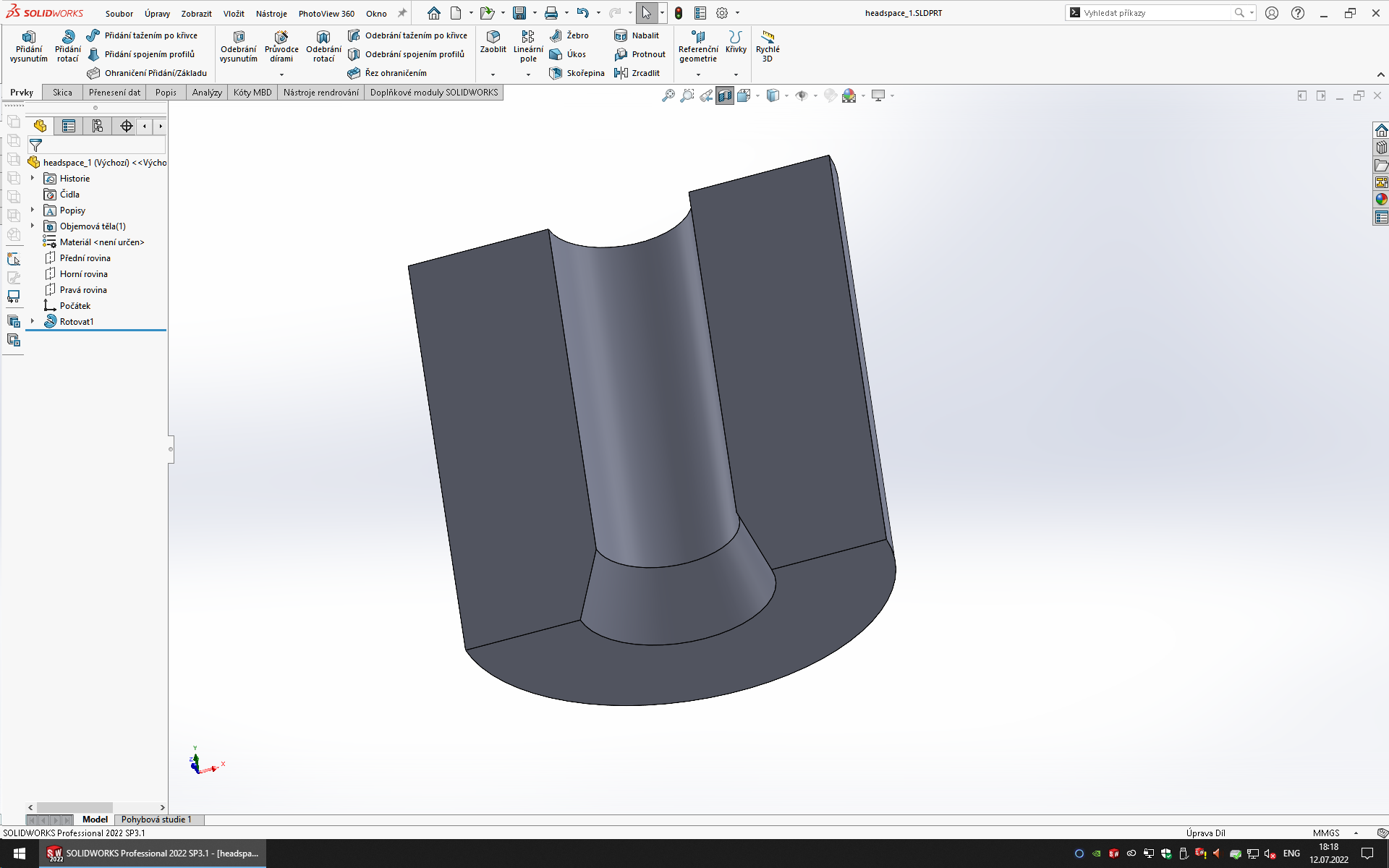

30.06king: "touching" is best for consistency - the same is in the manual for body die: Touch the shellholder, back the ram away from the die and add another 1/8 to 1/4 turn. Then maybe you could select from the competition shellholders for any further fine tuning to get just the right amount of shoulder bump. It is good idea. But I will measure shellholders first. I have also access to accurate CNC milling machine, so I can make shellholders by myself, but I expected no problems with Redding Competition products. BTW Ammo I want to make is for the rifle bellow.  It is long range rifle, so I have to step up from "hunting ammo" to "long range ammo". So far I have factory Lapua 250gr Scenar ammo (bad for hunting) and those bullets: Hornady A-Tip 300gr - maybe for hunting Peregrine VLR4 248gr - for LR hunting Cutting Edge Lazer 250gr - for LR hunting too Jiri | |||

|

One of Us |

I get that you have read or seen video's of the "best" way to set up your redding dies. If your not happy with them I would send them back as it sounds like something is wrong with how they are working with their shell holder set. With your "deepest" shell holder what is the headspace difference between a fired case? If a new case chambers in your gun I sure as hell would not want to be bumping the shoulder any further. I would set the sizing die so it is bumping the shoulder .0015-.002". Then measure the case run-out to see if you have an issue. It is rare that I have any of my dies set up to touch the shell holder. And even more rare that after properly setting up dies that run-out is an issue. Most of our rifle ammo is loaded on a Forstner press so that float in the dies helps a lot IMO. Mac | |||

|

one of us |

McKay: Send them back - friend bought that dies and shell holder set for me at MidwayUSA and his wife brought that dies to me when she visited Czech Republic. I believe nothing is wrong with dies, but shellholders are junk. I don't care anymore. I have Redding Ultramag press (bought mostly for .585 HE) and Forster Co-Ax. So I will try "no contact" method and will set it on my Forster. Difference between new and fired case I have to measure, but not have done it yet. I will lathe turn or 3D print tool for that. Jiri | |||

|

one of us |

It will be sufficient, just will 3D print it. It will not be for absolute measurements, but will be enough for measuring differences. Also for factory or loaded ammo.  | |||

|

One of Us |

This might be a little easier. They also sell it in pieces if you don't want a set. https://www.midwayusa.com/prod...012743827?pid=479704 Edit* Just noticed you are not from the US, so probably not easy! Mac | |||

|

one of us |

McKay: It is easy to 3D print that simple tool. Jiri | |||

|

one of us |

Update: I already 3D printed the tool, found it too bulky, so lathe turned brass one. Much better and easy to use. Factory ammo has shoulders set back against fired cases 0.12 mm (0.0047"). For "deepest" shellholder and contact method, it is 0.15 mm (0.0059"). My goal is somewhere between 0.001-0.002", so about 0.025 to 0.05 mm. Will try "no contact" method and will see the consistency. Jiri | |||

|

one of us |

No contact method in Forster press yields 0.05-0.06 mm constant shoulder set back. So I am happy here. Now, with neck sizing: I know how to choose right neck bushing size, but how to set best neck sizing depth? Jiri | |||

|

| One of Us |

Thanks for reporting the shoulder set back in your Forster press is quite constant. It would surprise me if it wasn't but still makes me feel good about the "no contact" FL sizing with my Redding press as I guess it works the same. For your question re "how to set best the neck sizing depth", will you be using a Redding Neck Sizing ( only ) Die with insertable bushings ? Or do you mean trying to figure out what neck sizing depth is best for a particular load ? Hunting.... it's not everything, it's the only thing. | |||

|

one of us |

30.06king: I will use Competition Bushing Sizing Die, that one with micrometer adjustment and insertable bushings. I know how to select proper bushing for optimal neck tension, but I am not sure how far/deep I have to size the neck. My logic tells me to size whole neck, but maybe, there can be some advantage to size just part of the neck. Not sure here because until this .338 LM, I always used common FL dies for hunting reloads. Jiri | |||

|

| One of Us |

None of my cases have headspace, I am not infatuated with head space, I want to know the length of the chamber from the datum to the bolt face (and then there are rimed cases and belted cases for belted chambers and rimed chambers). Once I have determined the length of the chamber from the datum to the bolt face, I can measure the length of the case from the shoulder datum to the case head to determine clearance. Reloaders do not have clearance, if they did, they would not be having so much difficulty in selecting the correct competition shell holder. I have one set of competition shell holders. I paid $5.00 for it at the Mesquite Gun show. What did I do before I purchased that set? Anything I can do with a Redding Competition shell holder I can do with a feeler gage, with the exception of chambers that require +.010 adjustment of the die off the shell holder (for example) I have a M1917 with a long chamber, the chamber on that rifle has a chamber that is .016" longer than a full length/ sized/minimum length case. When sizing cases for that rifle I adjust the die off the shell holder .014" for a clearance of .002". I off set the length of the chamber with the length of the case from the datum to the bolt face. F. Guffey | |||

|

| One of Us |

All of my shell holders have a 'deck height', the difference in deck height for the 5 competition Redding shell holders is .010". I have one set for belted cases, one shell holder is off by .001". F. Guffey | |||

|

| One of Us |

I called Redding and asked them how they convinced reloaders it is possible to size the body of a case without sizing the case from the shoulder to the case head? The die must have a shoulder to facilitate sizing the body of the case. F. Guffey | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Redding Body Die - 338 LM and maybe resizing too much?

Redding Body Die - 338 LM and maybe resizing too much?

Visit our on-line store for AR Memorabilia